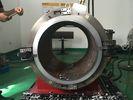

Split Frame Pneumatic Pipe Beveler , Pipe Cold Cutter For 3& quot;-8& quot; Working Range - AODP-230

Split Frame Pneumatic Pipe Beveler , Pipe Cold Cutter For 3& quot;-8& quot; Working Range For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Split Frame Pneumatic Pipe Beveler , Pipe Cold Cutter For 3& quot;-8& quot; Working Range, Made in China, High Quality Products!, China cheap prodocuts, china suppliers Supplier, Manufacturer.

?

Pipe Cutting and beveling Machine ?? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?

?

The series machine is ideal for all types of pipe cutting &?beveling and end preparation. The split frame design allows the machine to split in half at the frame and mount around the outside diameter of the in-line pipe or fitting?for strong, stable clamping. The equipment performs precision in-line cut or simultaneous cut/bevel, single point, counterbore and flange facing operations, as well as weld end preparation on open ended pipe, Working Range from 2” to 48” O.D.(DN50-1200), on most wall thicknesses and material.

?

?

?

- - - -

Features ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? |

- - - -

?

# # Cold Cutting & Beveling improve safety

# Cutting and Beveling at the same time

# Self-acting tools feed

# Minimal Axial and Radial clearance

# Light weight and Compact design

# Easy installation & Operation

# Pneumatic or Electric or Hydraulic driven

# Machining heavy-wall pipe from 2” up to 48”

?

?

?

- - - -

Application ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?? |

- - - -

?

# # Oil & Gas File

# Power & Chemical?Plant

# Nuclear Power Plant

# Process Plant & Fabrication

# Ship Building And?Repair

?

?

?

- - - -

Specification ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? |

- - - -

?

# # Drive Options: Pneumatic, Hydraulic, and Electric

# Air requirement: 1500L-3000L /Min@0.6/0.7Mpa

# Hydraulic requirement: 2-60L per minute 12.5Mpa

# Electric requirement:220-240V 1PH 50/60HZ

# Feed mode: Star wheel, automatically

# Feed rate: Fixed 0.08mm per circle

?

?

?

- - - -

Selection Guide ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?? |

- - - -

?

?

?

- - - -

Model | Working Range (OD) | d (mm) | D(mm) | L (mm) |

Inch | mm |

168 | 2”-6” | 50-168 | 185 | 512 | 178 |

230 | 3”-8” | 80-230 | 236 | 564 | 178 |

275 | 5”-10” | 125-275 | 283 | 612 | 178 |

325 | 6”-12” | 168-325 | 334 | 665 | 178 |

377 | 8”-14” | 219-377 | 386 | 719 | 178 |

426 | 10”-16” | 273-426 | 438 | 776 | 180 |

457 | 12”-18” | 300-457 | 469 | 807 | 180 |

508 | 14”-20” | 355-508 | 518 | 862 | 190 |

560 | 16”-22” | 400-560 | 570 | 910 | 190 |

610 | 18”-24” | 457-610 | 618 | 960 | 190 |

660 | 20”-26” | 508-660 | 670 | 1020 | 190 |

715 | 22”-28” | 550-715 | 719 | 1084 | 190 |

762 | 24”-30” | 600-762 | 770 | 1134 | 190 |

830 | 26”-32” | 660-813 | 830 | 1194 | 192 |

914 | 30”-36” | 762-914 | 924 | 1296 | 212 |

1066 | 36”-42” | 914-1066 | 1077 | 1468 | 212 |

1230 | 42”-48” | 1066-1230 | 1248 | 1646 | 212 |

- - - -

?

Suggest: size 1066 and above size select and use hydraulic type

?

?

?

- - - -

Order Guide ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?? |

- - - -

?

Before you place order to us, please let us know the following information:

# #

Choose suitable?Model

#

Confirm?electric power supply ( Voltage, frequency and phase)

#

Confirm the beveling angel needed

#

Confirm the welding joint required (U, V, Double V or Compound preparation)

#

Advise your pipe material ( Carbon steel, stainless steel or others)

#

Other special demands about machine

#

If the pipe wall thickness more than 30mm, inform us in advance (Important)

?

?

?

Working On Site ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ??

?

?

?

?

Customer Visiting? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?

?

?

?

?

After-Sale?Service ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ??

?

1. Warranty period: 12 months (Electric motor 6 months)

2. Emergency spare parts required dispatched within 24 hours

?

?

Nodha Industrial Technology Wuxi Co., Ltd

Address: ROOM 1203, BLOCK A, NO.58 LIANGQING ROAD, WUXI, CHINA, Wuxi, Jiangsu, China, 214000

Tel: 86-510-85808562

Rely on the quality and capacity, our equipments are well accepted in domestic and the world

market. We have experienced team concentrate on technology and research, which the base for our

growth and become stronger.