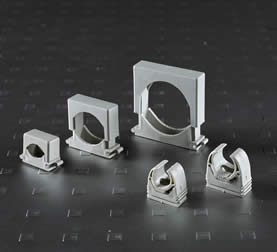

One-Way Clutch Bearing - 3DLHJ021

One-Way Clutch Bearing For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale One-Way Clutch Bearing , Made in China, High Quality Products!, China Castings, One Way Clutch Bearings Supplier, Manufacturer.

1.Professional low noise and no abnormal noise bearing technology make the noise level of the one-way clutch bearing reach the ZV4 level.So,they can substitute the same imported products.

2.Advanced forging technology makes the metal microcosmic crystal lattice of the clutch components more compact and rational.In addition,the surface quality is high ,the service life is long,the on-off operation is easy and the noise is further lowed.

3.Rational integrated design and machining technology ensures the high installment precision of one-way clutch bearing.Furthermore,the installment is easy.

4.The stalling torque is large and the freewheeling starting torque is small.So, the on-off operation is easy and the abrasion is less.

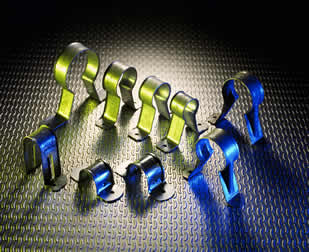

5.We can produce the CSK series one-way clutch bearings,such as CSK 12;CSK 15; CSK17;CSK20;CSK25;CSK30;CSK35 etc.The products with nonstandard dimension can also be ordered if the client need.

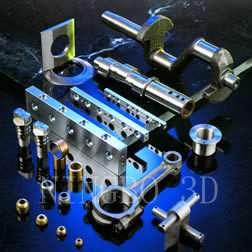

Ningbo 3-D Industries Co.,LTD

Address: No.75 Avenue 323, North Part of Huancheng West Road, HaiShu District, Ningbo, Zhejiang, China, 315016

Tel: 0086-574-87501891

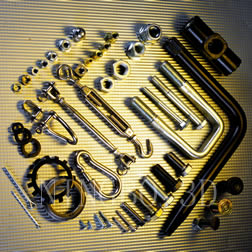

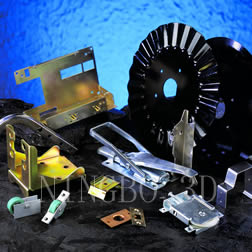

Ningbo 3D was founded in 1998, since then has always delivered various types of customs made machinery compoents to highly specialized world market, including automboile, agricultural machinery, food machinery, textile machinery, heating and cold systems inside vehicle, etc. As an ISO 9001 certified supplier, Ningbo 3D is a manufacturer that produce machining process in house , meanwhile also cooperate with a group of partnership factories for outsourcing castings, stampings, mouldings, hardware & springs, etc.

Quality is always the highest priority for Ningbo 3D. Unsurpassed attention to quality assurance is the key to Ningbo 3D's success. Many advanced equipments are used for production, ie. CNC lathes, digital display drilling and milling machines, bench drilling & grinding machines, machine center, ultrasonic wave cleaning machine, tapping machine etc, In the same time, several advanced test equipments are also used in the facility, ie. CMM and spectrometer. All these equipments along with a professional, experienced engineers and quality inspectors, is your assurance for quality products. From incoming materials to fininshed products inhouse, also all outsourcing products, several tests will be utilized to check the material properities, dimensions & tolerances , packing, in order to ensure that all final products conform full specifications from the customers ..