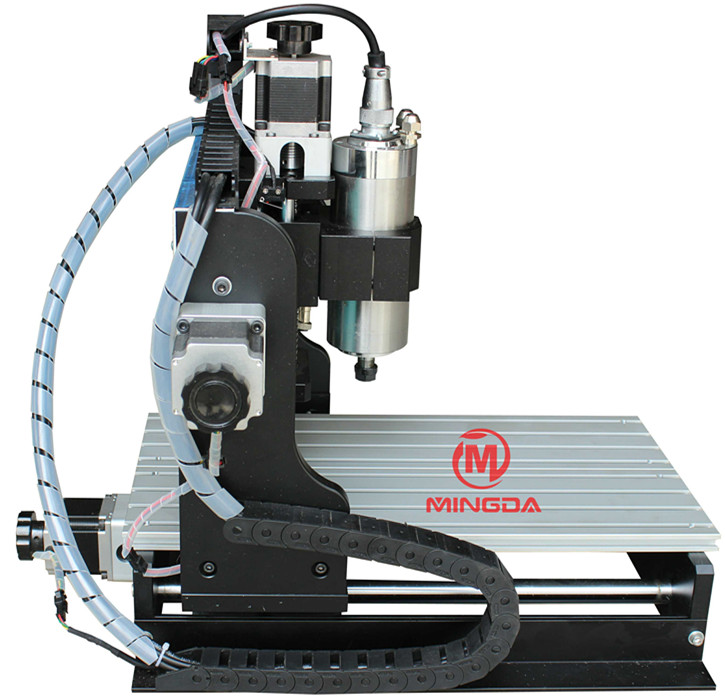

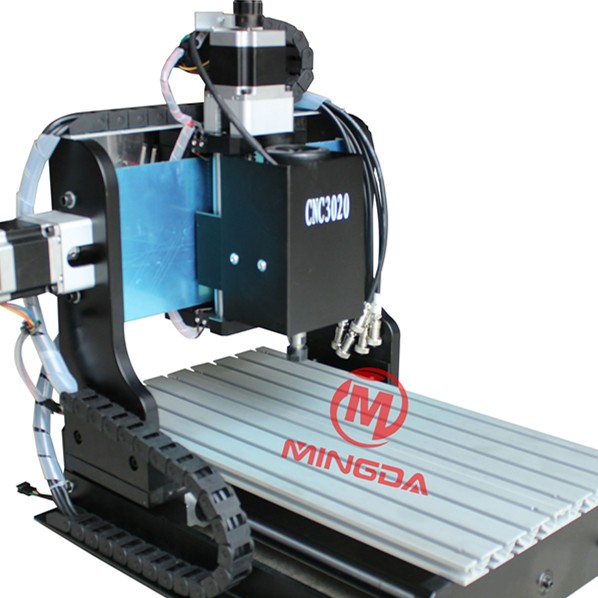

Mingda Manufacturer CNC 6040 1500W Woodworking Milling Carving Machine - CNC 6040

Mingda Manufacturer CNC 6040 1500W Woodworking Milling Carving Machine For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Mingda Manufacturer CNC 6040 1500W Woodworking Milling Carving Machine , Made in China, High Quality Products!, China CNC 6040 1500w, cnc 6040 1500w mingda Supplier, Manufacturer.

Specification

Model 6040

Dimension 900×690×520mm

Work area 840x480mm

X,Y,Z axis woking travel 400x600x80mm

The Max thickness of Carved objects 90mm

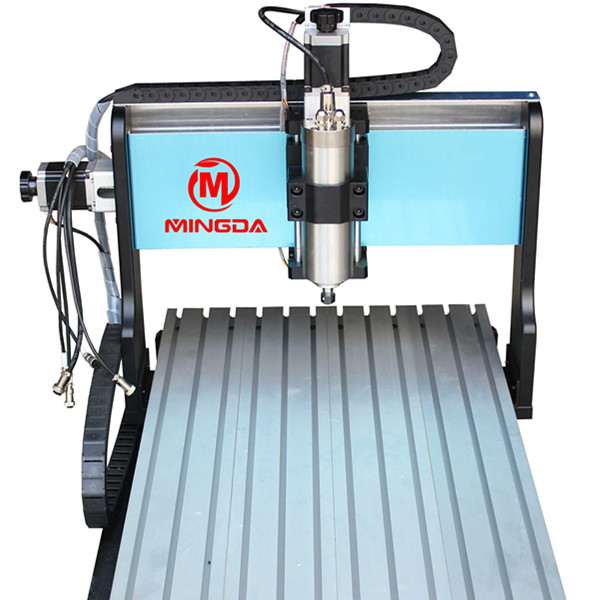

Rack material 6061Aluminum alloy

Transmission unit X ,Y,Z axis is 1605 T Screw

Sliding unit X:Φ20,Y:Φ16,Z:Φ13

water-cooled spindle

Frequency converter AC220V,1.5KW,0~400Hz(inside CNC controller)

Spindle Power 200W/AC220, SCM stepless speed regulation

Speed (r/pm) 0-8000

Clamping diameter 3.175mm

feeding speed max(mm/min) 3000

Carving speed(mm/min) 50~3000

Carving accuracy 0.03mm

Repositioning Accuracy (mm) 0.03mm

Input voltage 220V or 110V

Instruction format G code (tap, nc, ncc, text)

Compatible software Mach3/TYPE3/ArtCAM/CAD/CAM etc

Shenzhen Libwiet Technology Co., Ltd.

Address: 315, MinLe Technology Building, MinLe Industrial Zone, Meiban Road, LongHua District , shenzhen, Guangdong, China, 518131

Tel: 86-13500068891

Shenzhen Libwiet Technology Co., Ltd is a high technology enterprise which is specialized in the research, development, production and sales of 3D printer equipment and copy number machine. At the same time, our company also provides professional digital design and manufacturing solutions. We are committed to providing enterprises with integrated, rapid, accurate and true solutions. We firmly believe that the perfect drawing may be less physical intuitive. Our company ensures that rapid design brings greater profits and 3D printing promotes the design speed. Our goal is to realize the mass production of affordable home printer, which is convenient for designers, engineers, technical personnel and even ordinary lovers. Currently, we develop SLA 3D printer which is an additive manufacturing process which uses a vat of liquid ultraviolet curable photopolymer "resin" and an ultraviolet laser to build parts' layers at a time. It is 2014 now, and our new innovation will surprise the world!