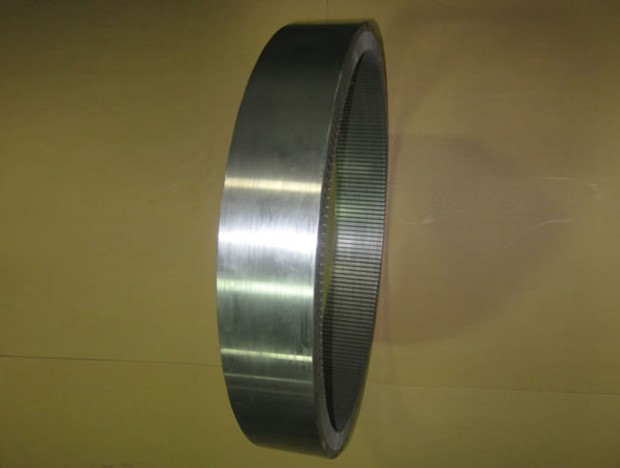

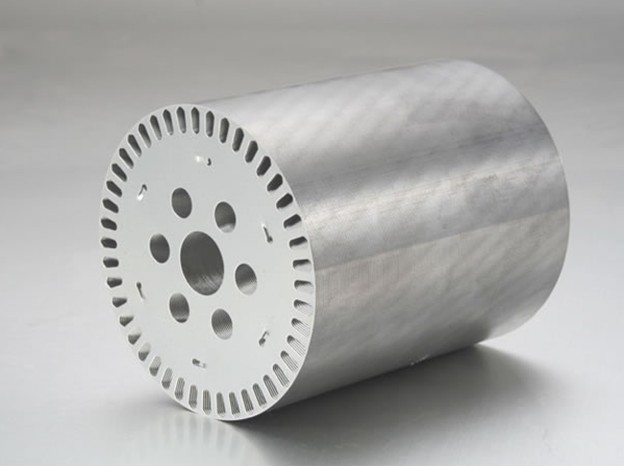

Linear Motor Stator Core - NO

Linear Motor Stator Core For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Linear Motor Stator Core, Made in China, High Quality Products!, China Electric Motor Parts, Electric Motor Stator Core Supplier, Manufacturer.

Product Description

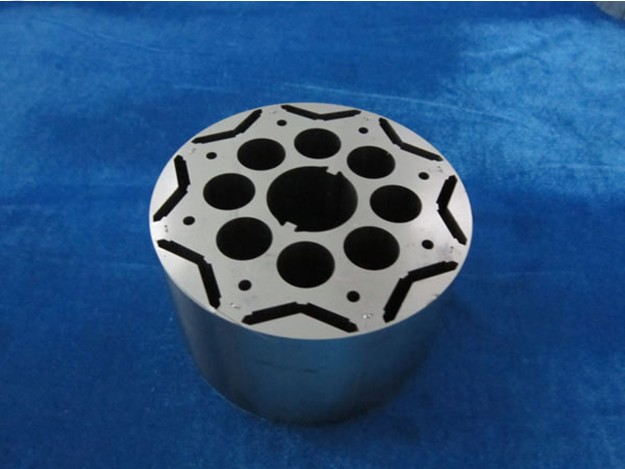

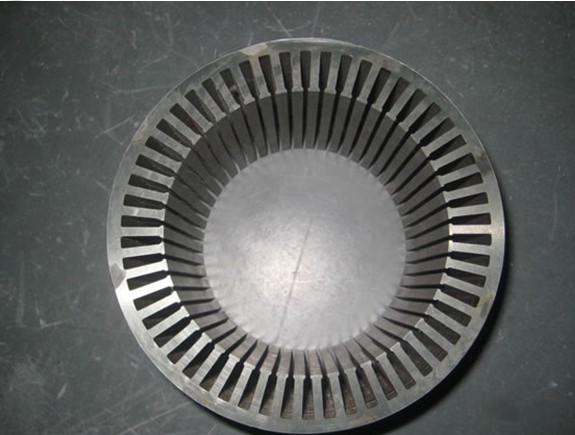

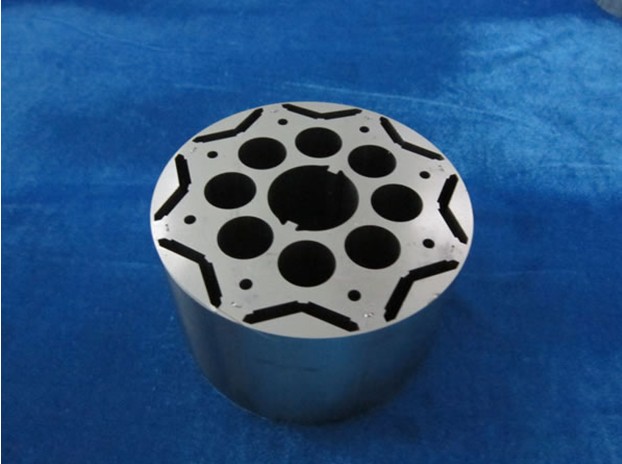

The linear motor stator core generally has teeth and slots, so we are fitted with updated high-speed punching machine to enhance the quality and performance. Besides, our excellent technology team is always ready to help, because better user experience is our goal. With 10-year history of manufacture, our quality-ensured linear motor stator core is exported to Western Europe and America. Meanwhile, our perfect location is the advantage to drastically reduce material cost. We are situated in the New District of Hangzhou Bay in Ningbo City, and there are many mold factories and famous ports around the area. So we can always choose molds with higher price-performance ratio.

For more service information, please contact us.

http://www.phasemotors.com/electric-motor-stator-core/1222565.html

http://www.phasemotors.com/electric-motor-stator-core/

Phase Industrial Design Ningbo CO., Ltd.

Address: Room 1203, Fengting (F) Building, Hefeng Chuangyi Square, No.375 JiangDong North Road, JiangDong , Ningbo, Zhejiang, China, Ningbo, Zhejiang, China, 315800

Tel: 86-574-27809638

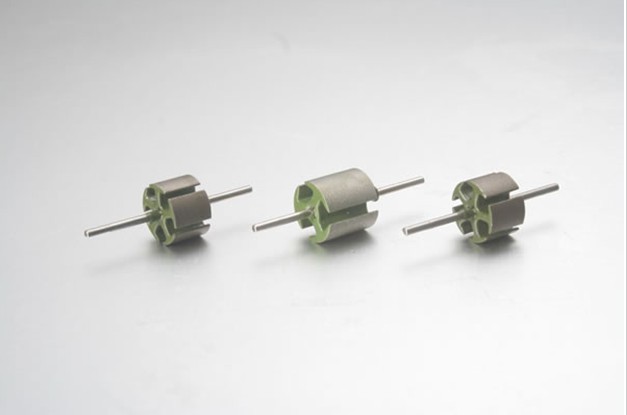

Phase Industrial Design Ningbo Co.,Ltd. is a state-level high-tech enterprise, the production center is located in Hangzhou Bay New Zone of Ningbo, and the sales office is in Ningbo city center; the company was established in 2001, to undertake professional foreign customization motor, motor parts and magnetic device processing production and assembly. The company has self-import and export rights, our customers are mainly distributed in Europe and North America and other countries. Ningbo Phase has accumulated more than 10 years of practical operation experience in magnetic assembly technology and electrical motor manufacturing. We can provide improvement proposal on customer`s design combining with actual production and clients technical communication in order to produce the best combination of theory and practice; especially in the early stages of the products development, we can simulate or optimize the customer`s mechanical design by drawing on the 3D (Solid works and Pro E) graphics software, to select different production ways with the least input to make out the samples.

www.phasemotors.com