Stainless Steel Stamping Auto Sheet Metal Parts Galvanized Professional - AIA-1

Stainless Steel Stamping Auto Sheet Metal Parts Galvanized Professional For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Stainless Steel Stamping Auto Sheet Metal Parts Galvanized Professional, Made in China, High Quality Products!, China cheap prodocuts, china suppliers Supplier, Manufacturer.

Stainless Steel Stamping Auto Sheet Metal Parts Galvanized Professional

?

Packaging & Delivery:

?

- - - -

Packaging Details | lastic bags for inside packing;?

small custom-made cartons for inside packing;?

big hard carton for outside packing;?

pallet packing for shipping;?

or as per your requirements |

Delivery Detail | 10-20days |

- - - -

?

Detailed Description?:

?

?

- - - -

Specification |

Material:?spring steel |

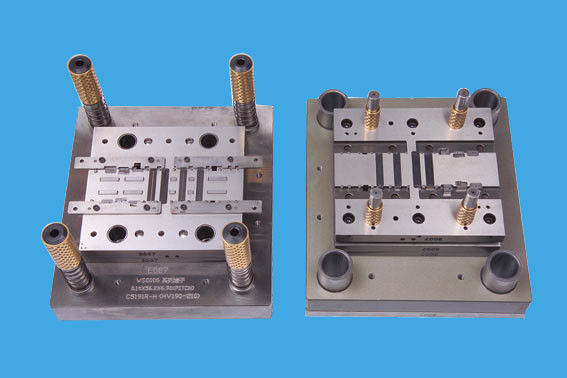

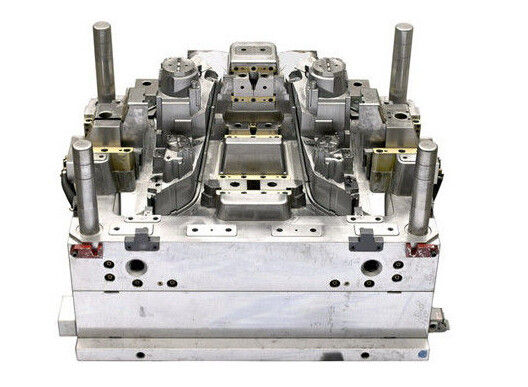

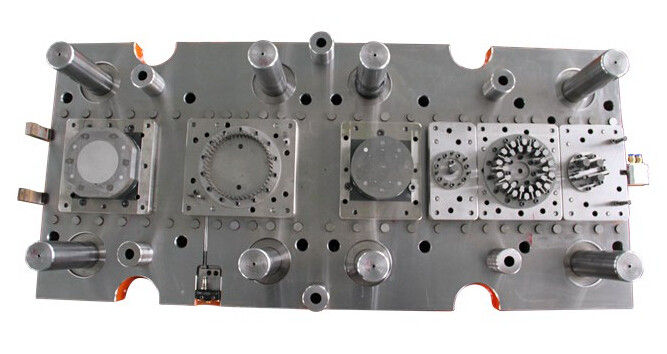

Process:?metal stamping |

Colour:?zincor as per your requiremant |

Finish: ?zinc?plating |

Size:?as per your design&drawing |

Price:0.0001-0.0002USD/PCS |

MOQ:100pcs |

Certificate:SGS |

OEM order:welcome very much |

Port:shenzhen |

Payment type:?TT/paypal/LC/western union |

Packaging Details:?plastic bags for inside packing;;small custom-made cartons for inside packing;big hard carton for outside packing;pallet packing for shipping;or as per your requirements |

? Advantage |

1 . OEM manufacture |

2 . Comprtitive price |

3 .?Fast and timely delivery |

4 . Superior quality&long life performance |

5 . Small order can be accept |

6 . Speedily&professional service(reply e-mail within 3 hours) |

7 . Give customer professional suggestion while in the process of customer designing to save costs |

9 . Customers can use PAYPAL and other online payment platform to pay a small amount of sample fee to shorten the sample production time |

10 . A variety of online tools (Skype, MSN, Trademanager ...), telephone, and e-mail can be accept |

11 . For some parts which need open a mould but not sure design,we are able to provide hand work samples for testing before open a mould |

12 . We can provide processes for some special materials, such as titanium, molybdenum, tungsten alloy and so on. |

13 . Provide valuable pictures anytime |

14 . Our company has 13-year manufacturing and solutions experiences |

- - - -

?

Company Information:

?

? ? ? Our primary products are engineering components for all kinds of industries. So far, JTH Metals provides our customers several processes like casting, forging, stamping and powder metallurgy. We are serving Valve industry, Pumping industry, Fire protection equipment, Automobile industry, GET(Ground engagement tools), Agricultural machinery and General industries.

? ? ? ?We JTH Metals have strong quality assurance team, we have 5 quality engineers who do quality control for all shipments leaving JTH. We have in house equipment like spectrometer, CMM, hardness tester, roughness tester, thickness tester, Ultra-sonic machine, magnetic machine?projection machine and other inspection tools.?

?

Our Services:

?

1 . OEM service:

No agents, no trading company, reduce all unnecessary cost for you. Direct communication with our engineer.

2 . Professional team:

Over 10years custom fabrication manufacturer.Almost 40% high educated people.

3 . Globally acceptabe quality:

The products offered by us are 100% inspection by our experienced professionals to ensure their durability, reliability and long service life.?

4 . SGS certification.

Fast delivery, good quality, competitive price and excellent service.

Jintaihua Precision Molds Co.,Ld

Address: China guangdong shenzhen baoan district, Shenzhen, Guangdong, China, 518000

Tel: 86-135-90287963

Shenzhen Jin Taihua metal products co., LTD. Was established in June 2000, is located in baoan shajing xinqiao furong industrial zone, convenient transportation and superior geographical environment, is a professional engaged in precision metal mold design and production, metal stamping products, accessories, all kinds of oven door buckle, locks and chassis cabinets manufacturing, precision machinery parts processing, non-standard equipment design and manufacture of professional manufacturers. Now has complete production with the CNC computer gongs, computer lathe, automatic lathe, CNC milling machine, surface grinding machine, shearing machine, bending machine, line cutting machine, 16 t - 100 t punching machines and other processing equipment more than 80, the company factory building area of more than 1800 square meters, more than 100 employees, including research and development and technical personnel for 3 people, quality management personnel 8 people, production and technical personnel account for five people. Insist on development, innovation, quality, service, good faith for the company development.