Shot Blasting Machine HP8016 For The Surface Cleaning And Intensifying Of H Beam. - HP8016

Shot Blasting Machine HP8016 For The Surface Cleaning And Intensifying Of H Beam. For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Shot Blasting Machine HP8016 For The Surface Cleaning And Intensifying Of H Beam., Made in China, High Quality Products!, China cheap prodocuts, china suppliers Supplier, Manufacturer.

Shot Blasting Machine HP8016 For The Surface Cleaning And Intensifying Of H Beam.

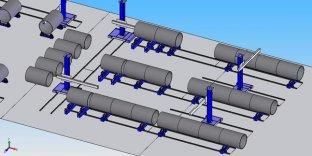

? shot blasting machine is specially designed for the surface cleaning and intensifying of H beam.

?HP 8016shot-blasting machine

Major technical parameter

- - - -

Work-piece size | Cross section (width × height) | ?800×1600mm |

Length of the wore piece | 3500-16000mm ? |

Quality standard | Surface cleanness | Sa2-Sa2.5 |

roughness | 15-50um |

Production rate passing speed of the work piece | 400-2500mm/min |

impeller head | Type | Q034 |

Quantity | 8 |

Shot blasting capacity | 8×280Kg/min |

Power rate | 8×11KW |

Elevator | Lifting capacity | 120t/h |

Power rate | 7.5kw |

Longitudinal spiral conveyer | Conveying capacity | 120t/h |

Power rate | 7.5kw |

separator | Separating capacity | 120t/h |

Ball-clearing system | Power rate | 11kw |

Load-carrying capacity | 4293m3/h |

Input/output roller way | Capacity | 1000kg/m |

Power | 2×2.2kw |

Delivery speed | 400-4000mm/min |

Length of the roller | 13000mm×2 |

Dust removal system ? | Blowing rate | 16000 m3/h |

power | 15kw+3kw |

Total power | About 140kw |

? | ? | ? | ? | ? |

- - - -

Performance

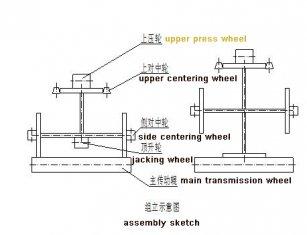

HP8016 H beam shot blasting machine is specially designed for the surface cleaning and intensifying of H beam. it can intensifying roughness and increase the adhesion effect. there are 8 shot-blasting device and anti-corrosion device on both sides of the blasting area. they will? be installed at the best piece according to the characteristics of H beam. there is a protecting cover lining on the internal wall of the box. which is replace. the dust-removing system adopts the internationally advanced drum-type device , characterized by high efficient , low running resistance, small volume and light weight .the dust emission meets the relevant requirements of the country regarding environmental protection.

Provide goods bound and compose parts

Impeller blasting: include clean room noumenon, portrait screw conveyer , eight Q034abrasive impeller, abrasion proof scale board ,

Ball track? system :include front and back ball track 26 meters, electromotor reducer, steel sheet piling circulatory system: include landscape orientation screw conveyer, bucket elevator, segregator , storage box , offer steel sheet piling.

Clean steel sheet piling setting: include conduit of dust removal, accommodate air valve, pulse filtering cartridge dust catcher and centrifugal blower.

Electric control system: include electric control cabinet , inward alternating current converter , junction box and? distribution box without protectors .

Inverter : Siemens ?Contactor: Siemens Electrical system: Siemens?

Technique document (send out to clientele after bargain go into effect )

a, Complete machine operation instruction(include electric

schematic diagram)

b, Transducer operation instruction , impeller blasting machine instruction

c. Commercial invoice

d. Equipment complete machine certificate of approval

e. Technique document

?

Wuxi Friendship Machinery Co., Ltd

Address: ROOM 722 ,MACHINERY BUILDING 151# Fuxing Road, Wuxi, Jiangsu, China, 214000

Tel: 86-510-82234202

We, Friendship Machinery Co., Ltd, As China leading expert in designing and manufacturing equipments for welding machine and cutting machine, automation system and metal works. We use and produce high-technology utilizing the most available mechanical and automatic techniques. Every work is uncompromisingly designed to improve our clients' competitiveness and productivity.

We continuously provide the most valuable automatic welding & cutting solutions to all around the world. Our modern manufacturing facilities utilize the latest high-tech production machinery, including plasma/flame cutting machine tools, auto welding stations, machining centres, and paints line. We care most of environment-friendly in the mean while of factory designing.

We apply proven experiences and innovative solutions to our products and services. We won a good reputation by our tremendous efforts and strategic adjustment in accordance with clients' real-time requirements.

Our main products: H&I beam welding line, T beam welding line, box column beam line, CNC multi-head plate cutting line, beam assembly machine, straightening equipment, steel pipe welding line, shot blasting machine, CNC flame/plasma cutting equipment, welding assisting machinery incl. Welding manipulator, welding positioner, turning roll (welding rotator), Membrane wall panel production line, which are widely used in many industries like aerospace, petrochemical, metallurgy, shipbuilding, chemical equipment, boiler pressure vessels, steel structure construction, etc.

Since 1990s, the market for steel structure building industry boomed. With fast development, very short period for construction and beautiful external appearance, as well reasonable price was occupied in the market of building industry.