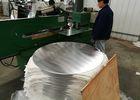

Personalized Flat 3000 Series Aluminum Disks Temper HO Anti Rusting Surface - Personalized Flat 3000

Personalized Flat 3000 Series Aluminum Disks Temper HO Anti Rusting Surface For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Personalized Flat 3000 Series Aluminum Disks Temper HO Anti Rusting Surface, Made in China, High Quality Products!, China cheap prodocuts, china suppliers Supplier, Manufacturer.

? Personalized Flat 3000 Series Aluminum Disks Temper HO Anti Rusting Surface

?

?

Quick Detal:

?

- - - -

PRODUCT | ALLOY | TEMPER | THICKNESS | MAX Diameter | Use |

ALUMINIUM Circle | 1*** ~ 8***Series | 0;H1-H112 | 0.1~6.0mm | 1500mm | Cookware Electrical Lighting Construction Others |

- - - -

?

Description:

?

The properties of aluminum circles (or shaped blanks) make them ideal for use in a number of markets including the cookware, automotive and lighting industries:

Low anisotropy, which facilitates deep drawing

Strong mechanical properties

High and homogeneous heat diffusion

Ability to be enameled, covered by PTFE (or others), anodized

?

Stick & non-stick,circle,disc Type and Non-alloy Alloy Or Not aluminum circle 1200 Made in china

Thickness range from 0.40mm to 4mm.

Diameter from 160mm to 1250mm

Alloy number 1060 ,1070,1100

Tmper: H24, H16 or H18.

Used to the process of stretching, spinning etc.

They can produce products such as kitchen utensils, electrical appliances, LED lighting shell.

?

1. Alloy type :

1050 1060 1070 3003 and Etc

?

2. Temper:

Soft, 1/2 Hard, 1/4 Hard, or Hard

?

3. Thickness Range:

0.35mm~5mm

?

4. Diameter Range:

120~1300mm

?

5. Surface Finish

Bright & smooth surface, without flow lines, slightly oiled to avoid White rusting.

?

?

Manufacturing of cookware Aluminium circle:

?

Decoiler → Accumulator→Tension Leveller →Acid&Alkali Cleaner → Rinse → Conversion Treatment → Priming coater →Infrared Curing Oven →Main coater → Floatation Curing Oven →Strippable Film Applicator → Exit Accumulator →Recoiler

?

?

Application of cookware Aluminium circle:

?

stock pots

fry pans

pressure cookware

bread makers

tea kettles

hollowware

lampshade

kitchen disc

cooking pan

?

Specification

?

- - - -

Product Name | Aluminum Circles for Deep Drawing and Spinning |

Hardness state | H14, H16, H18, H22,H24, H26, H22 ,H32,H34 and “O”. |

Product Size | Thickness: 0.30-8.0mm , Diameter: 20-1030mm |

Surface Treatment | mill finished, coated |

Processed | Deep drawings |

Min order quantity | 5 tons |

Application | Cookware, Electrical Appliances |

- - - -

?

?

Why choose us?

1. You could receive our reply within 24 hours:

2. We offer the best competitive price with high quality and good service for you;

3. The sample will be suppied for free

4. We have a team with rich experience and provide best sale-after for you.

5. Some quality certificates

6. Our products are popular at home and all over the world.

?

HENAN HOBE METAL MATERIALS CO.,LTD.

Address: No. 521-15, 5th Floor, Shili Building, Hongzhuan Road, Zhengzhou, Henan, China, 450000

Tel: 86-130-07527876

Hobe Aluminium is professional in manufacturing Aluminium Circle. Mainly producing Pure Aluminum Circle, like Alloy 1050, 1060, 1070, 1100 and Alloy Aluminium Circle, like Alloy 3003.

We are located in famous aluminium capital of Zhengzhou City, Henan Province. By using such kind of regional comparative advantage, we orient to provide the customers with high quality and substantial products at lowcost. Our Aluminium Circle is widely used in cookware, kitchenware, utensils, pot, kettle, non-stick pan, basin, bucket, frypan, tray, pressure cooker, traffic signs, furniture, lighting, lampshade, etc.

We would like to highlight our Aluminium Circle, with good physical performance, flat surface and smooth edge, Suitable for both deep drawing and Spinning.

We enjoy a good reputation among our customers for our aluminum circle with high quality and competitive price; win high appreciation from our clients with the excellent workman-ship and professional ability. The quality matches with ISO 9001 quality management system. We have 3 aluminium circles production line, and the annealing equipment.