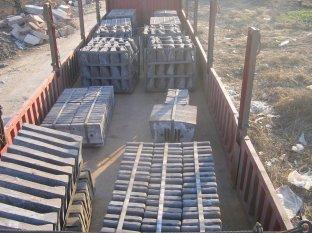

Steel Caps Moulded In Rubber Aluminum Sand Castings With HRC33~42 DF078 - DF078

Steel Caps Moulded In Rubber Aluminum Sand Castings With HRC33~42 DF078 For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Steel Caps Moulded In Rubber Aluminum Sand Castings With HRC33~42 DF078, Made in China, High Quality Products!, China cheap prodocuts, china suppliers Supplier, Manufacturer.

?

Steel Caps Moulded In Rubber Aluminum Sand Castings With HRC33~42 DF078

?

Quick Details

1.Steel Caps have popular & safer application in mines;

2.Steel castings in rubber liners can be stably used in?large mills.

Steel Caps Moulded in Rubber Liners?Description:?

1.??The hardness for Pearlitic Cr-Mo Cast Steel Caps: HRc33~42 (HB310~390); Steel caps shall be sample hardness tested at approximately ten percent(10%) random selection;

?

2.??Microstructure: Predominantly pearlite;

3.??Chemical Composition: Every furnace heat shall be analysed by Spectrometer; A conforming sample shall be obtained from each furnace heat prior to pouring the mould(s);

?

4.??Dimensional Checking & Gauging: 100% check; be compliance to drawing dimensions within specified tolerances;

4-1.??By visual inspection, e.g. where a cross joint or other dimensional or shape defect is evident, dimensions shall be verified to drawing;

4-2.??By gauges manufactured to check specific features or dimensions of individual casting;

?

5.??Casting Soundness: Level 2 of AS2574 or equivalent standard, 10% of order selected at random to be free of shrinkage with UT; Assessment of casting soundness and internal integrity shall be by ultrasonic testing; Sectioning by cutting may be only be used as a macro view test, as the cutting process may remove the area of unsoundness;

?

6.??Surface Finish: Visual inspection after shot blasting; To achieve an acceptable level of surface texture, freedom from defects and extraneous material or rust that have the potential to reduce wear-life or the effective bonding of a rubber product;

6-1.??All wear surface to be free from surface defects that may affect fitness for purpose, and any from of grease or oil;

6-2.??All wear surface to be free from any raised features or markings above the wear face;

6-3.??All bonding surface to be free of defects that affect fitness for purpose and to be free of rust, scale and any form of grease or oil.

7.??Reporting: Providing process, inspection & test result data by which

specification compliance can be traced.

7-1.??To provide process, inspection and test result data by which specification compliance can be traced;

7-2.? To provide a means by which steel cap performance, may be correlated to manufacturing data with respect to chemical composition, heat treatment, and hardness.

?

In the recent 20 years, our liners have been widely used in large, medium and small ball mills in Chinese power generation, mining, cement, Chemical engineering and metallurgical industries and super fine pulverizing equipments. It is the only recommended liner product in the latest standard of the electric-power industry in China.

?

Technical Parameters

Wuxi Orient Anti-wear Engineering Co., Ltd.

Chemical Composition & Mechanical Property of Wear-resistant Castings

?

- - - -

Item | Cr-Mo Alloy Steel I | Cr-Mo Alloy Steel II | Cr-Mo Alloy Steel III | High Cr white iron | High Cr Alloy Steel | High Manganese Steel | Ni-Hard cast iron |

C | 0.30~0.50 | 0.65~0.90 | 0.40~0.90 | 2.40~3.20 | 1.1~2.2 | 0.90~1.30 | 2.40~3.60 |

Si | 0.50~1.20 | ≤0.75 | 0.70~1.20 | 0.60~1.20 | 0.60~1.20 | ≤0.08 | ≤0.80 |

Mn | 0.40~1.20 | 0.50~1.20 | 0.60~1.00 | 0.50~1.00 | 0.50~1.00 | 11.00~18.00 | ≤2.0 |

Cr | 1.70~2.50 | 1.50~2.50 | 4.00~7.00 | 12.00~30.00 | 11.00~30.00 | 1.50~2.50 | 1.5~10 |

S | ≤0.04 | ≤0.06 | ≤0.04 | ≤0.04 | ≤0.04 | ≤0.04 | ≤0.15 |

P | ≤0.04 | ≤0.06 | ≤0.06 | ≤0.06 | ≤0.06 | ≤0.06 | ≤0.15 |

Mo | ≤0.5 | ≤0.5 | ≤0.5 | 0.10~3.0 | 0.10~3.0 | ≤1.0 | ≤0.10 |

Cu | 0.10~0.60 | ≤0.25 | 0.20~0.40 | 0.10~1.00 | 0.10~1.00 | - | - |

Ni | ≤0.50 | ≤0.30 | 0~0.30 | 0~0.30 | 0~0.30 | - | 3.3~10 |

Re | ≤0.02 | ≤0.02 | ≤0.02 | - | - | - | - |

Equivalent Specifications | DL/T 681-1999 ? GB/T26651-2011 | AS 2074 L2B Mod | DL/T 681-1999 | GB/T 8263-1999 AS 2027 Cr27 AS 2027 CrMo 15/3 AS 2027 CrMo 20/2/1 ASTM A532 Class III type A 25% Cr ASTM A532Class II type B 15% Cr-Mo BS 4844 3E DIN1695 NFA32401. | GB/T 5680-1998 DL/T 681-1999 JIS G 5153-1999 ASTM A 128 DIN GX120Mn12 AFNOR:Z120Mn12 | GB/T 8263-1999 AS 2027/Ni-Cr1-550 AS 2027/Ni-Cr2-500 AS 2027/Ni-Cr4-500 AS 2027/Ni-Cr4-600 AS 2027/Ni-Cr4-630 ASTM A 532 1-A,B,C,D ASTM A 532 2-A,B,C,D,E ASTM A 532 3-A |

Material Type | Martensite Steel | Martensite or Pearlitic Cr Mo Steel | Martensite Steel | Martensite matrix | Austenitic Mn Steel | - |

Hardness | HRc≥48 | HB470 & HB 321~370 | HRc≥50 | HRc≥56 | HB≤300 | HRc≥56 |

Impact Value | Ak≥40J | - | Ak≥10J | Ak≥4J | Ak≥80J | - |

- - - -

?

Our foundry has complete melting, heat treatment and test equipments, such as mid-frequency induction electrical furnaces, quenching and tempering furnaces, blast shot, spectrometer, Rockwell and Brinell Hardness tester, impactor, UT tester and metallographic microscope. We achieved the certificate of quality management system ISO 9001:2008. We have been exporting castings to oversea markets, such as Brazil, Australia and South Africa.

?

Wuxi Orient Anti-wear Engineering Co.,Ltd

Address: Zhongyao,Xishan District, Wuxi, 214000, Jiangsu, China, Wuxi, Jiangsu, China, 214000

Tel: 86-510-88791954

High Chrome white iron we can produce include 15Cr, 18Cr, 20Cr and 26Cr. Under same working condition, the wearperformance of High Chrome mill liners is four times of that of high manganese steel liners and twice of that of low Chrome alloy steel liners.