Structural Profile Roll Forming Machine - ZT-006-33333

Structural Profile Roll Forming Machine For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Structural Profile Roll Forming Machine, Made in China, High Quality Products!, China Profile Forming Machine, Structural Roll Forming Machine Supplier, Manufacturer.

Structural Profile Roll Forming Machine

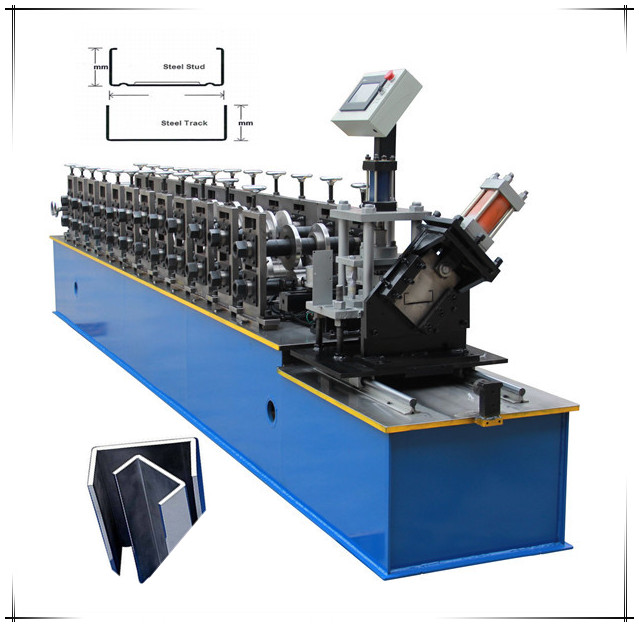

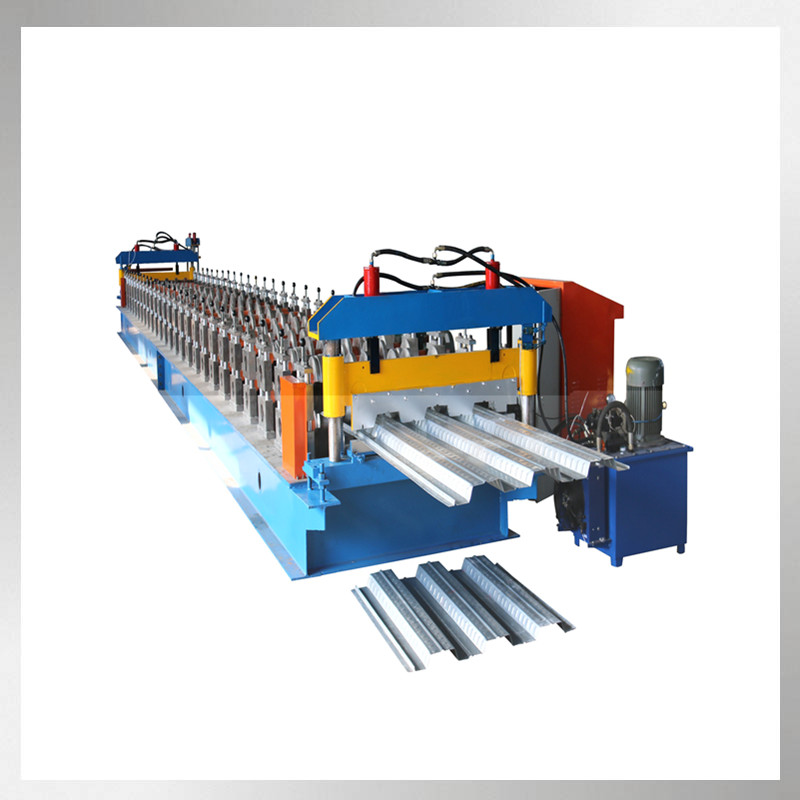

One machine can produce different sizes of purlines.

Main Technical Specifications:

Material: Carbon steel

Material Thickness:1.5-3mm

Landscape orientation adjustment range of Hole distance : 45-500m

Length of purlin: >3m

Forming Stations: 17 Main rollers

Leveling Stations: 7

Feeding Stations: 2

Main Power: 15KW

Machine Diameter: About 12500mm(L)x2300mm(W)x1600mm (H) ( including main motor )

Weight of machine: about 15 Ton

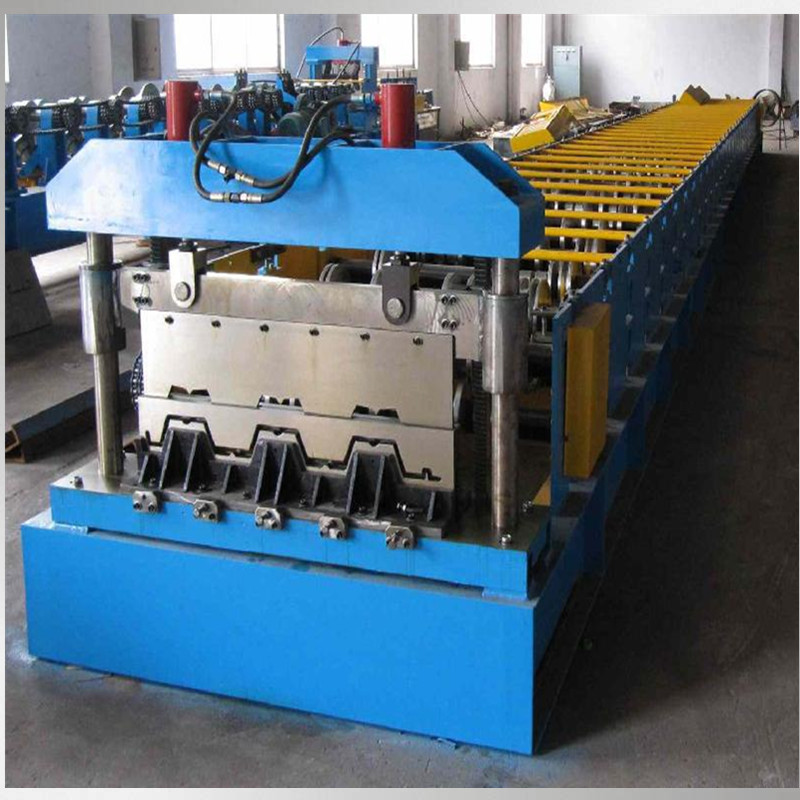

One machine can produce different C/Z Purlins through simple manual st adjustment, when to produce different profiles, no need to change the forming rollers. In the process, machine adopt automatic control model, it can auto punch, cut, forming based on inputting length of purlin, portrait hole distance, quantity, etc datas.

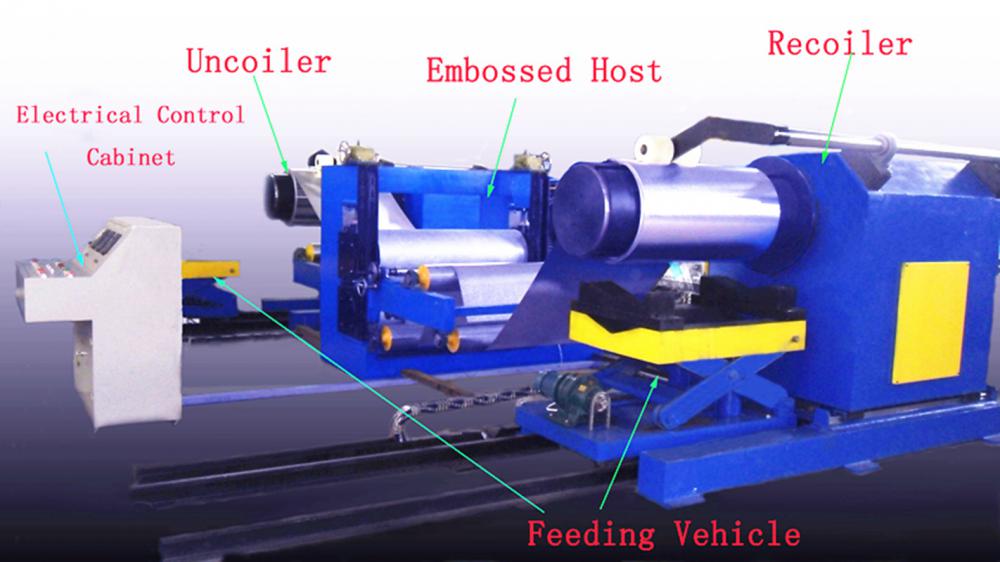

C/Z purlin roll former make up of decoiler, feeding, leveling, 2 sets hydraulic punching device, hydraulic cutting, speediness interchangeable forming machine, PLC control system, hydraulic stations, run out tables.

This line main forming drive adopt reducer motor and frequency conversion control, speed control-

Product application of C shape purlin roll forming machine

They are widely used as the supporter of roof and wall in large-scale and mid-scale construction, such as factory, warehouse, garage, exhibition center, cinema, theatre, garden and so on.

Our Metal CZ shape Purlin Roll Forming Machine`s advantages

1. Anti-rust roller: Cr12 mould steel with quenched treatment, long life time.

2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation.

3. Cutter blade: Cr12 mould steel with quenched treatment, long life time.

4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance.

5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction.

6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines.

7. All-in-house source: We are & quot;All-in-house source& quot; factory to ensure quality and delivery of your machines.

8. Long life: Ensure you our produce machine`s lifetime more than 15 years.

It is quick and easy to operate the machine, and beautiful appearance, high production efficiency, forming speed up to 20m/min.

Get Quote

Cangzhou Zhongtuo cold bending forming equipment manufacturing co., LTD

Address: Room 807, Building 6, Taida International,Yunhe district, Cangzhou City, Hebei province, China , Cangzhou, Hebei, China,

Tel: 0086-317-2191158

Cangzhou Zhongtuo cold bending forming equipment manufacturing co., LTD from 1996. We are specialized in manufacturing color steel forming machine,light keel machine,C&Z purlin machine,Glazed tile forming machine,welded tube mill, stone coated roof production line,steel structural floor panel roll forming machine and so on. We also have the derivatives and raw material. We real provide you one station, non-stop service,Now,our machine have been exported to 30 countries,such as Canada,South Korea,Russia,Holland,Sri Lanka,Malaysia,India,Brazil,etc.Our company insists on the service aim: Quality First,Credit First. We believe that we can make the future cooperation and achieve win-win.

http://www.rollsformingmachines.com

http://www.rollsformingmachines.com