Nine plate automatic plate cut and brush machine APCBM-09 - APCBM-09

Nine plate automatic plate cut and brush machine APCBM-09 For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Nine plate automatic plate cut and brush machine APCBM-09 , Made in China, High Quality Products!, China battery plate cutting machine, plate cutting Supplier, Manufacturer.

Ⅰ.FEATURE

Fit for the plate size: with the plate ear width ≤380mm,without the plate ear X direction max size 330mm,Y direction max size 160mm,thickness:1.0-5.0mm,the buyer can supply the plate grid drawing.

1、The equipment adopts the main roller cut method, high precision cut, no waste.

2、Suction feeding, the cutter space can adjustable, the machine compatible with cutting nine plate, six plate, four plate.

3、 Special brush motor to ensure the safety of equipment.

4、Stainless steel rails, corrosion, will not affect the plate performance.

5、Automatic counting, plate fixed number of stack conveying, alarm double plate, cut pole ear, waste collection function and automatic transmission.

6、PLC control, high reliability, easy maintenance.

7、The X and Y conversion adopt the company& acute;s patented reverse mechanism, reversing the high speed and stable, fast cut speed, reach 60-100pcs / minute.

8、The whole working channel using local closure of patent, minimizing the recovery and lead slag, lead dust effectively, but also to better protect the machine less affected by the lead dust damage, extend the service life of the machine.

1, The device configuration,Control cabinet, the material feeding system, X roll cut system, t X roll cut system, power control system, brush head, cut head, the receiving plate system, the waste collection system.

2, The equipment configuration

(1) Control cabinet: 1pcs include PLC, text display, solid state relays.

(2) Feed material system: 1pcs include Rack, vacuum, power connection device, the sending device, sucker.

(3) X cut system: 1 pcs include channel steel, steel plate, stainless steel rails, brushing head, cut plate ear head, roller cutting head.

(4) Y cut system: 1 pcs include channel steel, steel plate, stainless steel rails, roller cutting head.

(5) Brush head: 2pcs Import brush wheel and brush motor

(6) Cut head: 6pcs the precision alloy blades, high-precision transmi

Shenzhen Chaosisi Technology co,.Ltd

Address: No.49 Changjiangpu Road,Henggang Street, Longgang District , Shenzhen, Guangdong, Chile, 518115

Tel: 8613682300523

Corporate Brief:

Shenzhen Chaosisi Technology Co., Ltd. was established in 1996, a pioneer R/D oriented equipment manufacturer, catering to the battery industries 鈥?covering both lead acid battery sector and lithium battery sector.

As a quality oriented manufacturer, CHAOSISI conducts its own in-house R/D under stringent product specifications; one of its corporate mission is to offer products with flexibility and durability often found on 鈥渋mported-grade鈥?equipment 鈥?and thus allow its product line to fill-in the blank among the domestic industries.

In the past years, Chaosisi has successfully achieved/earned 鈥渋ndependent intellectual property rights鈥? as well as holding dozens of 鈥減attern rights鈥?among its proprietary product lines, some of which are considered an INDUSTRY-FIRST in the field.

In present days, CHAOSISI products are reaching out to the world; its product foot print can be found in markets such as Southeast Asia, South America etc; it is expected the list will grow rapidly in the near future, and help to make 鈥淐HAOSISI鈥?a household word among the battery industries.

Chaosisi product lines are basically divided into three key categories:

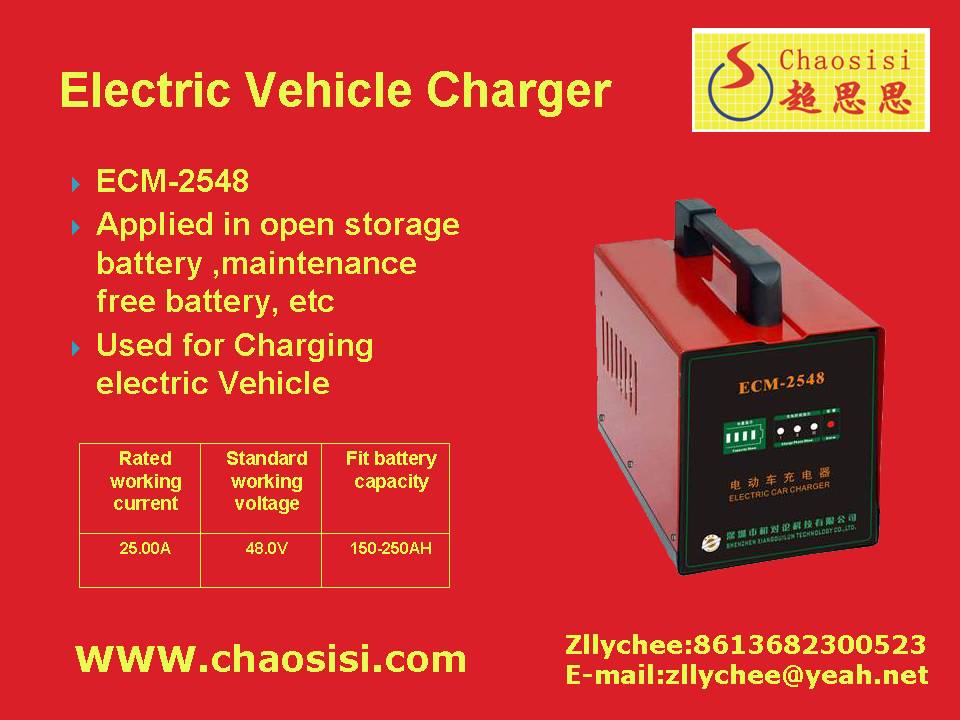

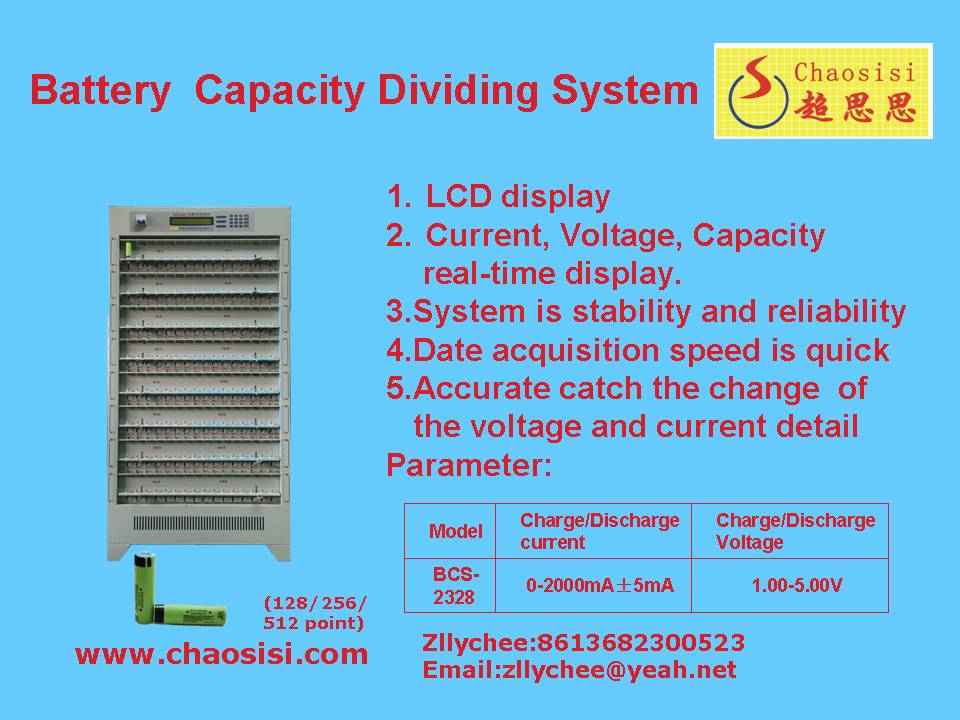

Lead Acid Battery Production System and Testing Equipment

Lithium Battery Production lines and Testing Equipment

Welding Equipment for both Metal and Non-Metal Applications

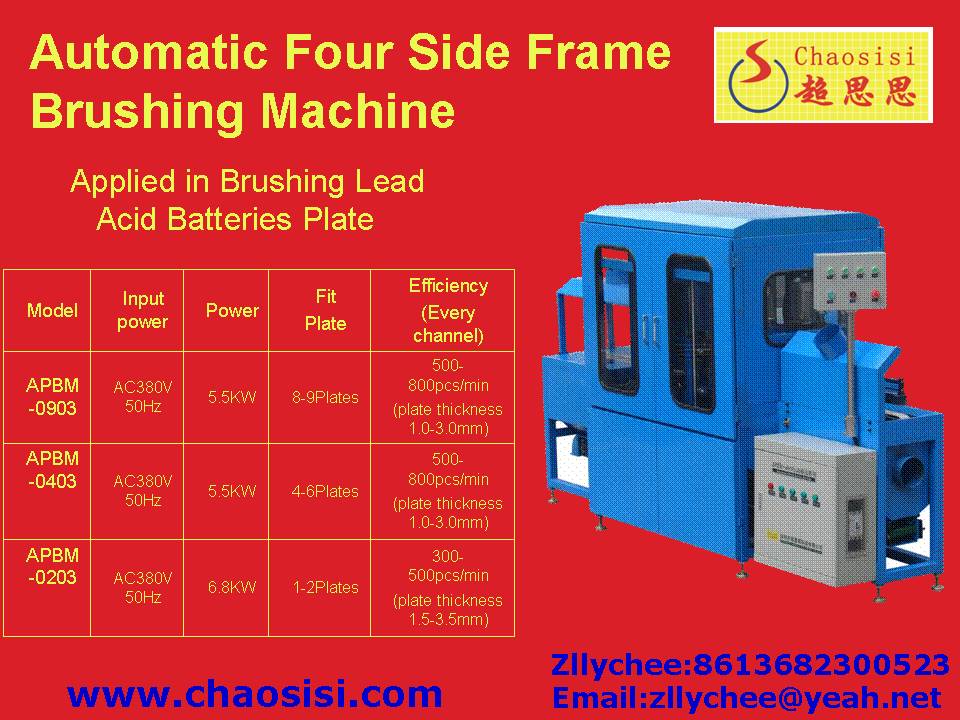

Presently, Chaosisi is launching two of its new products, namely-Automatic Multi-Plate Roll Cutting Machine 鈥?which offers twice the speed than what Can be found in the present market; Automatic Plate Brushing Machine 鈥?This well-packaged system utilizes a proprietary packaging scheme that offers dust-free operating environment.

In times to come, the company future product mix may invariably change in accordance with market demands, but 鈥淐LIENT SERVICE鈥?will remain as our COMPANY SPIRIT for times to come!