Steel Castings Wear Liners For Mine Mills With HRc33~42 DF077 - DF077

Steel Castings Wear Liners For Mine Mills With HRc33~42 DF077 For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Steel Castings Wear Liners For Mine Mills With HRc33~42 DF077, Made in China, High Quality Products!, China cheap prodocuts, china suppliers Supplier, Manufacturer.

Steel Castings Wear Liners For Mine Mills With HRc33~42 DF077?

?

? Quick Details

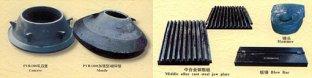

Wear Cast Liners for Mine Mills?Feature:

1.Wear Cast Liners have popular & safer application in Australian mines;

2.Steel castings can be used stably in large mine mill

? China mill liners supplier provides ball mill liner services to worldwide ball?mill liners customer. Hope you find our mill liner process and grinding mill liners product description helpful. ?

Wear Cast Liners for Mine Mills?Description:

a.??The hardness for Pearlitic CrMo Cast Steel Cap: HRc33~42 (HB310~390); Steel caps shall be sample hardness tested at approximately ten percent(10%) random selection;

?

b.??Microstructure: Predominantly pearlite;

c.??Chemical Composition: Every furnace heat shall be analysed by Spectrometer; A conforming sample shall be obtained from each furnace heat prior to pouring the mould(s);

?

d.??Dimensional Checking & Gauging: 100% check; be compliance to drawing dimensions within specified tolerances;

1.??By visual inspection, e.g. where a cross joint or other dimensional or shape defect is evident, dimensions shall be verified to drawing;

2.??By gauges manufactured to check specific features or dimensions of individual casting;

?

e.??Casting Soundness: Level 2 of AS2574 or equivalent standard, 10% of order selected at random to be free of shrinkage with UT; Assessment of casting soundness and internal integrity shall be by ultrasonic testing; Sectioning by cutting may be only be used as a macro view test, as the cutting process may remove the area of unsoundness;

?

f.??Surface Finish: Visual inspection after shot blasting; To achieve an acceptable level of surface texture, freedom from defects and extraneous material or rust that have the potential to reduce wear-life or the effective bonding of a rubber product;

1.??All wear surface to be free from surface defects that may affect fitness for purpose, and any from of grease or oil;

2.??All wear surface to be free from any raised features or markings above the wear face;

3.??All bonding surface to be free of defects that affect fitness for purpose and to be free of rust, scale and any form of grease or oil.

g.??Reporting: Providing process, inspection & test result data by which

specification compliance can be traced.

1.??To provide process, inspection and test result data by which specification compliance can be traced;

2.? To provide a means by which steel cap performance, may be correlated to manufacturing data with respect to chemical composition, heat treatment, and hardness.

h.?Wear casting liners?for?mine?mills.

? ?

Technical?Parameters

?

?

Our?foundry?has?complete?melting,?heat?treatment?and?test?equipments,?such?as?mid-frequency?induction?electrical?furnaces,?quenching?and?tempering?furnaces,?blast?shot,?spectrometer,?Rockwell?and?Brinell?Hardness?tester,?impactor,?UT?tester?and?metallographic?microscope.?We?achieved?the?certificate?of?quality?management?system?ISO?9001:2008.?We?have?been?exporting?castings?to?oversea?markets,?such?as?Brazil,?Australia?and?South?Africa.

?

?

Foundry?Photo

?

?

?

Wuxi Orient Anti-wear Engineering Co.,Ltd

Address: Zhongyao,Xishan District, Wixi, Jiangsu, China, 214000

Tel: 86-510-88798440

Wuxi Orient Anti-wear Engineering Co., Ltd.

We specialize in production of wear, heat and corrosion-resistant castings and the relevant grinding equipments. We were awarded the certificate of High New Technology Enterprise issued by Sci-tech Bureau, Jiangsu Province in 2004.

We possess famous patented product----COMBINED SELF-FASTENED (BOLTLESS) BALL MILL LINERS, called "China Best Liner", which was invented under the guidance of the 鈥淪ystem Engineering Theory of Ball-Mills鈥? which was proposed by General Manager, Senior Engineer, Mr. Chen Changshun. The lining plates, without any bolts, are easily installed. The plates are firmly assembled and easily maintained under a low cost. This is an epoch-making ball mill liner product in the past 100 years. The reliability and stability of the new plates are much better than those of traditional bolted ones. In the recent 20 years the boltless ball mill liners have been widely used in large, medium and small ball mills in coal-fired power plants, mines, cement works, chemical engineering factories and super fine powder grinding plants. It is the only recommended liner product which is allowed to be list into the latest Electrical Power Industry Standard in China (DL/T681-1999). The product was awarded the certificate of High New Technology Product, issued by Sci-tech Bureau, Jiangsu Province in 2004.

Our products involve various kinds of materials, such as low Chrome alloy steel, middle Chrome alloy steel, high Chrome alloy steel, high chromium white iron, low chromium cast iron, Ni-hard cast iron, high Manganese steel and other heat and corrosion-resistant castings.