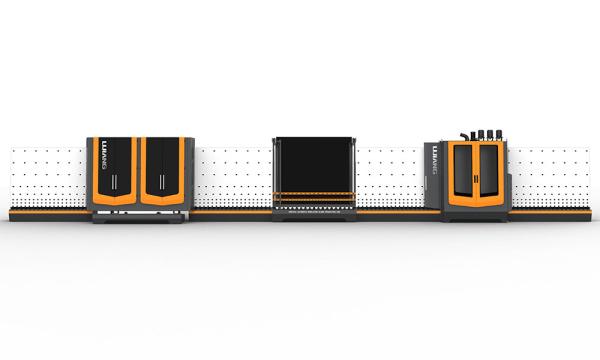

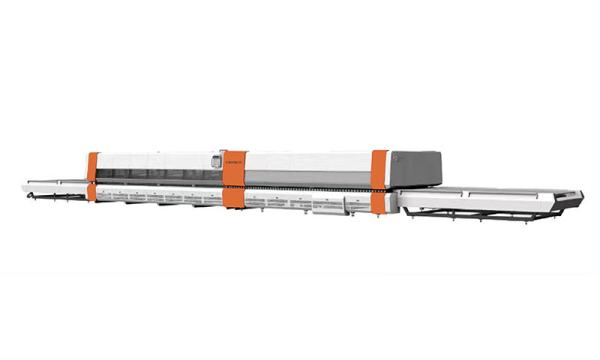

Laminated Glass Cutting Machine

EG-LGC-3826

Automatic Laminated Glass Cutting Machine can Automatic transmission and positioning of glass according to the cut size of input.

①.Man-machine interface HMl setting system parameters such as glass width length under knife pressure. etc--mechanical placement of glass into the synchronous belt area of the cutting table;

②Automatic transmission and positioning of glass according to the cut size of input (There's a location system)

③Knife head at zero -Pneumatic lower knife, upper and lower knife wheel cut (There's an automatic injection system)-Cut and lift-The up perpress starts the press, and the lower surface glass breaks open--Under the top rod up the glass, the upper surface of the glass break open--Heat bar start heating -The vacuum suction cup absorbs the glass on both sides of the tangent line and pulls the cutting seam apart

④Cutting film (PVB or EVA)--The cutting action is complete and the entire artifact is transferred to the next segment tangent position(lf you need to turn around and cut you need to do it manually)

⑤Manually move the processed glass to the lower slide flip bracket with the air float assembly.

Model | Maximum Glass Size (mm) | Thickness of Laminated Glass (mm) | Linear Precision(mm/m) | Glass Cutting Speed(m/min) |

EG-LGC-3826 | 3800x2600 | 3+X+3mm-8+X+8mm | ±0.15 | Cutting twice in one minute |

Motor | Delta SERVOMOTOR |

Drive | Delta |

Plc and touch screen | Delta |

Knife wheels | Made from Japan |

Transmission belt / pulley | Italy Babeli |

PU plate | American imported |

Proportional control valve | SMC Japan |

Cutter wheel / cutter | Germany Bohle |

Table | Imported industrial felt (black) |