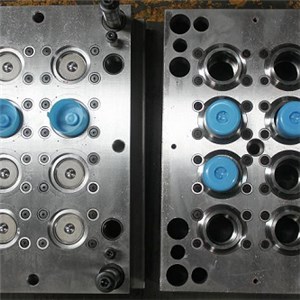

PET Jar Preform Mold - No.1-1

PET Jar Preform Mold For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale PET Jar Preform Mold, Made in China, High Quality Products!, China PET Jar Preform Mold,Preform Mold, Supplier, Manufacturer.

Features1.??Valve gate pin-valve gate ,pneumatic drive the nozzle pin?simultaneous high speed open and close action, which can effectively control the injection hole open and close actions on each cavity. Reliable seal function, smooth moving, low thermal expansion rate, long using life and also saves electric energy2.?Hot runner Hot runner system is designed and made by ourselves, it can achieve ideal and prompt heating effect for preform production, cavity with lower injection pressure to reduce wear and tear of mold?parts3.?heat system?With double heating system, it has separate temperature control mode ,the heat bar are used to heat hot-runner main?fold , small heaters supply the heating temperature for cavity nozzle continuously.4.?cooling system?Each parts including core ,cavity and valve gate has independently cooling system.5.?heat treatment Mechanical treatment cavity and core to prolong service life ,nitrogen treatment with neck screw. with fitly operation ,guarantee Long using life over 2.0 million times of injection cycle.Mold?DescriptionPneumatic,?pin-valve?gate,?shut-off,?free-cut,??PET?preform?mold?with?hot?runner.Cavity?quantities6 and?72?cavitiesMain?mold?baseP20?steel?(Nitrogen?treatment,?HRC?28-32?degree)Core?(punch)?and?cavityS136??(Vacuum?quench?treatment,?HRC?43-52?degree)Screw?neck?(lip)S136Heating?plateH13?steel?,?Chinese?standard?manifold.Heating?ringROTFIL?from?Italy.Temperature?controllerPID?voltage?temperature?controllerPreform?mold?configurationAdopted?European?moldstructure;?PET?materials?go?into?nozzle?tip?straightly?to?improve?mold?cycle?time.Cooling?system?on?cavity,?core.?If?you?require,we?also?design?the?cooling?system?on?neck?(slip).Preforms?drop?through?injection?machine?central?ejector?automaticallyThe?controller?heat?Individual?cavities,?runner?and?sprue.One?Temperature?zone?control?one?point?temperature.Double-locked,?inter-changeable?mold?components;Usage?life(guarantee)2,000,000?shotsWarranty?Period2?years

Get QuoteTaizhou Huangyan Sinco Plastics Machinery Factory

Address: No.626, Daqiao Road, Huangyan, Taizhou City, Zhejiang Province, China, Taizhou, Zhejiang, China, 318020

Tel: 86-576-84330528

With more than 10 years聽plastic machinery manufacring聽experiences,Website:http://www.sinco-machinery.com, located in Huangyan--"Blow Molding Machine聽City in China",聽sinco Machinery聽is the leading manufacturer of聽stretch blow moulding machines,聽extrusion blow moulding machines,聽injection molding machines聽and聽plastic injection moulds聽in China.. We are devoting ourselves to technical research in order to build up a good reputation & famous brand.

After decades' exertion and development, sinco has established a team of experienced designer and workers, a group of educated executive personnel. All of those factors permit that we are capable of having been developing different kinds ofplastic forming process聽and machinery to supply the best quality products and service to the customers. High quality but reasonable price has been widely approved by our customers both in home and abroad.

Focused on customers, cored on quality, the corporation and customers are viewed as a united whole. Customers' requirements are all we should do.After purchasing our products, our after-sale service relative to components, technical support, onsite service and operator training follows immediately if needed, no matter where you are.

http://www.sinco-machinery.com