Stainless Steel Filter Element - SSFE01

Stainless Steel Filter Element For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Stainless Steel Filter Element, Made in China, High Quality Products!, China stainless steel filter element, filter element Supplier, Manufacturer.

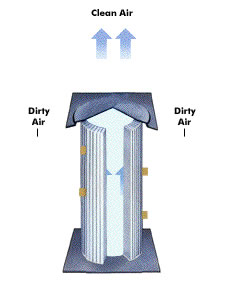

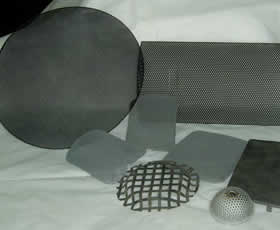

Stainless steel filter elements are made up of several layers of 316 mesh that are sintered together to form an integrated porous element. The middle mesh is of very fine gauge and determines the filtration efficiency of the elements. This layer is then overlaid with inner and outer layers of coarser mesh, to give support and protection.

The elements are a typical surface filter and the contaminants are retained on the surface of the filtration layer, this makes cleaning and back flushing a simple process. These filter elements should be ultrasonically cleaned to give best results.

Stainless steel filter elements are particularly useful in heavily contaminated applications and for use as pre-filters before disposable type final filters. Gaskets are required with stainless steel filter elements. The options are Viton, PTFE or high temperature annealed copper.

stainless steel wire cloth elements are idea for hostile or severe environments and applications. That is why clean ability is so important. All of our wire cloth stainless steel filter elements are easily restored back into service by back flushing, ultrasonic or other non-abrasive cleaning techniques. When used in filtration applications involving hazardous fluids, the clean ability of our stainless filter elements can significantly reduce disposal costs.

Anping Wingle Filter Element Factory

Address: 78 Jianan street, Anping, Hebei, China., Anping, Hebei, China, 053600

Tel: +86-318-38642227

Wingle manufactures the following types of filter elements:

Hydraulic, designed to equip pressurized filters, filter drain and other hydraulic systems.

Oil intended for lubricating systems, filters, complete machines and mechanisms in various industries.

Fuel intended for the complete fuel filters vehicle engines.

Aircraft designed for air filter assembly vehicle engines and compressors.

Filter elements are manufactured with a nominal fineness of filtration:

- Paper - 05,10,25 and 40 microns

- Net - 40, 80.120 and 160 microns

Filter elements provide the highest degree of filtration efficiency for industrial, mobile, and process applications. Our filter elements are composed of micro-glass media, the most recent innovation in high performance filtration technology. Micro-glass media is inert, inorganic, and far exceeds any paper or cellulose filter element performance. Water or chemicals, which cause softening, swelling, and degradation in conventional cellulose or pleated paper filters, do not affect micro-glass media.

The advantages of making filter element:

Filter elements and filters manufactured have a high technical specification through a number of structural and technological features, chief among them the use of modern materials quality, reliability and stability of the design process.

The use of modern filter materials:

Effective is the one filter element, which not only removes dirt but keeps them securely for the duration of the service. Depending on the material of the filter elements are divided into two main groups: surface and volume. use of filter material has been a very stable structure. Enhanced binding of the fibers provides a stable bond between the fibers and increases the strength of the material under the influence of load versus load fluctuations of pressure and flow rate, temperature and aging. With this filter elements maintain its high performance during its entire life.