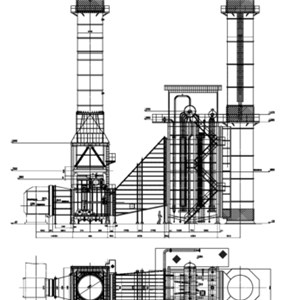

Sinter Cooler Waste Heat Recovery Boiler - No.1-1

Sinter Cooler Waste Heat Recovery Boiler For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Sinter Cooler Waste Heat Recovery Boiler, Made in China, High Quality Products!, China Sinter Cooler Waste Heat Recovery Boiler,Waste Heat Boiler, Supplier, Manufacturer.

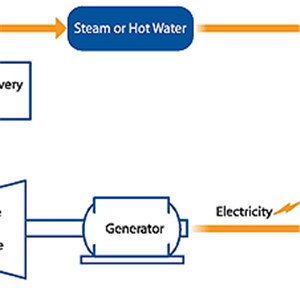

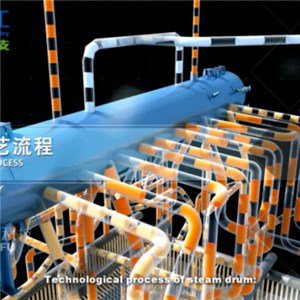

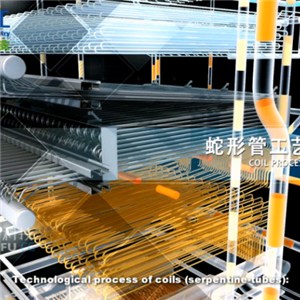

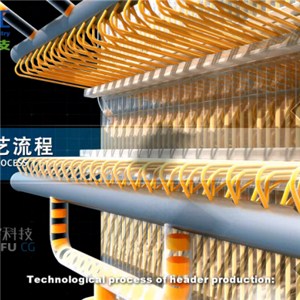

Sinter Cooler Waste Heat Recovery BoilerNecessitySinter Cooler process is highly energy consuming and it accounts for 10% of the entire energy input in steel making process. Moreover,Website:http://www.chinawasteheatboiler.com, 50% of the energy being consumed in this very process is lost in the environment in the form of emitting waste flue gas into our atmosphere. It is due to both equipment inefficiencies and thermodynamic limitations of the equipment. Recovering waste heat emanated from this process makes sense for both environmental sustainability and prospective economical benefits.?Design IngenuityOur boiler adopts inner thermal insulation pipe-box type structure to eliminate direct contact between flue gas and box steel frame. This structure not only ensures the safety of heat surface tube-box frame but also minimizes air leakage which is to lower heat loss & power consumption of induced draft fan, and increase overall operational efficiency. Heat surface adopts spiral finned tubes with high finned ratio & small diameter. This design enhances heat transfer and increases abrasion resistance. Also, all weld seam and elbow are located outside the gas passage which guarantees the long term safe operation of heat surface and provides convenience for maintenance. The average investment recovery period is only 1.8 years.Key Parameters?1 T Iron Ore = 120 KG ~ 150 KG of steam output ?HP pressure: 1.0 MPA ~ 2.5 MPAHP steam temp: saturated steam temp ~ 380℃LP steam pressure: 0.3 MPA ~ 0.8 MPALP steam temp: saturated steam temp ~ 260℃PROJECT SINTER COOLER 550 m2 WASTE HEAT RECOVERY FOR:?BAOSTEEL GROUP CO., LTD. - ZHANJIANG PLANTHP steam output: 65 T / H @ 1.8 MPA?HP steam temp: 360 Deg Celsius?LP steam output: 20 T / H @ 0.4 MPA?LP steam temp: 180 Deg Celsius (saturated temp)PROJECT SINTER COOLER 360 m2 WASTE HEAT RECOVERY FOR:JIANGSU SHAGANG CO., LTD. (SHA-STEEL)HP steam output: 45 T / H @ 1.57 MPA?HP steam temp: 320 Deg Celsius?LP steam output: 14 T / H @ 0.35 MPA?LP

Get QuoteJSDJ HEAVY INDUSTRY CO., LTD.

Address: No. 9 Huarui South Rd, Yancheng, China, 224005, Yancheng, Jiangsu, China, 224005

Tel: 86-0515-88583229

JSDJ Heavy Industry is a major supplier and EPC company of waste heat recovery boilers & systems for various industries,Website:http://www.chinawasteheatboiler.com, including steel-making, non-ferrous metal smelting, sulfuric acid, fertilizer, construction materials, and hazardous waste incineration.

As Asia鈥檚 leading force in the waste heat recovery sector, our overall integrity is ranked as one of the top three in China. As if 2016, over 30% of domestic waste heat recovery boilers came from us.

With business interests in and outside China, JSDJ plays an important role in helping the world reduce non-renewable energy consumption by installing our boiler systems for steam and power generation, all of which center around environmental sustainability.

JSDJ Heavy Industry is a major supplier and EPC company of waste heat recovery boilers & systems for various industries, including steel-making, non-ferrous metal smelting, sulfuric acid, fertilizer, construction materials, and hazardous waste incineration.

As Asia鈥檚 leading force in the waste heat recovery sector, our overall integrity is ranked as one of the top three in China. As if 2016, over 30% of domestic waste heat recovery boilers came from us.

With business interests in and outside China, JSDJ plays an important role in helping the world reduce non-renewable energy consumption by installing our boiler systems for steam and power generation, all of which center around environmental sustainability.

http://www.chinawasteheatboiler.com