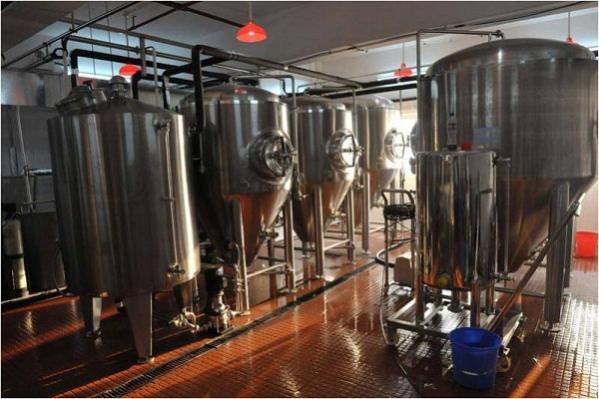

new condition CE/ISO CERTIFICATIONS MICOR BREWERY USED 10HL BREWING EQUIPMENT - 10HL

new condition CE/ISO CERTIFICATIONS MICOR BREWERY USED 10HL BREWING EQUIPMENT For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale new condition CE/ISO CERTIFICATIONS MICOR BREWERY USED 10HL BREWING EQUIPMENT, Made in China, High Quality Products!, China beer brewing machine, beer machine Supplier, Manufacturer.

Usages for all of the beer tanks

1-Malt Mill – Crushes the malted barley to the desired coarseness.

2-Hopper – Holds the entire grist (malt after milling).

3-Hot Liquor Tank – Used to

recover energy and heat the water (liquor) needed for sparging water onto the grain bed to convert starches to sugar.

4-Mash/Lauter Tun – Combines the grist and hot water. A false screen is then used to extract the clear wort from the malted barley.

5-Diverter Panel & Transfer PumpsTransfers liquid flow from the mash/lauter tun to the kettle and then on to the fermenters.

6-Brewkettle/Whirlpool – Boils the wort to a desired specific gravity

and hops are added for flavor and bitterness. The wort is then whirlpooled to collect soluable proteins (trub) in the center of the kettle. The clear wort is then pumped through the heat exchanger and into the fermenter.

7-Heat Exchanger – Using water and/or cold propylene glycol as cooling mediums the wort is cooled to an acceptable fermentation temperature before it goes into the fermenter.

8-Fermentation/Aging Vessel – The wort is pumped into vessel and added to the previously pitched yeast and allowed to ferment.

9-Filter (DE or Plate & Frame) – Used to filter all of the leftover yeast and sediment from the beer on its way to the serving/bright beer vessel. Beer does not always have to be filtered.

10-Glycol Reservoir/Cooler – Cold glycol is pumped from here to each cooled vessel to maintain and control beer temperatures.

11-Transfer Pump – Used to pump the beer from the fermenter to the serving/bright beer vessels.

12-Serving/Bright Beer Vessel – CO2 is added to beer through a carbonating stone to adjust the CO2 levels to the style of beer in the vessel. From this vessel the beer can be kegged, bottled or served via the draft lines.

13-CO2 Tank

Specifications of the vessels

1.Double wall sus304 structure design or with red copper epiboly for mash equipment

2.Surface treatment adopt welding polishing process or mirror polishing process

3.Vessel

Degong Equipment Technology Co.,Ltd

Address: China, Jinan, Shandong, China, 251600

Tel: 8658780867

DG company is one professional beer brewery equipment manufacturer in Shangdong,China.We own 1600m2 beer brewing equipment manufacturing plant.For many years producing,reaching,design experience accumulation,we not only have advanced technical equipment,but also have professional producing workers.DG strives to every details of equipments being the best and in the lead.We provide designing scheme and configuration scheme for buyers according to their requirements(output,standard,etc).We promise all the tanks inner adopt food grade stainless steel material,the epiboly can be red copper or stainless steel 304 according the the different usage.For example,if you use them in some place(restaurant,hotel,pub,bar,etc),you can choose red copper epiboly for its beautiful and attractive.In addition,our beer brewing equipment have obtained certifications of CE,ISO9001,etc.