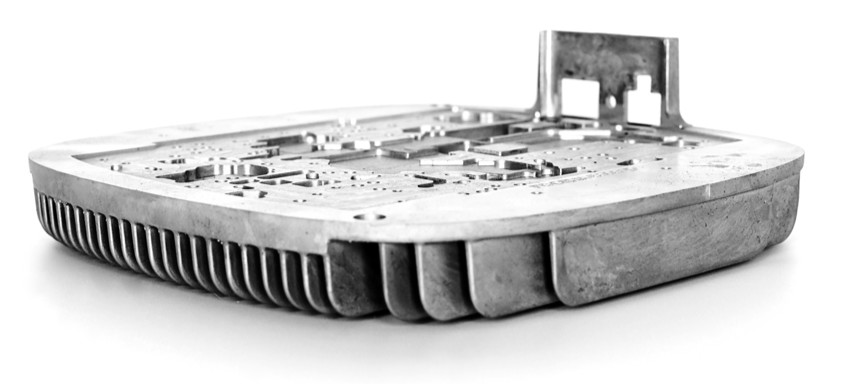

Die Cast Heat Sinks For Sale

Post Time: 2019-11-26Die Cast Heat Sinks For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Die Cast Heat Sinks, Made in China, High Quality Products!, China die cast heatsinks, die casting heatsinks,custom heatsinks Supplier, Manufacturer.

In the process to manufacture a die cast heatsink, two halves of a die are required in the die casting process. One half is called the “cover die half” and the other is called the “ejector die half”. A parting line is created on the part where the two die halves meet. The die is designed so that the finished casting will slide off the cover half of the die and remain in the ejector half as the die is opened. The ejector half contains ejector pins to push the casting out of the ejector die half. In order to prevent damage to the casting, an ejector pin plate accurately drives all of the pins out of the ejector die at the same time and with the same force. The ejector pin plate also retracts the pins after ejecting the casting to prepare for the next shot.

High Pressure Die Casting is a cost effective option for high volume solutions required to be light weight and superior cosmetic surface quality. Die Cast heat sinks come out in near net shape and require little to no additional assembly and can range in complexity. Die cast heat sinks are popular in the LED market due to the unique shape and weight requirements and high volume production needs.

We can provide companies, suppliers, and individuals with die cast heat sinks in a variety of applications, including:

Circuit boards (PC boards):

High powered lasers

Fixtures, housings & LED (light emitting diode) boards

Audio equipment

Automotive equipment

Communication equipment (such as cellular & satellite devices)

We’re also leading aluminum heat sink manufacturers for various types of communication equipment that is lightweight and offers excellent resistance against corrosion.

Any custom heatsinks services please feel free to contact pioneer Thermal :

Email: sales@ptheatsink.com

vivian@ptheatsink.comTags: die cast heatsinks, die casting heatsinks,custom heatsinks

Pioneer Thermal Technology Co., ltd

Address: Xiegang Village, Xiegang Town, Dongguan City, Guangdong Province, 523596, China,

Tel: 8615692434090

Pioneer Thermal Heatsink was established in 2003 in China with the goal of providing advanced thermal engineering and design services to customers. We specialize in the design and manufacturing of high quality, high performance but cost effective heatsinks manufacturer, which are widely used in the field of consumer electronics, Led, power, medical, telecommunications and automotive industries. We have a 75,000 square foot facility and certified with ISO9001 & 14001.

Our seasoned professionals can model and critique the thermal implications of your design using CFD, Solidworks, ProE, and AutoCAD. This enables us to create functional thermal solutions that meet the demanding cooling requirements in the most efficient and cost-effective way possible. We can manage your thermal needs from the conceptual design stage, through prototypes and into production.

Related Products

Aluminum extrusion heat sinks are an effective way to cool heat producing components in a cost-effective manner.Aluminum extrusion heat sinks can also be custom......

Process : Aluminum extrusion +stamping fin + heat pipes solderingMaterial :AL fin + AL extruded base+heat pipes.Heat pipes are a transport mechanism to move hea......

Skived Fin heat sinks can be an alternative to extruded heat sinks when looking for a fin density which can’t be achieved by extrusion technology. Skived heat ......

A custom stamped finheatsink is made from sheets of aluminum or copper, where the metal is stamped into a particular configuration based on the intended applica......

In the process to manufacture a die cast heatsink, two halves of a die are required in the die casting process. One half is called the “cover die half” and th......