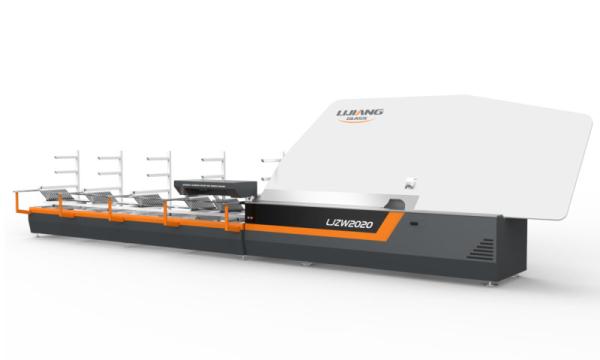

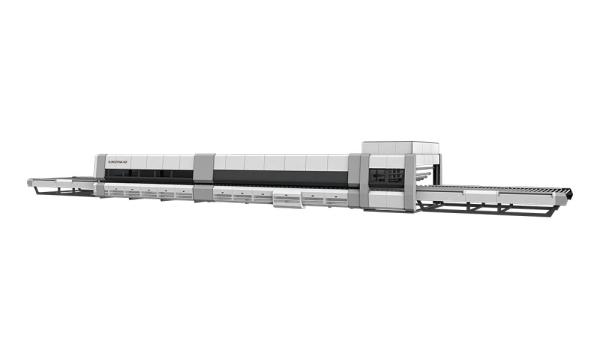

Jumbo Size Double Gas Filling Insulating Glass Production Line

EG-IG-3370

Maxmum glass size:3300*7000mm

Flat glass thickness:3-30mm

Washing brushes :6Pieces

Vertical Insulating Glass Processing Line to make glass processing more simple,intelligent and efficient.

•Germany Siemens PLC control system, touch screen interface

•Automatic identification of coated and Low-E glass

•3 pairs of soft brushes can wash online and offline Low-E glass

•The washing machine adopts SS material and waterproof device

•Water tank with automatic temperature control and water washing system

•Air heating system

•Air Fan automatic start and stop setting

•Noise reduction system

•Online display of washing speed

•Intelligent intermittent work, saving energy

•Adjustable pressing board to keep the plate pressing surface straight

•Connection mode of aviation plug

•Applicable to produce triple IG and shaped IG

Main Features of Automatic Insulating Glass Production Line

• Automatic Insulating glass production line has 7 sections

• 01 transfer section

The transfer section is a loading zone conveyor that is designed to load glass sheets into the washing machine. The transfer section is equipped with Coating detection mechanism, automatic detection of offline Low-e film.

• 02 Glass washing and drying section

Main feature

•In order to avoid corrosion we use stainless steel where there is a contact with the water in our machine body. The inside and outside of the machine is made of high quality stainless steel.

• Using 6 pieces of soft brushes with 0.1mm soft hair, can wash low-e glass

• Pre-washing (Optional)

• New air knife uses aluminum profile (Duckbill Air Knife), the size of the air outlet is adjusted by the aluminum profile duck beak. This can reduce the number of adjusting screws, ensure that each screw is not loose, and avoid the resonance of the air knife.

• The air knife can automatically adjust the width of the air knife according to the thickness

• The operation box with washing speed display, can accurately display washing speed (8-10m)

• Water tank automatic temperature control, water replenishing system

• European silencer system

• Stainless steel material

• 03 discharge section

• Storage glass

• 04 inspection and installation section

The new structure of this section is changed to an inline beam lifting structure (double beam). It is easy to inspect and wipe the glass

• 05 transfer section

• Automatic measurement of glass thickness. It can be used according to actual needs when working.

• 06 pressing and filling section

| Voltage | Unit | 380V50Hz3P |

| Total power | KW | 54.5 |

| Washing speed | m/min | 2~10 |

| Maximum working speed | m/min | 45 |

| Minimum glass size | mm | 450*280 |

| Maxmum glass size | mm | 3300*7000 (once) |

| 3000*3000 (twice) | ||

| Flat glass thickness | mm | 3-30 |

| Washing brushes | Pieces | 6 |

| Maximum thickness of insulating glass | mm | 80 |

| Total gas consumption | L/min | 1500 |

| Conveyer roll height | mm | 520 |

| Dimension | mm | 47200*3500*4500 |