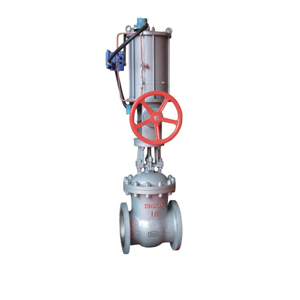

the power station electric and welding globe valve - J961Y

the power station electric and welding globe valve For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale the power station electric and welding globe valve , Made in China, High Quality Products!, China power station valve, globe valve Supplier, Manufacturer.

Overview:

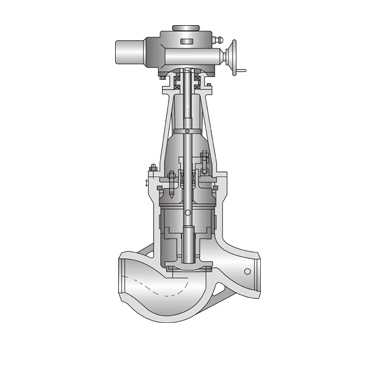

1. The body and bonnet link forms: PN10-64 using bolted bonnet; PN64-320 using the pressure sealed cover.

2. Stem nut: under normal circumstances, stem nut materials using ASTM A439 D2, at the same time can be based on user require the use of copper alloy materials, such as for large caliber cut-off valve, rolling bearing, can effectively reduce the cut-off valve open torque can easily switch valve.

3. Stem design: the whole forging process, in accordance with the standards to determine the minimum diameter.

4. The valve cover gasket form: PN10-64 cut-off valve adopts stainless steel graphite winding gasket; PN100 globe valves are available in stainless steel graphite winding gasket can also use a metal ring gasket; PN160 cut-off valve can be used metal ring gasket, PN320 cut-off valve adopts the pressure seal metal ring.

5. Stop valve structure features: bolted bonnet, rising stem yoke and lift stem metal cover.

6. Back seat design: our company provides all globe valve seal design, under normal circumstances, the carbon steel globe valve seat design USES separate sealing structure, stainless steel valve& acute;s sealing face is very reliable. Although have pour sealing according to the standard API600, but it& acute;s not as the basis of in case bring pressure change filler.

7. Packing: usually adopt forming flexible graphite as filler material, can according to user requirements to provide PTFE or compound packing materials. Packing and stuffing box contact surface roughness is 3.2 u m, can ensure that the valve stem and packing interface bonding tightly but is free to rotate to a precision machining of the valve stem sealing surface roughness of 0.8 u m can ensure the valve stem seal.

8. The seat: carbon steel globe valve seat usually using forged steel materials, valve seat sealing surface spray welding carbide according to customer demand, NPS 10 or less & quot;by using separate thread screw-plug seat.

ZheJiang Hisun Automation Instrument Co.,Ltd

Address: He yi Industrial Zone,Oubei Town, WenZhou, ZheJiang, China, 325105

Tel: 0086-577-57789961

ZheJiang Hisun automation instrument Co.,Ltd. is a valve company which integrates Researching, manufacturing, designing,sales and after services as a specialized unit. This company is located beautifully in the scenery, scenery joy person's China "township of the pump valve" north the Wenzhou cup the pump valve garden area, the transportation is convenient,the industry is centralized. We produce "HISUN" brand valve , quality reliabled, variety is completed with nothing .We took the lead among our peers in China in obtaining TS manufacturing license, ISO9001 certification, CE

certification, API certification .The company according to ISO9001 manufacture standard strict. We to rely on Science and technology, we are innovated exertion all the time, exploitation various "HISUN" brand valves and we can according standard , material or drive way to design and produce high quality valves.The products of HISUN is protected for ahead of technique and manage, In accordance with the marketing philosophy of "all for users", we will application new technique , new technics ,new materials unceasingly to to open up and develop new products, we will provide better products and serve, there will be more efforts to construct modernization "HISUN".

Established in 2015,As a control valve supplier specialized in designing and manufacturing high-end control valves and serving high-end customers.In addition, we have various advanced equipment needed for manufacturing control valves

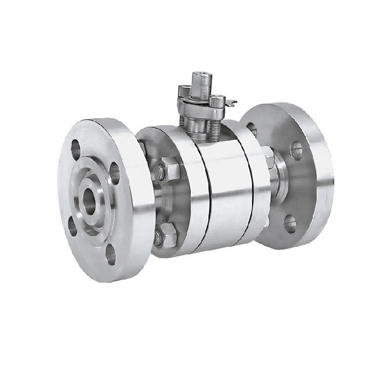

and nationally advanced control valves flow testing systems.Our products:linear motion control valves, self-operated control valves,ball valves,power station valves, butterfly valves. pneumatic actuators,

Our goals:

---creating value for customers

---creating value for investors

---creating value for society

---creating value for personnel