screw jack table, worm gear screw jack systems - Depends on lift table sizes and loads

screw jack table, worm gear screw jack systems For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale screw jack table, worm gear screw jack systems, Made in China, High Quality Products!, China screw jack table, worm gear screw jack systems Supplier, Manufacturer.

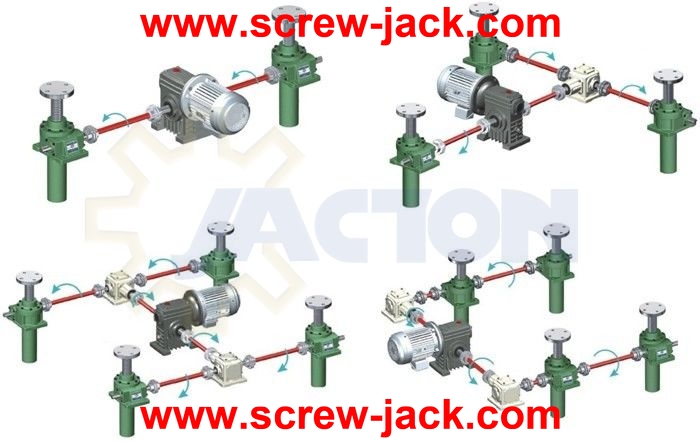

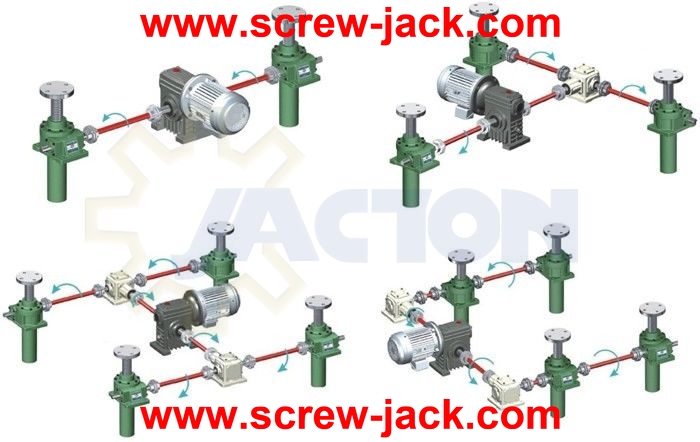

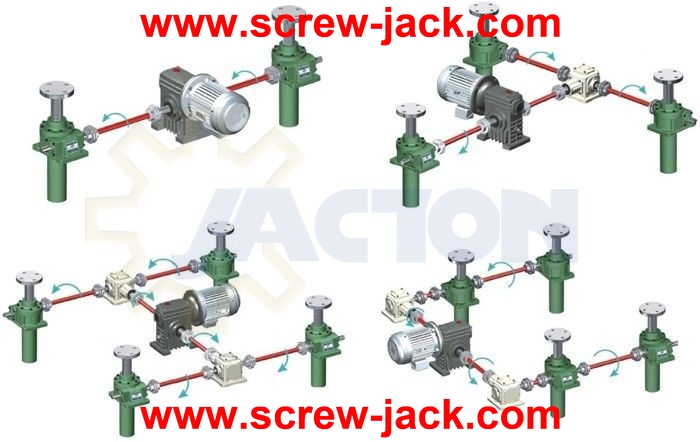

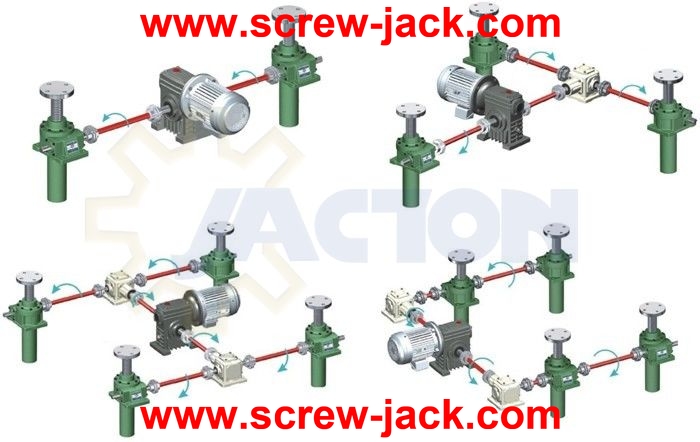

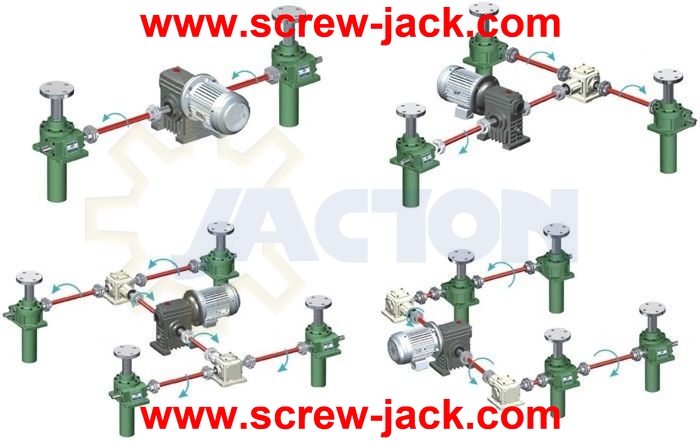

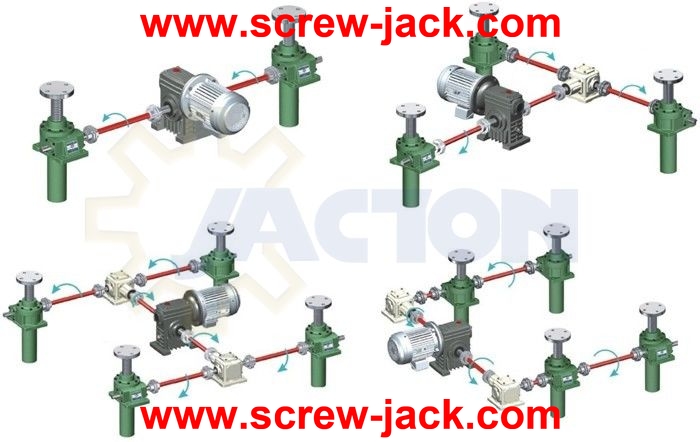

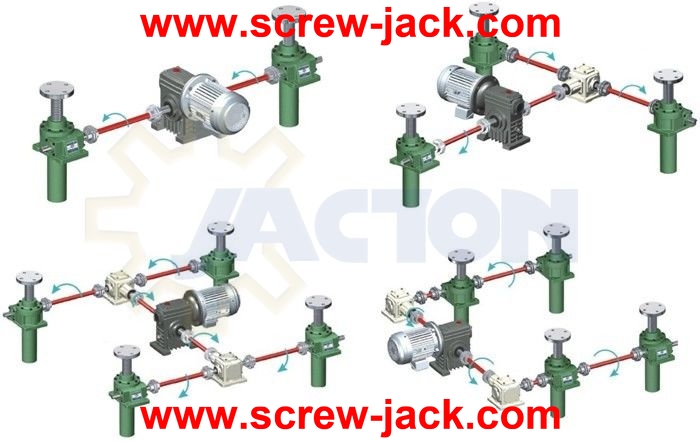

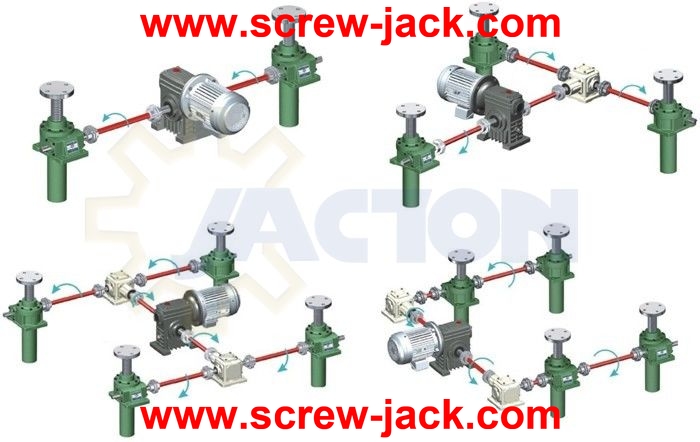

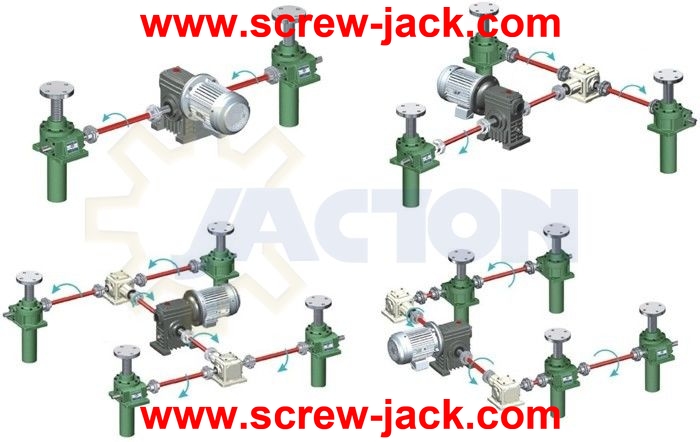

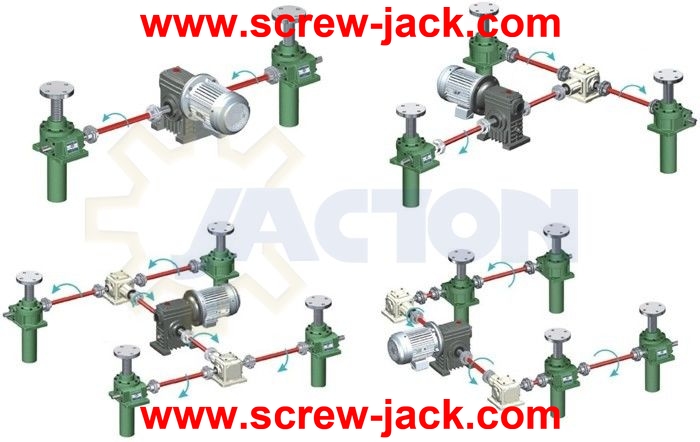

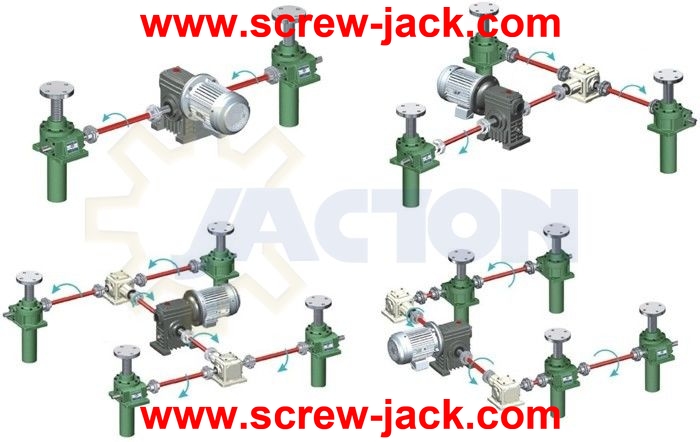

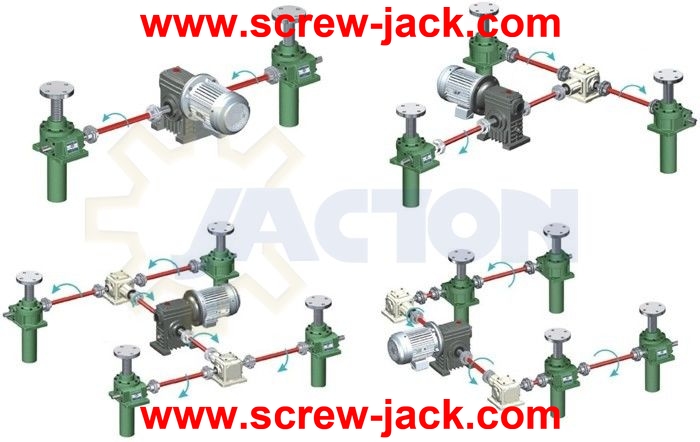

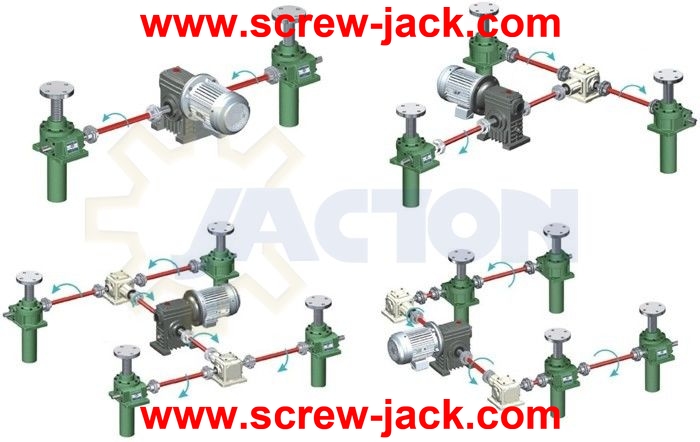

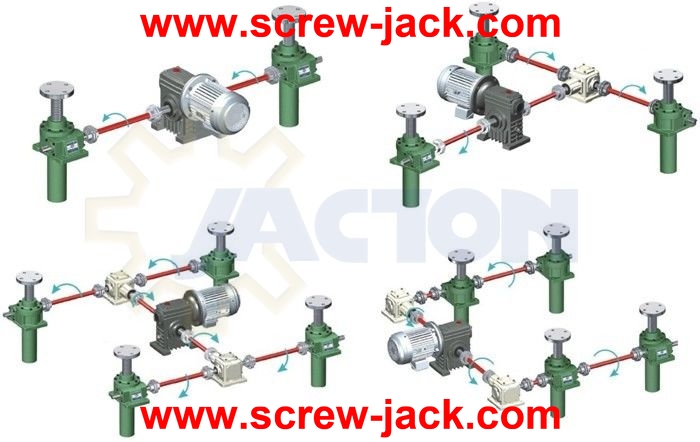

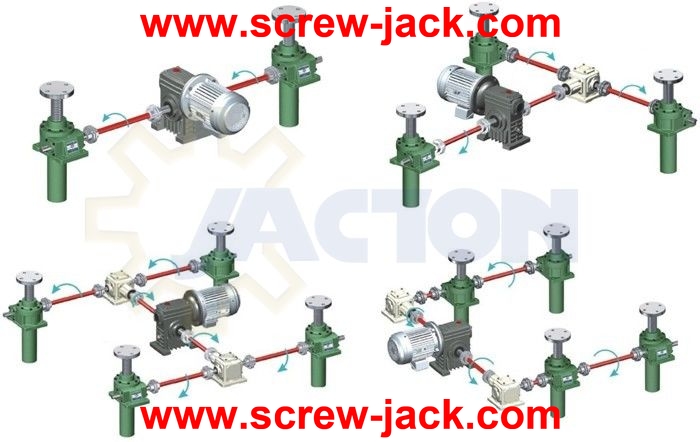

screw jack table, worm gear screw jack systems structures include bevel gearboxes, screw jacks, electric motor, gear reducer, hand wheel, pillow block bearing, jaw couplings and line shaftings. Compared to fast speed hydraulic lifting system and pneumatic lifting system, screw jack lift system is not only for the simple load-supporting from several kilograms to heavy duty several hundreds tons, but also have many advantages such as self-locking without brake or locking mechanism, precisely positioning, full synchronization, manual operated or electric motor driven, multiple screw jacks arrangments, easy installation and operation, maintenance free.

Efficiency

Two screw jack lift system, & quot;L& quot;, I and T configuration,, transmission efficiency 95%

Three screw jack lift system, I and T configuration, transmission efficiency 90%

Four screw jack lift system, H, U and T configuration, transmission efficiency 85%

Six screw jack lift system, 2H and U configuration, transmission efficiency 80%

Eight screw jack lift system, 2H and H configuration, transmission efficiency 80%

Notes: don& acute;t ignore bevel gearbox efficiency 98%

Application

Application in theatre stage lifts, sheet steel and steel pipes production lines, coil sheet slitter lines, paint coating lines, rewinding lines, pickling lines, cut to length lines, continuous hot dip galvanizing lines, spray infeed conveyor lift systems, wood working machines, plastics processing machines, textile machines, assembly equipment in the automobile and aircraft industries, food and beverage production equipments, packaging machines, adjusting synchronous coil feed lines rolls, feeder levelers and railway maintenance lifting platform.

Note: several independent motorized screw jack together constitute a screw jack lift system, considering full synchronization, if power source is three phase asynchronous motor, must be controlled with PLC (Programmable Logic Controller). Or use servo motor driven screw jacks.

Jacton Industry Co.,Ltd

Address: Building C, No.3078, Garden Road, Xin An Community, Chang An, Dongguan 523880, Guangdong, China, Dongguan, Guangdong, China, 523880

Tel: 86-769-81585810

Since 2000, Jacton Industry Co.,Ltd started to process worm and worm gear, acme thread screw and nut. Today, Jacton Industry Co.,Ltd follows a strict quality system, with senior engineers, experienced skilled workers and practiced sales teams, we consistently provides high precision, high quality and ideal lifting and positioning solutions with 鈥淛ACTON鈥?brand power transmission products such as trapezoidal screw type or ball screw type worm gear screw jacks with classic and cubic gearbox, spiral bevel gearboxes, screw jack lifting systems, lifting systems accessories, electric linear actuators, solar tracking actuators, bevel helical geared motor etc. We do more than only produce & sell 鈥淛ACTON鈥?brand power transmission products, we offer the support that you need to design and specify requirements.

Jacton Industry Co.,Ltd insists on choosing brand suppliers to supply the high quality raw materials to control the producing process. For raw materials of 鈥淛ACTON鈥?brand power transmission products, the suppliers must supply the raw materials quality testing reports, for example, the worm jacks & bevel gearboxes housing with chemical analysis report, worm jacks bronze worm gear & bronze nut with spectral analysis report, worm jacks & bevel gearboxes bearings analysis report following GB/T307.3-2005 standard, worm jacks trapezoidal screw or ball screw materials analysis report from the Iron & Steel Co.,Ltd certificate of quality etc.

鈥淛ACTON鈥?brand power transmission products are widely used in kinds of industries, up to now, Finished projects and Production lines include South Africa rail wagons projects, Mexico, Brazil and United States bolted tank lifting projects, Australia and France theater stage and orchestra pit lift platform projects, Russia, Australia and United States hydro projects or power station projects, the United Arab Emirates and Pakistan airport projects, Spain and Canada solar tracking projects, Malaysia and United States satellite dish projects.