8M3 Radio Frequency Machine RF Wood Kiln HFVD80-SA For Sale

Post Time: 2017-09-218M3 Radio Frequency Machine RF Wood Kiln HFVD80-SA For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale 8M3 Radio Frequency Machine RF Wood Kiln HFVD80-SA, Made in China, High Quality Products!, China RF Wood Kiln Supplier, Manufacturer.

Frequency Machine RF Wood Kiln are many times faster than traditional kiln dryers. The drying process can range from several hours for thiner, softer woods to several days for thicker, harder woods.

HFVD80-SA features an automatic feeder with a quick, automated drying cycle. It has a 50KW high frequency generator, 6 T hydraulic pressure and 8 m3 capacity. It is an ideal dryer for thick hard wood typically used in the furniture and flooring industry.

All models include high-tech Programmable Logic Controllers. The PLC comes with common hardwood presets ready for use. The PLC automates the drying process by starting the hydraulic pump, HF generator, vacuum pump and water system.

The water control system pulls the moisture to an external water tank which can then be drained. The weight system calculates change data to read the moisture content of the wood.

Our engineers can provide overseas installtion, training and are available to provide after-sell service and maintenance. We recommend proper training for sfe and prolonged use of the machinery.

Feature

*Fast drying cycle

*Automatic feeder

*Large capacity

*PLC automated systems with touch screen panel

*Uniform heating

*No sparking or bending problem

*Veneer, panels, softwood and hardwood planks, heavy timber with large dimension

*Patented weighing system, stainless steel cooling system

*Schneider, Omron, Siemens etc European spare parts

Basic Parameter of HFVD80-SA

| Overall Size | High frequency generator | 950*1050*1950mm |

| Tank | 9000*2160*2100mm | |

| Cooling system | 1500*1150*2000mm | |

| Gross Weight | 9 Ton | |

| Tank | Inside diameter | 1700mm |

| Stacking timber size | 1000*1000*8000mm (3.28feet *3.28 feet * 26.24 feet) | |

| Stacking timber capacity | 8 cubic meters | |

| HF Generator | Input power | 70 Kva |

| Output power | 50 KW | |

| Temperature Testing | Fiber optical temperature sensor | |

| Moisture Testing | Weighing system (PATENT) | |

| Cooling System | Stainless steel condenser with stainless steel water-ring vacuum pump | |

| Dewatering | Full automatic type | |

| Hydraulic Cyliners | 6 ton (4 pieces of stainless steel cylinders) | |

| Vacuum Pump | Material | Stainless steel |

| Power | 11 Kw | |

| Feeder Type | Automatic Feeder | |

| Tank Door | Ears Door (more safe and powerful) | |

| Weighing System | Weighing sensors under then tank (weighting wood everytime) | |

| Control System | Full-auto PLC touch screen | |

| Packing | 40" GP (5 packages) | |

Optional Models

| Model | HF Input Power | HF Output Power | Stacking Timber Size | Stacking Timber Capacity | Container |

| HFVD30-SA | 40 kva | 30 kw | 1*1*3 m | 3 m3 | 20" |

| HFVD45-SA | 40 kva | 30 kw | 1*1*4.5 m | 4.5 m3 | 40" |

| HFVD60-SA | 70 kva | 50 kw | 1*1*6 m | 6 m3 | 40" |

| HFVD100-SA | 70 kva | 50 kw | 1.3*1.3*6 m | 10 m3 | 40" |

| HFVD120-SA | 70 kva | 50 kw | 1.3*1.3*8 m | 13 m3 | 40" |

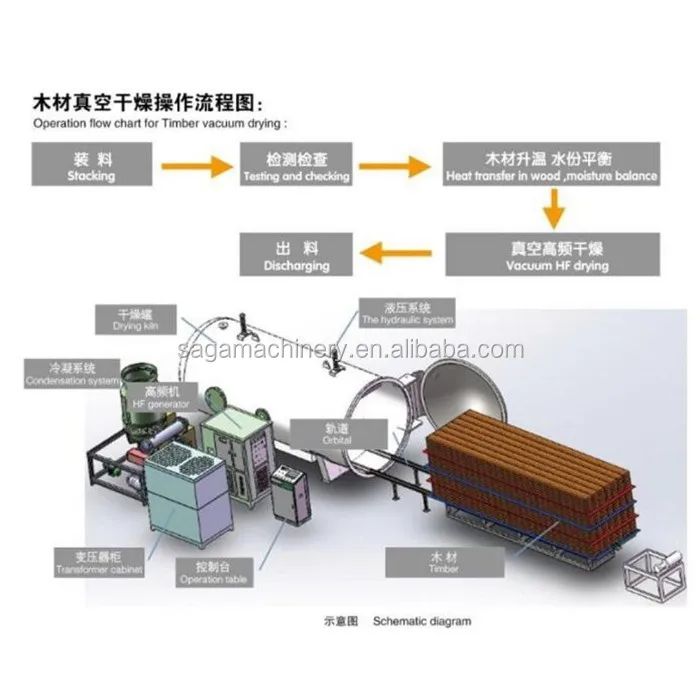

Main Parts of Saga Radio Frequency Machine RF Wood Kiln

1.High frequency generator

2.Control cabinet

3.Vacuum tank

4.Hydraulic system

5.Weighing system

6.Temperature tesing system

7.Cooling system

8.Full-auto feeder

Drying Cases

| Case | Drying Time | Drying Result | Consumption |

| Sliced veneer | about 40 hours | High quality on flatness and water content uniform | 200~250kw/cbm |

| Surface of floorboard | about 45 hours | High quality on flatness, no end cracking and deformation, no color change | about 200kw/cbm |

| Middle hardwood for second time drying | about 35 hours | Relieving tension, make water content uniform and make wood stable | about 150kw/cbm |

| Hardwood drying |

Rosewood: 7 days Red Sandalwood: 14 days |

No cracking or deformation, moisture content uniform, more stable | about 500~600kw/cbm,different consumption for different wood |

| Large plank | 7~10 days , moisture content from 60% to 20%,10cm thick+, like Birch,Larch,Pinus and Pine | No deformation on vertical direction, no cracking problem, more stable | different wood with different power consumption |

Tags: RF Wood Kiln

Shijiazhuang Saga Machinery Co., Ltd.

Address: GANJIANG ROAD OF SHIJIAZHUANG ECONOMIC AND TECHNOLOGY DEVELOPMENT ZONE,SHIJIAZHUANG CITY,,

Tel: 86-311-88394118

Saga Machinery Co., Ltd. is specialized in developing, designing and producing high frequency dielectric heating machinery. We are the main high frequency machinery manufacturer in China and have a professional know-how engineering group and a service group. Various needs from our customers can be met.There is a strict quality control system to ensure the quality of every product.

Our aim is to provide you with humanistic high frequency technology and service to help you improve the quality of your products and increase your production efficiency to the maximum.

Not only focus on the quality but also on the safety and convenience of users. Our humanistic design assures you of comfortably using the machine and experiencing the perfect industrial design.

The spare parts we use for the products are mostly European standard or brand or at least national top brand plus various protection systems both for human and machine. You can use it and feel at ease. The user-centered cautious designs ensure you that we can use it more freely.

Saga got its customer and user internationally like: South east Asia, Middle east, Africa, Eastern Europe and South America, we got service center at India and Turkey, we welcome specialized wood working company abroad for cooperation.

Our production cover with high frequency vacuum wood dryer, high frequency curved plywood press, high frequency edge gluer, high frequency precise frame assembly machine and high frequency generator.

Quality and Culture

TEST REPORT from Quality Supervision And Inspection Bureau

UTILITY MODEL PATENT CERTIFICATE for Full-automatic High Frequency Vacuum Wood Machine

Related Products

High Frequency Vacuum Kiln Dryer Wood Drying Kiln Sale are many times faster than traditional kiln dryers. The drying process can range from several hours for t......

Frequency Machine RF Wood Kiln are many times faster than traditional kiln dryers. The drying process can range from several hours for thiner, softer woods to s......

Frequency Machine RF Wood Kiln are many times faster than traditional kiln dryers. The drying process can range from several hours for thiner, softer woods to s......

High Frequency Vacuum Wood Dryer Heating Machine are many times faster than traditional kiln dryers. The drying process can range from several hours for thiner,......

High Frequency Heating Lumber Kiln For Drying Wood are many times faster than traditional kiln dryers. The drying process can range from several hours for thine......