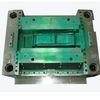

OEM HASCO /DME Plastic Injection Mould For Electronic Parts - KT12090163

OEM HASCO /DME Plastic Injection Mould For Electronic Parts For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale OEM HASCO /DME Plastic Injection Mould For Electronic Parts, Made in China, High Quality Products!, China cheap prodocuts, china suppliers Supplier, Manufacturer.

?

OEM HASCO /DME Plastic Injection Mould For Electronic Parts

?

Quick Detail:

?

Plastic Injection Molding part,electronic product

Model NO.:KT08920

Shaping Mode:Injection Mold

Packing:Standard Export Packing

Standard:RoHs, SGS

Production Capacity:500pcs/year

?

Description:

?

1) Mold design: Mold design according to your product drawing or sample.

2) Steel material: P20, 718, NAK80, S136, SKD11, 8407, 1.2363 or customers& acute; appointed material.

3) Mold type: Plastic mold, hot runner mold, double injection mold, insert mold, rubber mold, die casting mold, stamping mold.

4) Mold processing: Using advanced equipment for the molds, including digital control CNC (computer manufacturing center), EDM (electric-spark machine), several line cutting machines, multi-function milling machines etc

?

Applications:

The application of Injection Mould are in a broad range of industries,such us automotive,medical,electronic,

computer,office automation,mobile phone,EAS security ,industrial instrument ,and household appliances.

We accept all kinds of customized mould for each customer as per their requirements. The quotation can be made based on drawings or samples provided by the customers.

Our products are both excellent in quality and reasonable in price. Your satisfaction is guarantee.

?

Specifications:

?

- - - -

Mold steel | P20, H13, 718H, 2738, SKD61, NAK80, 8407, S136H, etc |

Plastic material | ABS, PC, PE, PP, HDPE, PPR, PVC, PBT, PS, PET, etc |

Mold base | LKM, HASCO, etc |

Mold runner | Cold runner and Hot runner, etc |

Mold Hot runner | DME, HASCO, YUDO, etc |

Mold cold runner | Point way, side way, follow way, direct gate way, etc |

Mold standard parts | DME, HASCO, etc |

Mold life | It mainly depends on various kinds of steel. |

Design software | Solid work, UG, PRO-E, CAD, etc |

Mold doff way | Doff plate, ejectors, air valves, hydraulic jar, etc |

Mold hot treatment | Including quencher, tempering, etc |

Mold cooling system | Water cooling or Beryllium bronze colling, etc |

Process | CNC milling center high speed, EDM machine (Taiwan), wire cut(Sodick) , etc |

Mold shipment | By Express,By sea, By air etc |

Mold packing | Standard Export Packing |

We will be the most reasonable price to you within 24 hours. |

Customers offer the 2D/3D drawing and the product requirements. |

Confirming the order (quality, price, material, delivery time, payment terms etc. ) |

According to client& acute; s requirement to prepare the production. |

Clients confirm the details of the Mold |

Surface shaping. |

Drill holes, high speed carve machine, wire cutting, EDM, etc. |

Arranging the test Mold and sending the samples to customers. |

Delivering by express, sea or by air, etc |

- - - -

?

?

Competitive Advantage:

?

1.Advanced technology with competitive price

2.Excellent mold designer team

3.High production capacity

4.Prompt delivery time

5.Perfect after-sales service

?

?

We can design according to customer requirements of different styles, patterns and colors of products

Strictly obeys the processing procedure according to customers& acute; requirement

Rich experience of cooperation with well known brand

Fashionable

Good communication with buyers& acute; R&D department for new products

Chuzhou KeTech Mould Co.,Ltd

Address: No.12 North LiXiang Industrial Park , Chuzhou, Jiangsu, China, 213000

Tel: 86-550-3950668

KeTech Mould.Your Solution Plastic Injection Mould and Plastic Products Partner

Founded in September 2010,Chuzhou KeTech Mould Co.,Ltd is a professional injection mould manufacturer, which is specialized in injection mould manufacturing,plastic products moulding and products assembly.

With main products refers to Automotive Interior,EAS Security and Industrial Instrument.

KeTech Mould supply customers in a broad range of industries such as automotive, medical, electronic, computer, office automation, mobile phone, and household appliances to name a few. 90% of our moulds and products are exported to North American, Western Europe, Asia, etc.

Our factory located in Chuzhou,Anhui China.Covers about 2000 square meters. With around 200 workers and four production lines, enabling us to meet your large OEM&ODM requirements. We conduct full QC process, from IQC to OQA, to ensure each unit complies with international standards such as CE.

KeTech Mould offers complete engineering services, from design concept, prototyping, tooling, production, through machining and metal finishing to complete assembly. KeTech Mould machining capabilities include zinc die casting, aluminum die casting, plastic injection molding, mould fabrication, Design service, sand casting, precision casting, Sheet Metal Fabrication, CNC Machining and Turning, Rapid prototype and Assembly.

If you require a solution Plastic Injection Mould and Plastic Products partner that works with you to produce the best possible products cost effectively and efficiently, contact KeTech right away for pricing information on your current project.

KeTech is an ISO certified, sole source supplier for all of your OEM&ODM related needs.