JTH Superior Metal Stamping Auto Parts Mould , 3D Metal Forming Dies - AIA-1

JTH Superior Metal Stamping Auto Parts Mould , 3D Metal Forming Dies For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale JTH Superior Metal Stamping Auto Parts Mould , 3D Metal Forming Dies, Made in China, High Quality Products!, China cheap prodocuts, china suppliers Supplier, Manufacturer.

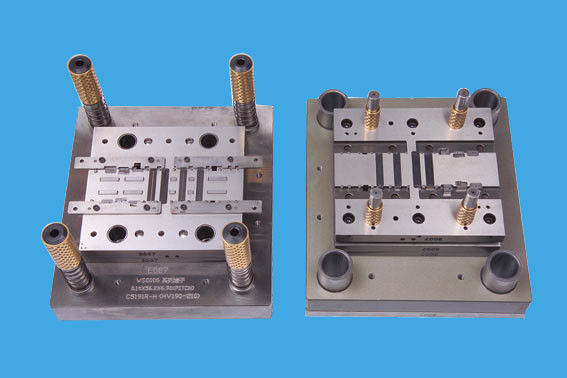

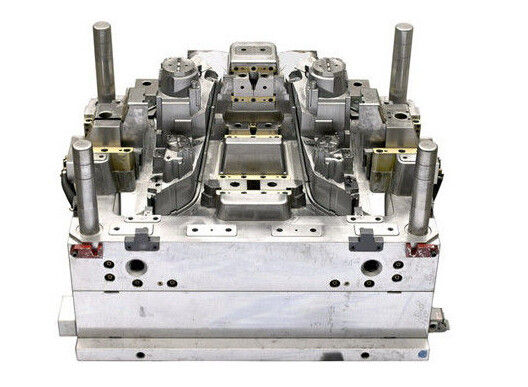

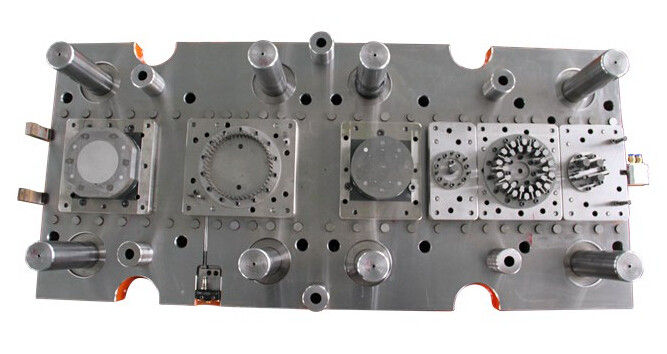

JTH Superior Metal Stamping Auto Parts Mould , 3D Metal Forming Dies

?

Features:

?

1. We are directly manufacture have rich experience in OEM stamping products with very competitive price

2. We can manufacture precision stamping part in electric product, telephone, watch, automobile, etc. Material include

3. Many kinds of surface treatments are available: zinc platein, nickel platin,chrome plating,powder coating,e-coating phosphate coating,etc.

4. Normal dimensions are controlled according to middle class tolerance specified in ISO and PS16949

5. We can work for a variety of drawing file:UG,Pro/E,Solid works,AutoCAD etc.

6. We can make die by ourselves

7. we provide thickness form 0.15 to 2.00mm?

?

Pruduct details:

?

auto mould(for car parts mould)

?

1. reasonable price;?

2. excellent quality;?

3. extended life;?

4. on-time delivery?

5. good after-service

?

Production process flow:

1. “mould tooling specification” reqirement from client,after client release order,The sheet will copy to our design,inspection and tooling department.

2. we will make tooling and processing schedule sheet during mold’s design.

3. mould 3D design will be done according to client’s requirement.

4. mould flow ananlyse.

5. we will offer the 2D drawing to client,let client approval.

6. your mould is tooling and assembling.

7. our inspection department will flowing and controlling the tooling processing.

8. Mould Test and injection moulding spot report ,we’ll send you report with the samples by air carrier.

9. mould will be checked by ourself.

10. the client’s confirmation for shipment.

11. finish mould before delivery.

?

Specifications:

?

- - - -

Material | SPCC, SUS304/303, SECC, carbon steel, CRS, HRS, mild steel, spring steel, aluminum, brass, copper, etc. |

Thickness | 0.1mm~10.0mm |

Applied software | PRO/E, ACAD |

Process | sheet metal mould, stamping mould and auto progressive die for appliance and automobile product, offering the service on machine part, etc |

Design & Manufacture | Wire-cut, Milling machine, Precision Grinder machine, etc |

Application Fields | Hardware, household, automobile, |

Delivery? time | Depends on different product. |

Packaging | Suction? Plastic? Plate, ? PE? Bag, ? Foaming? Filler, ? Blister plate and Carton |

Equipment | sodic WEDN, face grinding machines, Taiwan CNC processing center, oil pressure, tryout equipment etc. |

Certification | SGS |

- - - -

?

?

Jintaihua Precision Molds Co.,Ld

Address: China guangdong shenzhen baoan district, Shenzhen, Guangdong, China, 518000

Tel: 86-135-90287963

Shenzhen Jin Taihua metal products co., LTD. Was established in June 2000, is located in baoan shajing xinqiao furong industrial zone, convenient transportation and superior geographical environment, is a professional engaged in precision metal mold design and production, metal stamping products, accessories, all kinds of oven door buckle, locks and chassis cabinets manufacturing, precision machinery parts processing, non-standard equipment design and manufacture of professional manufacturers. Now has complete production with the CNC computer gongs, computer lathe, automatic lathe, CNC milling machine, surface grinding machine, shearing machine, bending machine, line cutting machine, 16 t - 100 t punching machines and other processing equipment more than 80, the company factory building area of more than 1800 square meters, more than 100 employees, including research and development and technical personnel for 3 people, quality management personnel 8 people, production and technical personnel account for five people. Insist on development, innovation, quality, service, good faith for the company development.