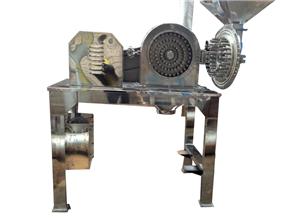

PVC Plastic Grinding Pulverizer Pulveriser Machine - No.1-1

PVC Plastic Grinding Pulverizer Pulveriser Machine For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale PVC Plastic Grinding Pulverizer Pulveriser Machine, Made in China, High Quality Products!, China PVC Plastic Grinding Pulverizer Pulveriser Machine,Mill Grinder Pulveriser Machine, Supplier, Manufacturer.

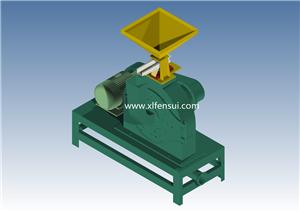

PVC plastic grinding pulverizer pulveriser machine?Product Descriptiona) the equipment should be firmly attached, pipe joints should seek to close to prevent gas leakage.b) Should be strictly checked before starting any loose joints, the rotation is flexible, direction of rotation is to meet the requirements, if unusual, should be excluded before boot.c) Require the crushed material should not contain metal, stone and other hard debris, if any, will cause serious damage.d) Put the boot should be preceded by the cooling water, particularly low melting point materials.e) Should be regularly checked the tension belt to prevent belt slippage.f) Should be strictly in accordance with the provisions of lubrication, general cycle for normal work week. If continuous rotation, 24-hour plus time.Product AdvantageThe machine features:1. Disc design, unique, with shear, impact, grinding, and other functions, uniform particle size, narrow distribution.2. Heat generated mainly by the high speed bearings, put the wind, the water cooling device so that the heat will not spread to smash the room. Indoor and crushed by the wind, the water of two cooling device, can the material in the heat generated during grinding away and the exchange of timely, so long crushed crushing chamber, heating small.3. The machine uses new strong narrow V belt drives. With the transmission power, smooth operation and high efficiency. And all are imported from Japan bearing assembly rigorous inspection of each part.4. Maintenance, operation and cleaning easy.5. Not with the network, crushed coarse and fine adjust, especially convenient and flexible.Working PrincipleAircraft from the body, frame, into the hopper, crushing equipment, a feeding pipe, gear and motor and other components, its internal structure shown in Figure 1: Matched by the host, fan, feeder sets, off air control, ESP , cabinet and vibration feeding machine and so the whole set of SFM plastic micro-grinding unit. Material from the feed tube

Get QuoteShengzhou Xinle Pulverizing Equipments Co, Ltd

Address: 38# Luozhong Road, Shanhu District, Shengzhou City, Shaoxing City, Zhejiang Province, China, Shaoxing, Zhejiang, China, 312400

Tel: 86-575-83136228

Established in 1998,Website:http://www.chinapulveriser.com, Shengzhou Xinle Pulverizing Equipments Co., Ltd (Xinle Company) is a manufacture of pulveriser, mill and grinder. Which are widely used in food & spice, chemical, medicine, rubber and plastic, graphite and etc. Especially our machine is quite suitable in sugar, garlic, onion, chili, ginger, LDPE, HDPE, PVC, tire rubber, etc. We start to export our machine since 2007. We have customers in India, Pakistan, Greece, UK, Syria, Spain, Vietnam, Bangladesh, Ghana, Ecuador, etc. More than 58% customers will reorder after they use our pulveriser. More than 30 workers with advanced equipments warmly welcome to visit our company!

http://www.chinapulveriser.com