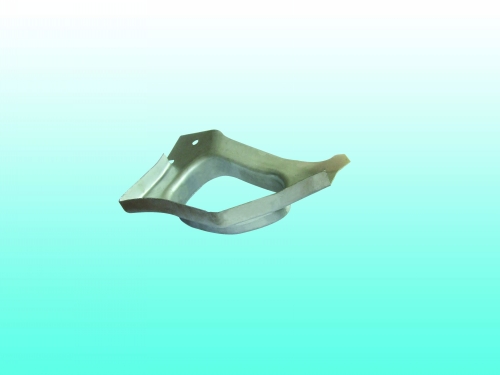

stamping parts - ZJ001

stamping parts For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale stamping parts , Made in China, High Quality Products!, China auto parts, stamping parts Supplier, Manufacturer.

We manufacture precision metal stamping part according to customer's demands and we accept OEM/ODM service for stamped parts.

Precision stamping processing: 6.3-125T pressing/punching machines, NC bending, NC shearing, welding, milling.

* Materials: Can be Cold roll steel (SPCC), SPHC, SECC, AL1100, AL5052, AL6063, SUS301, SUS304, BECU, PBS or SPTE.* Product weight: From 0.010 to 10kg/pcs* Metal stamping and punching for Over 10 years* Further machining work: Cutting, milling, grinding, drilling and reaming and threading* Surface finish process: Polishing shot blasting, chrome plating, powder coated and anodizing* OEM/ODM parts range: Auto parts, electronic parts, furniture parts, home appliance and other industrial uses* Processes: Pricision metal stamping, other machining processing, surface plating, QC testing and packaging* Made according to customer's drawings, specifications and/or sample* Products shown on the website are OEM/ODM stamped parts

Zhongjing Group Co.,Ltd

Address: International Auto & Motorcycle Parts Industrial Zone,, wenzhou , Zhejiang, China, 325204

Tel: 86-577-65323530

Established in 1986,Zhongjing Group Co.,Ltd.,is located in the international Automobile&Motorcycle Parts Industrial Zone,Rui'an,Zhejiang,adjoing to No.104 national way,only 800m away from expressway exit,20km from Wenzhou Airport.

We specialized in manufacturing auto-mobile stamping parts and motorcycle punching parts,fine blanking parts and c-hassis parts including auto cover parts, auto door hinges auto bumps,brackets,flanges etc..With the rapid development in the past 20 years,the total capital of Zhongjing Group has run up to 0.25 billion RMB.In addition, by the arduous efforts of all staffs,Zhongjing had ranked top 30 enterprises in Rui'an city of Zhejiang Province in 2004.

It has 635 employees including 5 senior engineers,8 engineers,12 assisstant engineers,2 economic engineers and 7 senior egineers mould engineers,59﹪ employees were well-educated over the vocational secondary schools or higher.

As Zhongjing people believe the quality is the root of the survival and development of the enterprise,Zhongjing successfully acqired the certificates of ISO9001-2000 in Nov.2004 and ISO/TS16949-2002 in Aug.2007,and its automobile door hinges passed 3C certifications in 2006.

With strong ability of product research and development,Zhongjing adopts the worldwide popular computer 2D and 3D auxiliary desingn software for mould shaping design,meanwhile, the company possess FV-1000 and VB-715 high accuracy CNC centers,many electrosparking NC wire-cutting machines like DK7780 and 315T,500T,and 800T hydraulic machines,216 units of large and medium-sizes punching equipments and 100T,125T,200T and 400T punches.

What抯 more, the company has invested 1million RMB to purchase in inspection equipments, such as coordinate measuring machine,salt spray tester, carbon-sulfur analyzer, Breinell hardometer, Rockwell hardometer, anylysis scal, airtight checkout equipment,ect.,