Metal Floor Deck Roll Forming Machine - 13012

Metal Floor Deck Roll Forming Machine For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Metal Floor Deck Roll Forming Machine, Made in China, High Quality Products!, China Metal Floor Deck, roll forming machine Supplier, Manufacturer.

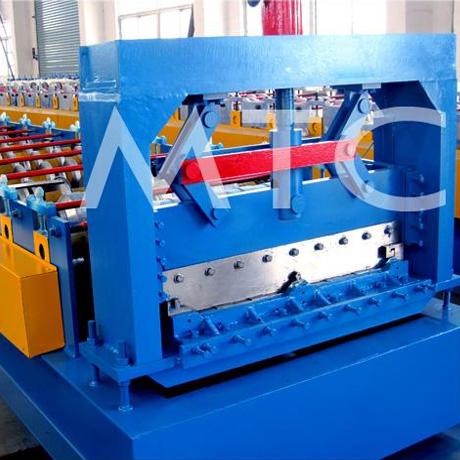

We are specialized in designing and building various steel floor decking roll forming machines,such as close-type steel floor deck roll forming machine,3-waves steel deck floor roll forming machine,2-waves with ribs steel floor deck roll forming machine etc. In modern time,people prefers to use steel instead of stone or cement for construction projects,such as the steel floor decks, because it is more convenient to fill the concrete into other steel floor deckings than to use the stone floor.

Product features

Technical Data for Main Parts on Steel Decking Floor Roll Forming Machine:

Uncoiler: Manual Uncoiler

Thickness of Material: 0.8mm—1.2mm

Effective Width:780mm

Coil Weight: 5 Tons

Coil OD:1500mm

Coil ID:508--610mm

Feeding Guide OF STEEL FLOOR DECKING ROLL FORMING MACHINE:

2 Rollers to guide the material into the machine

Both ends of the flat roll adopt bearing structure.

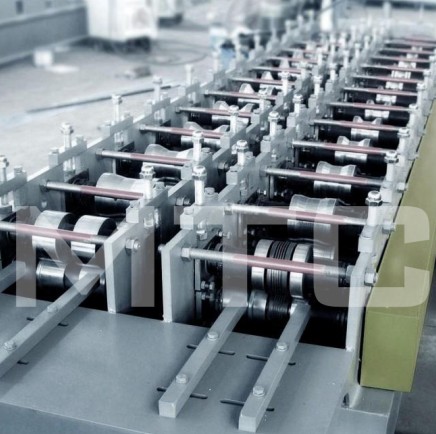

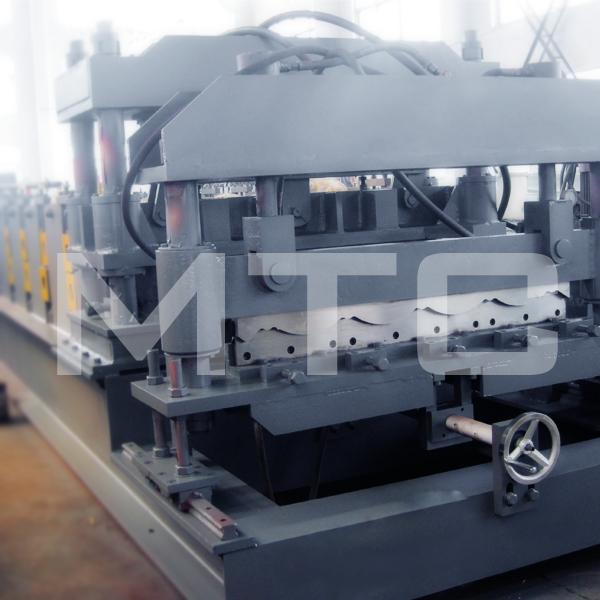

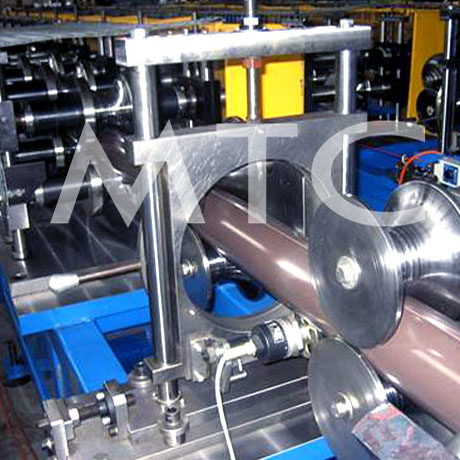

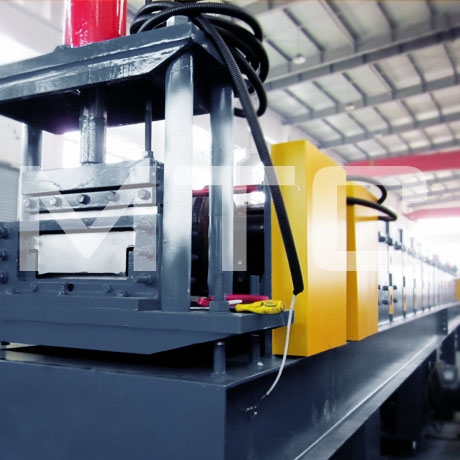

Roll Forming Machine (STEEL DECK FLOOR ROLL FORMING MACHINE)

Roller Stations: 28-36 stations

Diameter of Shaft: 70mm

Material of Shaft: 45# steel.

Material of roller: 45#steel with electroplating treatment after quenching treatment.

Forming speed: 8-12m/min

Siding Plate: 36 “H” Steel (Thickness 18mm).

Transmission: 1.0” Chains-bracket.

Bearing Model: 6210

Main Power: 2x11KW;

Overall Dimensions: 11500mmx1500mmx1300mm

Weight of the machine: Appro.14 Tons

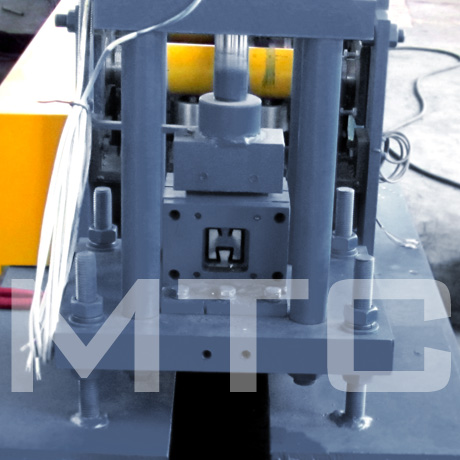

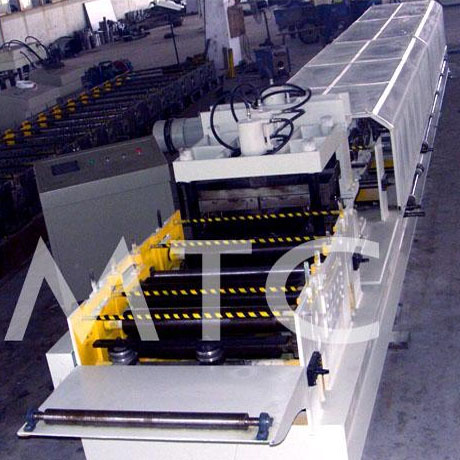

Cutting and Electrical Parts FOR STEEL FLOOR DECKING ROLL FORMING MACHINE:

Hydraulic Cutting: Automatically cutting according to the length and quantities the clients set on the touch screen

Hydraulic Power: 4KW

Material of Cutting Blades: Cr12 Steel

PLC Control Box: 700mmx1000mmx300mm

Computer Control System: Panasonic PLC.

Pressure of Hydraulic Station: ≧16Mpa

Website:www.mtc-china.com

Tel:86-21-67228332

Fax:86-21-67228302

Shanghai MTC Industrial Co.,ltd

Address: XingTa Industry Park,Jinshan District, Shanghai of China. , Fengjing , Shanghai, China, 201501

Tel: 0086-21-67228332

About Our Company:

MTC (Maxon Technology Corp.) is specialized in designing and manufacturing various cold roll forming machines and insulated sandwich panel production lines in China. With the development of the new age,MTC now presents the most advanced and innovative technology in its main products,such as roll forming machines, insulated sandwich panel production lines,slitting and cut-to-length machine lines,hydraulic decoilers,and some auxiliary machines etc.

About Our Service:

WE HAVE CE CERTIFICATE FOR OUR MACHINES AND PROVIDE 2 YEARS OR 5800 WORKING HOURS WARRANTY FOR OUR EQUIPMENT SINCE DELIVERY. In case of any damages or defects caused by the quality of our production technology,we will take in charge of any breakdowns within the warranty and we will provide duly service for maintenance in the whole life circles of the machines. Technicians will be sent to make installation and to train your craftsmen how to operate the machine until they can operate the machine proficiently.

About Our Culture:

Business Mission: Make True Change.

True change will be made, not only said, to enable our partners have a better experience with us.

Business Principles: Quality First, Service Next, and Money Last.

Only quality and service were greatly satisfied, would partners be pleased to buy one more time.

Business Values: Coordination,Circumspection and Innovation.

There is no "I" in MAXON, only coordinated with each other, and being circumspect, our team could innovate satisfactory products for our partners.