Reaction Injection Molding - No.1-1

Reaction Injection Molding For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Reaction Injection Molding, Made in China, High Quality Products!, China reaction injection molding, China, manufacturers, suppliers, factory, company, brands, wholesale, buy, cheap, discount, low price, newest, best, high-quality, products, Supplier, Manufacturer.

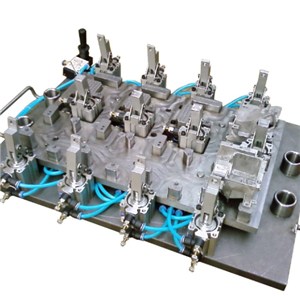

? ? ? ? Youde Prototype Co.,Ltd is a professional reaction injection molding company and we are also one of the best China reaction injection molding manufacturers and suppliers with one of the famous brands, our factory is able to produce newest and best reaction injection molding with high quality. Welcome to buy cheap or wholesale discount products from us.What is RIMRIM is a new process way for producing large size and huge quantity products rapidly . RIM process is monomer or pre-polymer (PU materials) in liquid state with a certain proportion which measured by the metering pump mixing in mixing head of a mold . After the mixture be injected into the mold under a low pressure/room temperature environment , it will rapid response and cross-linking curing . After ten more minutes , it will be solidified , and then release it from the mold , that part is RIM product . This process can be simplified as: storage, measurement, hybrid ,mold filling and curing , demould and post-processing.The process of Reaction Injection Molding1) StorageTwo raw liquid material used in the RIM process were stored in two reservoir at certain temperatures, reservoir is commonly pressure vessel. In molding , stoste usually in 0.2 ~ 0.3 MPa low pressure in the reservoir, and circulating constantly in the reservoir, heat exchangers and mixing head. As for polyurethane, the average temperature of stoste is 20~40 ℃, the temperature control accuracy is ±1 ℃.2)MeasurementMeasurement will be finished by the metering pump , and requirements for measuring accuracy is at least be ± 1.5%, and the best control should at ± 1%.3) HybridIn RIM process , product quality is largely depend on the quality of mixture in the mixing head , so does the production capacity . The normal pressure is about 10 Mpa in order to get the better effect .4) Mold fallingThe characteristic of RIM process is the material flow rate is very high .Then stoste’s viscosity can not be very high .Such as the viscosity of polyuret

Get QuoteYoude Prototype

Address: No.16,Lane 8 Xinle village Xixiang street,Baoan District, Shenzhen, Guangdong, China 518105, ShenZhen, GuangDong, China, 518105

Tel: 86-754-8472576

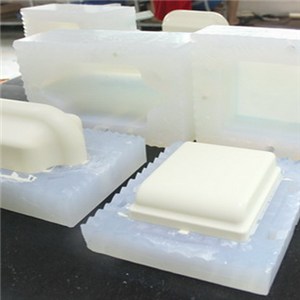

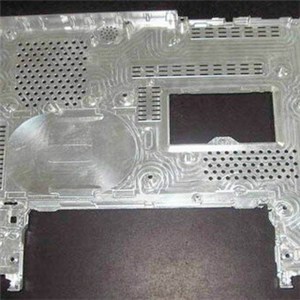

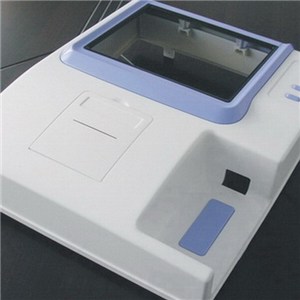

Youde Prototype limited is a professional rapid prototype and mold manufacturing company,Website:http://www.youdeprototypechina.com, we provide the one stop solution to global partner since 2005, from design,prototyping, mold and mass prodution,we offer a variety of comprehensive services, including CNC, Silicone Mold Vacuum Casting,SLS銆丼LA Laser, mold design and manufacturing, Stamping, Bending, injection. And we are professional in all kinds of metals and plastics rapid prototyping, small scale production, heat forming, mold design and manufacturing, as well as high precision machining.

Meanwhile, we have close cooperation with many excellent companies in our industry, so our team of professional specialists can provide you with efficient and reliable technical service and support.

After years of development, our clients are widely in many industries including medical, telecom,automotive, consumer, industrial and many other industries. They are mainly in China, the United States, Europe, East Africa and Southeast Asian.

If you are looking for a rapid prototype and small scale production, our company is your partner to deliver what you want to build today! We do strive to help you take every good idea to become prototypes.

http://www.youdeprototypechina.com