Lead-in nozzle - n/a

Lead-in nozzle For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Lead-in nozzle, Made in China, High Quality Products!, China Lead in nozzle, welding nozzle Supplier, Manufacturer.

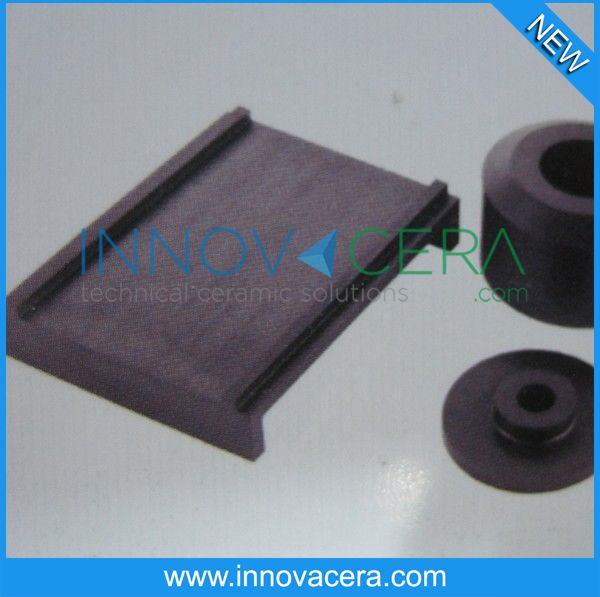

Lead-in Nozzle

Raw material:b4c,al2o3,sic

shape:banana nozzle,straight bore nozzle

angel nozzle,lead-in nozzle,venturi nozzle

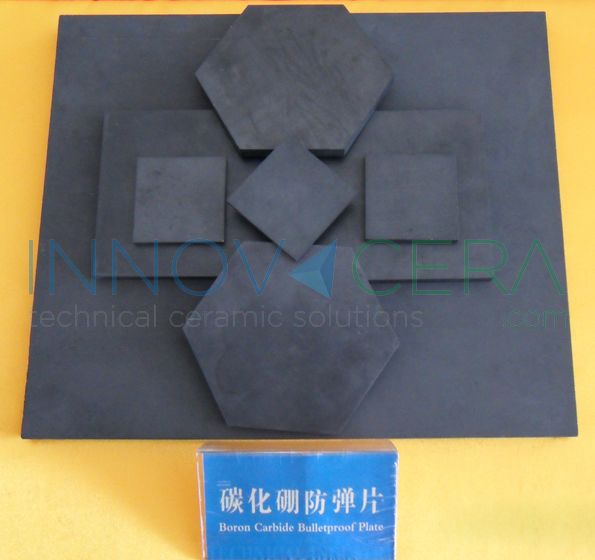

Boron carbide production flow:

Mould process,mixing,cold,pressing,assembling,hot pressing,machining,inspection,marking,packing

Boron carbide applications:

1.1. abrasive tield:surfaces of watches and jewels

2.2. ceramics materials:as materials made of boron carbide products and wear resistant components using in blasting sealing,machinery,ships,auto,dies,aviation and aerospace industries

3.3. boriding agent:boron carbide is a raw material used in boriding agent.After the treatment,the hardness and the wear resistance of the surface are greatly improved.

4.4. Solid fuel:boron carbide based propellants for ducted rockets

5.5. Nuclear Industry: boron carbide is an important material for nuclear applications due high absorption cross section

6.6. Armor Tiles:High density boron carbide armor tiles,bullet proofing seats of helicopters.

7.7. Chemical additives:Because of boron carbide good chemical resistance,for producing other boron containing materials such as titanium boride or zirconium boride.

8.8. Refractory materials:As an antioxidant additives in refractory field.

Xiamen Innovacera Advanced Materials Co.,Ltd

Address: Room 615,No.398 Jiahe Road Huli district, Xiamen , Fujian, China, 361006

Tel: 0086 592 5589731

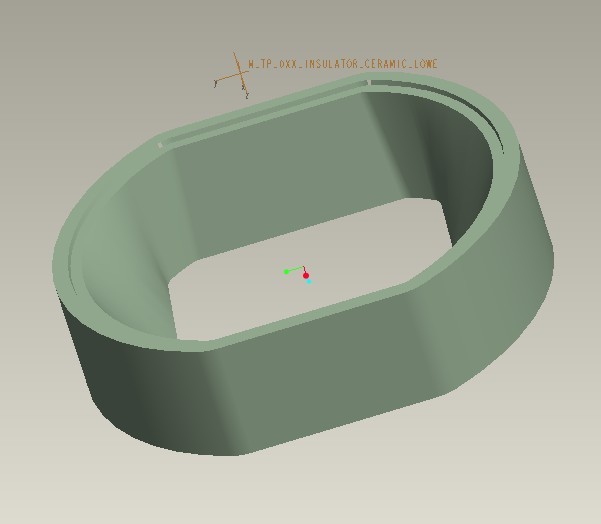

As a manufacturer of technical ceramic products, Innovacera main business is produce metallization ceramics and ceramics components as customer request.

Ceramic materials offer unprecedented possibilities for many industries, especially when products and components with extreme material properties are required. ceramic material including Aluminium Oxide, Zirconium Oxide, Silicon Carbide, Boron Carbide, Silicon Nitride and Boron Nitride.

Innovacera offer you a wide range of production facilities like extrusion, injection moulding, pressing and casting. Depending on product geometry and quantities, we will choose the suitable technique for your products.

For the final finishing of the parts we use CNC machining centres, equipped with diamond tools in order to meet high accuracies.

Innovacera products widely used in Aerospace, Research, Food Processing, Fluid Handling, Scientific, Automotive, Defense, Thermal Processing, Electrical, Process Control, Textile & Wire, Pulp & Paper, Mechanical, Glass Processing, Mineral Processing as well as smaller niche markets.

Our goal is to put the often extreme properties of technical ceramics to the best use.