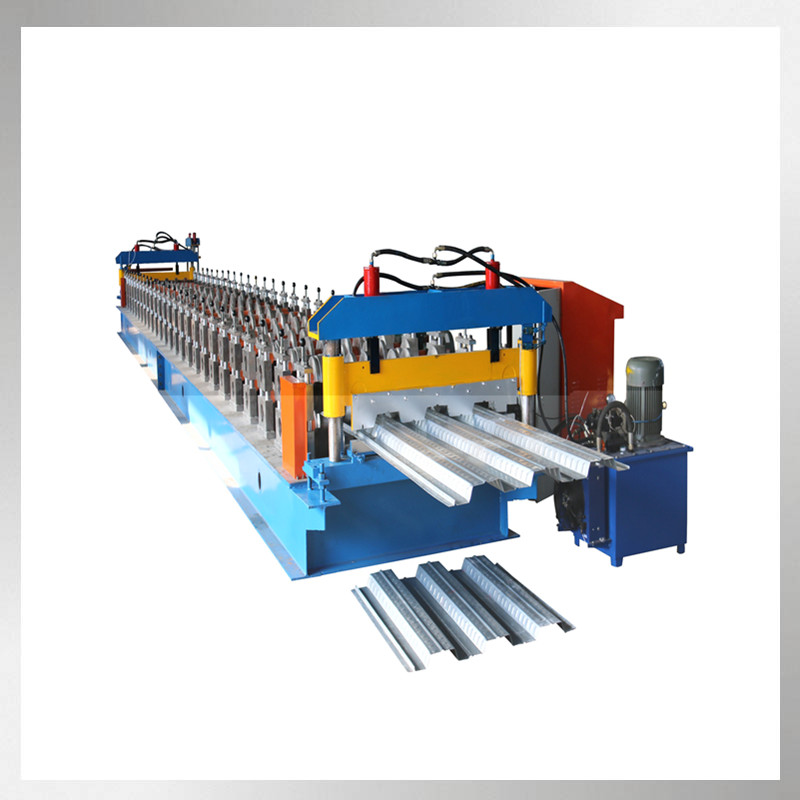

Scaffold catwalk panel/scaffold decking roll forming machine - cnzt-002

Scaffold catwalk panel/scaffold decking roll forming machine For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Scaffold catwalk panel/scaffold decking roll forming machine, Made in China, High Quality Products!, China Scaffold Decking Machine, Scaffold Catwalk Panel Machine Supplier, Manufacturer.

Scaffold catwalk panel/scaffold decking roll forming machine

Scaffolding, also

called scaffold or staging, is a temporary

structure used to support a work crew and materials to aid in the

construction, maintenance and repair of buildings, bridges and

all other man made structures. Scaffolding is also used in adapted forms for

formwork and shoring, grandstand seating, concert stages, access/viewing

towers, exhibition stands, ski ramps, half pipes and art projects (quotoed from

wiki). Now the metal ladder scaffolding for concrete slab and masonry

construction, here are some drawing profile and finsihed product pictures for

your reference:

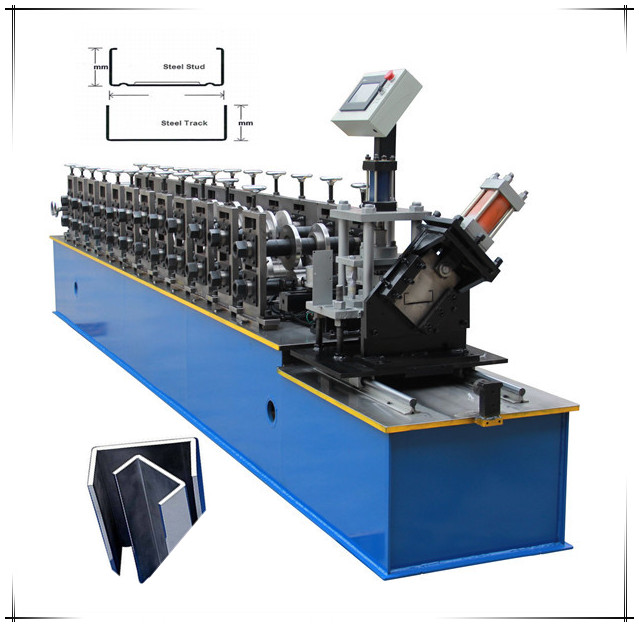

Advantage of our Galvanized layer ringlock scaffolding roll forming machine:

1. Rollforming Mills For Scaffolding Springboards is controlled by PLC control system ,during normal work,it will more security.

2. The basic of Scaffolding Board Making Machine is middle plate,it will be welded and tempering to avoid the distortion.

3.The frame of machine is iron structure,it will tempering.After this process, it will more strong and long life.

4.Transmission structure for the gear box. Each rack has a gear box molding can ensure that equipment over time, high-intensity running, and long service life.

Scaffolding roll forming machine

parameters:

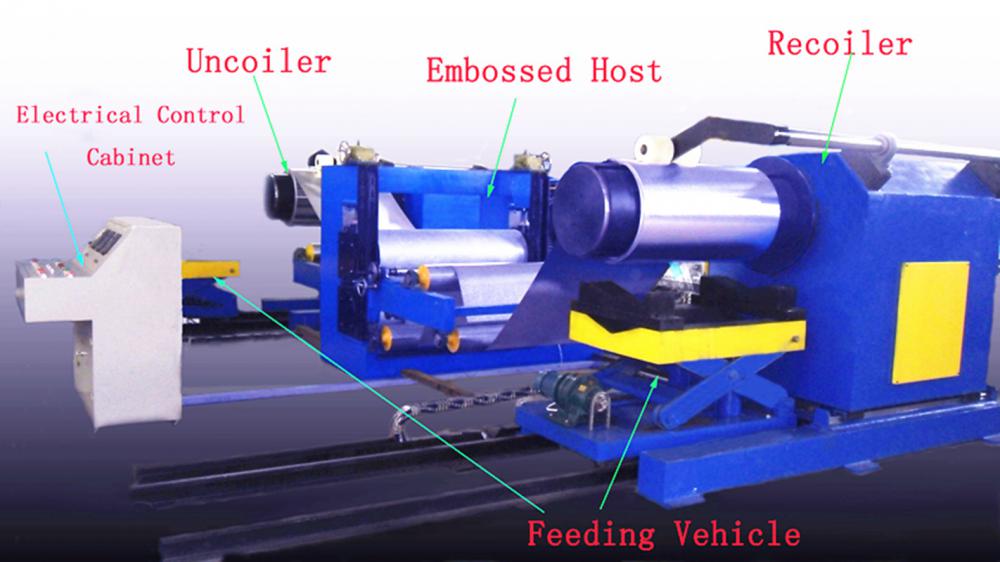

Machine

working process:

Decoile--> leveling--> servo coil feeding--> punching system--> roll forming machine--> sizing and

shearing

Systemà runout table

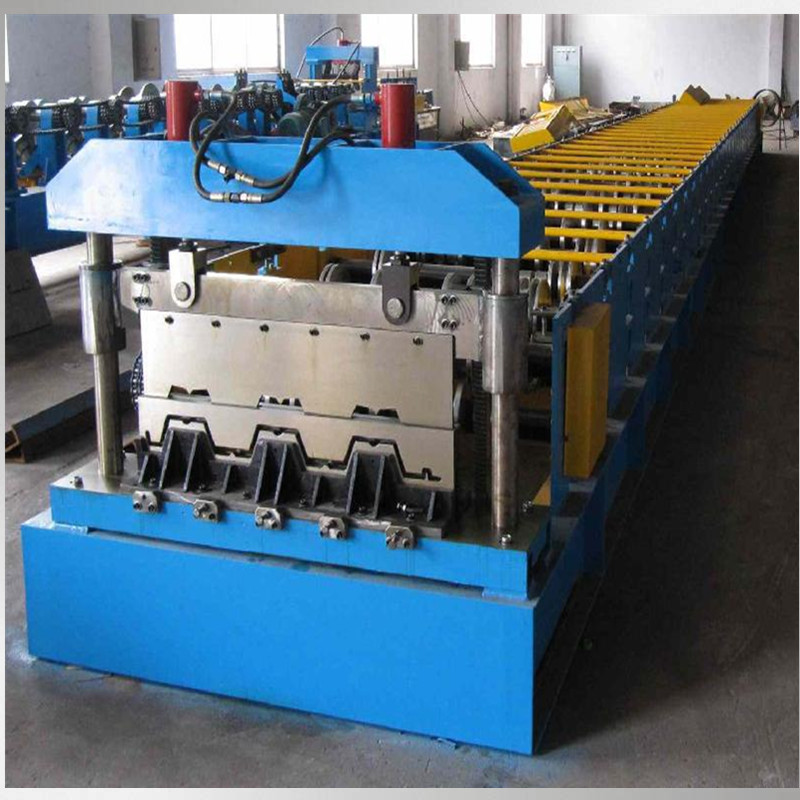

Main

roll forming machine

1.

Roller station: 18

2. Machine frame: Independ stand

3. Support the Max coil width: 380mm

4.

Machine frame material: HT200 tempering

5. Lelveing roller: 70mm, material is 40Cr quencing.

6.

Transimission: gearbox

8.

Main machine power: 15kw ZQ500 reduction box and

velocity ration is 31.5

10.

Shaft diameter: 80mm, made by 40Cr quencing at 56

to 58 degree.

11.

Roller material: GCr12, quenching to the whole and

make the hardness to HRC56-62o

12. Motor

explosive-proof grade: ExdIICT4

13. Motor

protection grade: IP54

Cangzhou Zhongtuo cold bending forming equipment manufacturing co., LTD

Address: Room 807, Building 6, Taida International,Yunhe district, Cangzhou City, Hebei province, China , Cangzhou, Hebei, China,

Tel: 0086-317-2191158

Cangzhou Zhongtuo cold bending forming equipment manufacturing co., LTD from 1996. We are specialized in manufacturing color steel forming machine,light keel machine,C&Z purlin machine,Glazed tile forming machine,welded tube mill, stone coated roof production line,steel structural floor panel roll forming machine and so on. We also have the derivatives and raw material. We real provide you one station, non-stop service,Now,our machine have been exported to 30 countries,such as Canada,South Korea,Russia,Holland,Sri Lanka,Malaysia,India,Brazil,etc.Our company insists on the service aim: Quality First,Credit First. We believe that we can make the future cooperation and achieve win-win.

http://www.rollsformingmachines.com

http://www.rollsformingmachines.com