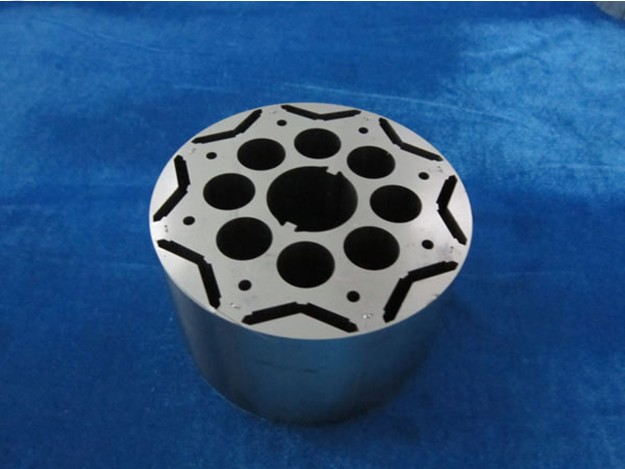

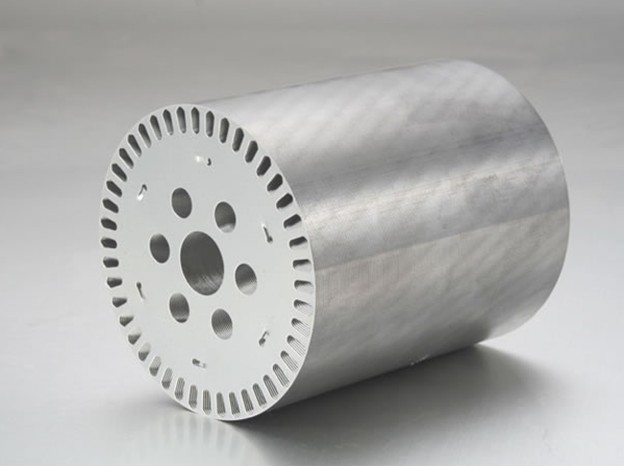

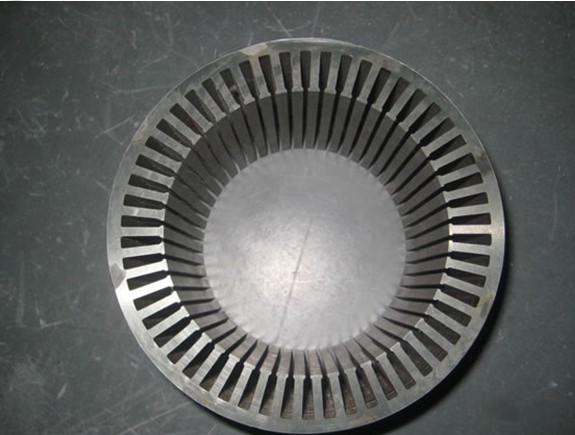

Torque Motor Stator Core - NO

Torque Motor Stator Core For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Torque Motor Stator Core, Made in China, High Quality Products!, China Electric Motor Parts, Electric Motor Stator Core Supplier, Manufacturer.

Product Description

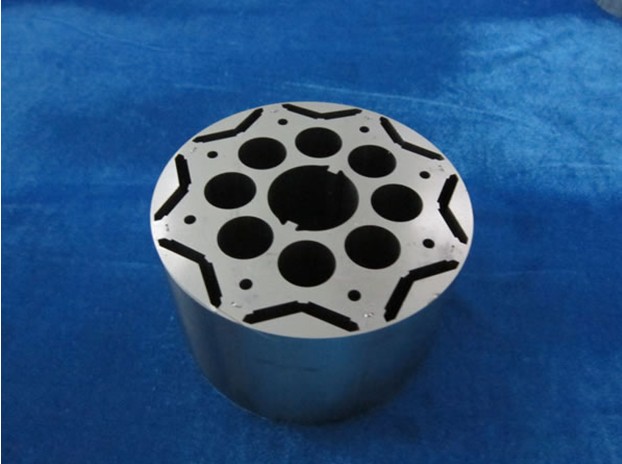

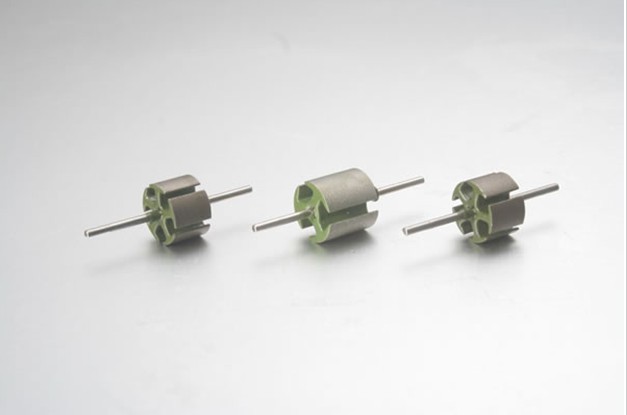

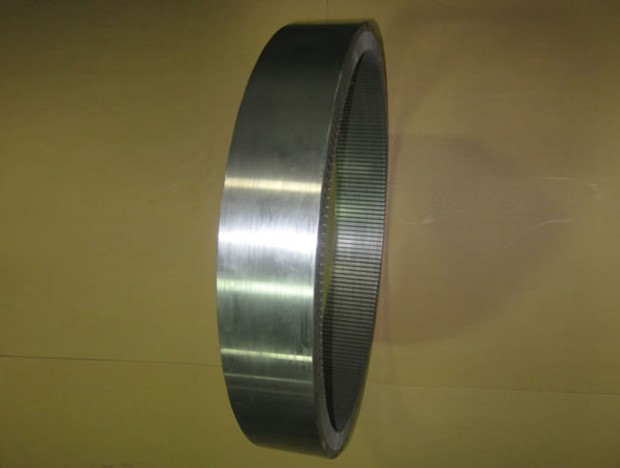

We have been focusing on the torque motor stator core for over 10 years, and our product has already been exported to Western Europe and America. The maximum diameter of the product can reach 1.15 meters. Our advanced equipment from abroad ensures the higher precision and lower thickness of the product. Generally, welding method is used for lamination stacking, and fine turning process is applied to the outer core for better appearance.

We are capable to offer OEM service. On the basis of our experience and actual practice, we will deeply discuss with clients about their drawings and requirements on torque motor stator core, so that the most optimal product can be achieved. The production is conducted afterwards.

For more service information, please contact us.

http://www.phasemotors.com/electric-motor-stator-core/1222564.html

http://www.phasemotors.com/electric-motor-stator-core/

Phase Industrial Design Ningbo CO., Ltd.

Address: Room 1203, Fengting (F) Building, Hefeng Chuangyi Square, No.375 JiangDong North Road, JiangDong , Ningbo, Zhejiang, China, Ningbo, Zhejiang, China, 315800

Tel: 86-574-27809638

Phase Industrial Design Ningbo Co.,Ltd. is a state-level high-tech enterprise, the production center is located in Hangzhou Bay New Zone of Ningbo, and the sales office is in Ningbo city center; the company was established in 2001, to undertake professional foreign customization motor, motor parts and magnetic device processing production and assembly. The company has self-import and export rights, our customers are mainly distributed in Europe and North America and other countries. Ningbo Phase has accumulated more than 10 years of practical operation experience in magnetic assembly technology and electrical motor manufacturing. We can provide improvement proposal on customer`s design combining with actual production and clients technical communication in order to produce the best combination of theory and practice; especially in the early stages of the products development, we can simulate or optimize the customer`s mechanical design by drawing on the 3D (Solid works and Pro E) graphics software, to select different production ways with the least input to make out the samples.

www.phasemotors.com