Integrated Blood Collection Tube Production Line For Sale

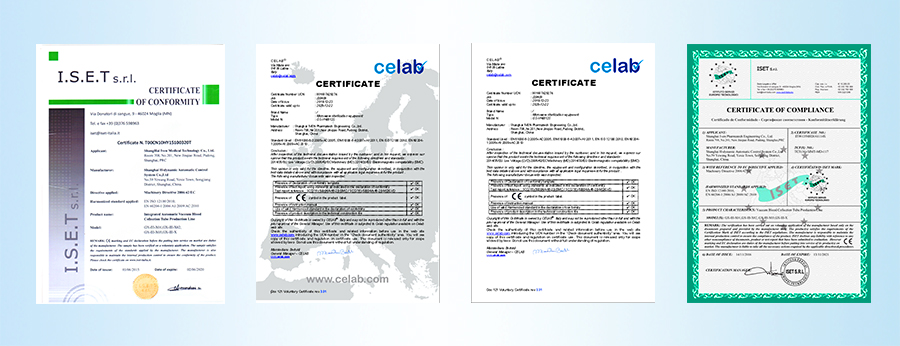

Post Time: 2017-08-03Integrated Blood Collection Tube Production Line For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Integrated Blood Collection Tube Production Line, Made in China, High Quality Products!, China Pharmaceutical Production Line, Integrated Blood Collection Tube Production Line, filling machine Supplier, Manufacturer.

Brief introduction & Advantage

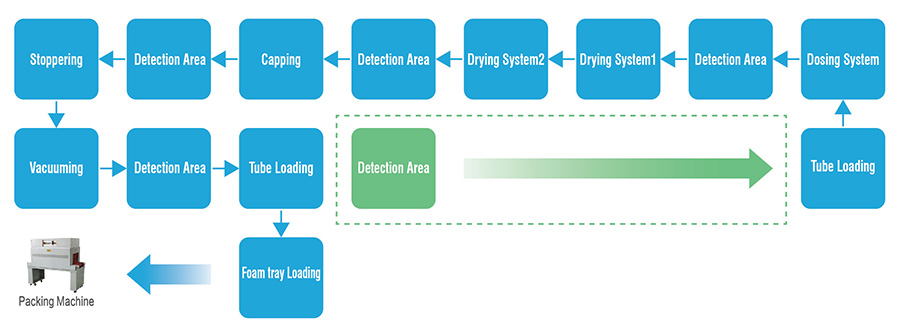

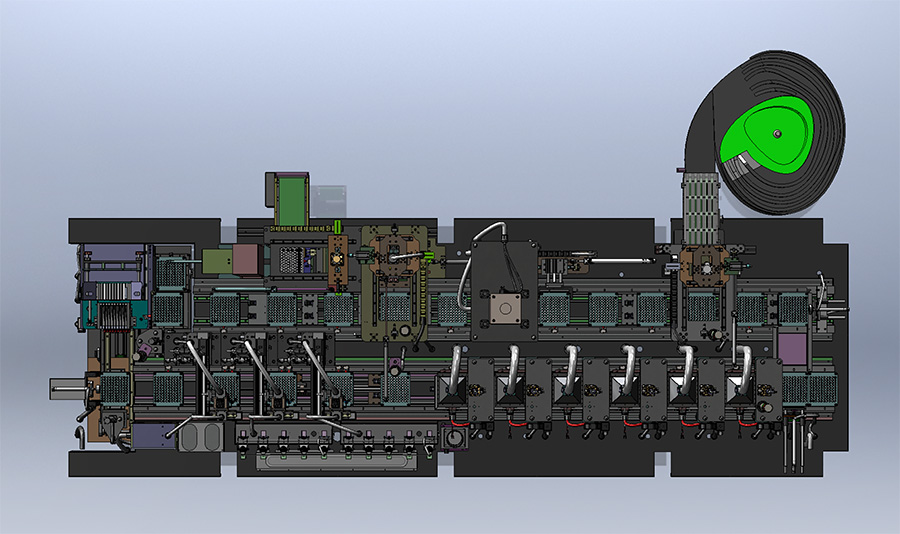

The whole production line equips with brand new online aseptic assembly and semi-finished product online inspection technology that achieve better stability, more accuracy and reliability so as to guarantee the machine keeps long term and high efficiency operation. The whole production line includes tube loading, atomization dosing, drying, stoppering & capping, vacuuming, tray loading, and etc. Easy & safe operation with individual PLC touch screen control, only need 2 workers can run the whole line well. Compared with other manufacturers, our equipment has unique features, including overall dimension is half smaller, higher automation & stability, lower fault rate and maintenance cost, and etc.

Production Procedures

Schematic Diagram

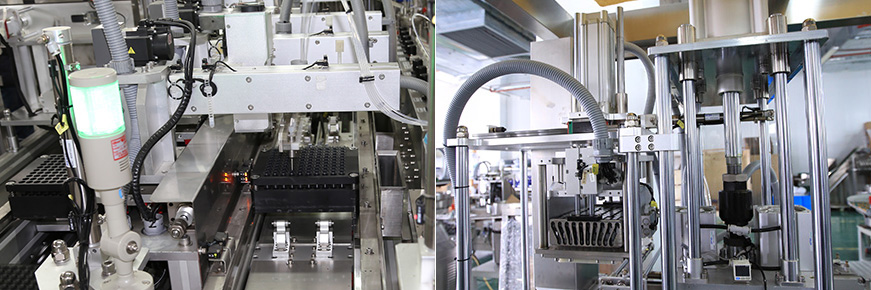

Tube loading: adopting with automatic tube loading technology, loading the tube into clamps automatically with detector for no tube or inverse direction tube. The machine apply for any kind of label tubes and solve the defect of the avo label broken of traditional tube loading machine from other manufacturers.

Atomization Dosing: The machine adopts with a set of 5 FMI precision ceramic metering pump and 1 set of five conjoined of micro - ceramic injection pump that can dose separately for biochemical tube and anticoagulant tube (EDTA salts, heparin salt); Another set of metering pump is dosing for sodium citrate tubes. Dosing volume controlled by PLC touch screen(see parameter), the error rate is ≦ 5%, and detect for no dosing tubes during the dosing process. Compared with other companies’ machine rely on stable air supply for dosing, our technology of dosing volume will not be influenced by any factors. 3 sets of dosing system meet all kinds of blood collection tubes production, that is the exclusive and advanced technology in China.

Drying: Adopting with six sets of dust-free PTC heating dryer to make the inner of products with zero pollution so as to improve the drying effect and production efficiency. Compared with traditional heating method, our machine solves the problem of temperature instability and pollution.

online Stoppering & Capping: finish the combination of stopper & cap online quickly and efficiently (apply for both type: upward and downward), and avoid the nonuniform vacuum degree when dose the tubes after the combination of stopper and cap and it may cause the stopper not seal well against tube. Detect for cap and rubber stopper and avoid the possibility of no stopper or no cap.

Main technical parameters

| Tube size | Diameter 13mm (length 75mm or 100mm), diameter 16mm(length 100mm) |

| Production capacity | 12,000 ~ 18,000 pcs/hour |

| Stoppering & capping pass rate | ≥99% |

| Vacuuming stopper-cap pass rate | ≥99% |

| Power supply | 380V/50HZ |

| Power | 12KW |

| Air consumption: clean compressed air pressure | 0.6 ~ 0.8Mpa, clean compressed air consumption: 300 L/ min |

| Dimensions | 4.5*1.5*2.1m |

| Weight |

2.5T |

Tags: Pharmaceutical Production Line, Integrated Blood Collection Tube Production Line, filling machine

Get QuoteShanghai IVEN Pharmatech Engineering Co., Ltd

Address: NO.201, New Jinqiao Rd, Pudong, Shanghai, China,

Tel: +86-21-58716151

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets.

IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on:

*Pre-engineering consulting service

*Production process selection

*Equipment model selection and customization

*Installation and commissioning

*Validation of the equipment and process

*Production technology transferring

*Hard and soft documentation

*Training for skilled workers and so on.

based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.

Related Products

Brief introductionAdvantageThe whole production line equips with brand new online aseptic assembly and semi-finished product online inspection technology that a......

Main Features1. Bottle washing machine adopts new design, rough cleaning adopts the same direction for bottle input and output, saving operators and machine spa......

This unit is made up of CLQ Ultrasonic Vertical Washing Machine, RSM SterilizingDrying Machine and KGYX FillingSealing Machine.Can be equipped with Servo-motor ......

Brief IntroductionXGF PP Bottle LVP Wash-Fill-Seal Machine has three sections, ionic air washing or ionic air plus water washing, constant pressure filling, and......

FE Non-PVC soft bag IV solution production line is the latest production line with most advanced technology. It can automatically finish film feeding, printing,......