ISO9001 2008 Cemented Carbide Products for Cold Stamping , Tungsten Carbide Tooling - AIA-1

ISO9001 2008 Cemented Carbide Products for Cold Stamping , Tungsten Carbide Tooling For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale ISO9001 2008 Cemented Carbide Products for Cold Stamping , Tungsten Carbide Tooling, Made in China, High Quality Products!, China cheap prodocuts, china suppliers Supplier, Manufacturer.

ISO9001 2008 Cemented Carbide Products for Cold Stamping , Tungsten Carbide Tooling

?

?

Description:

?

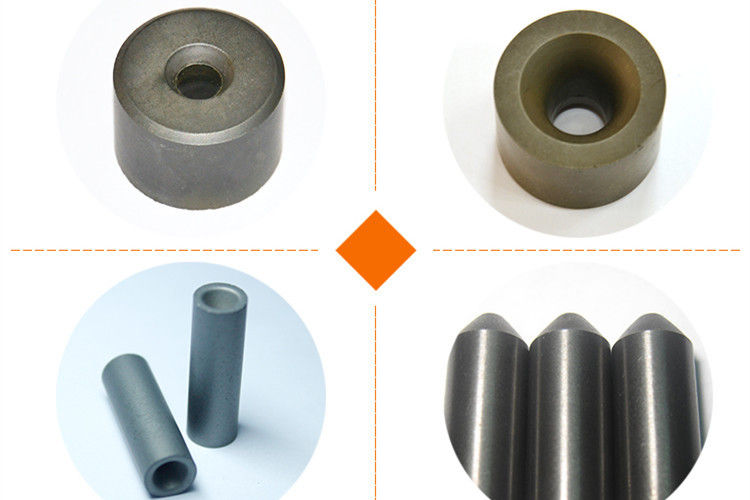

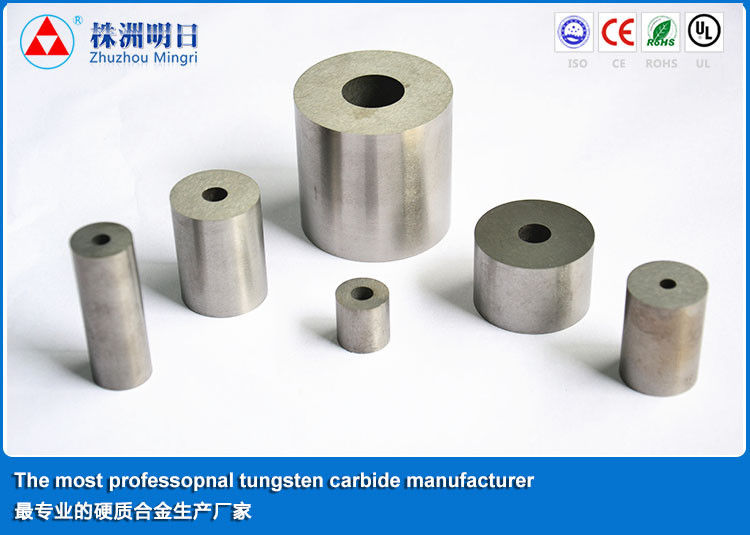

1.The?grade?GT55/YG25C?is?the?most?widely?used?material?in?making?carbide?pellets.?

?? It?has?excellent?properties?which?lead?to?good?performance?and?long?service?time.

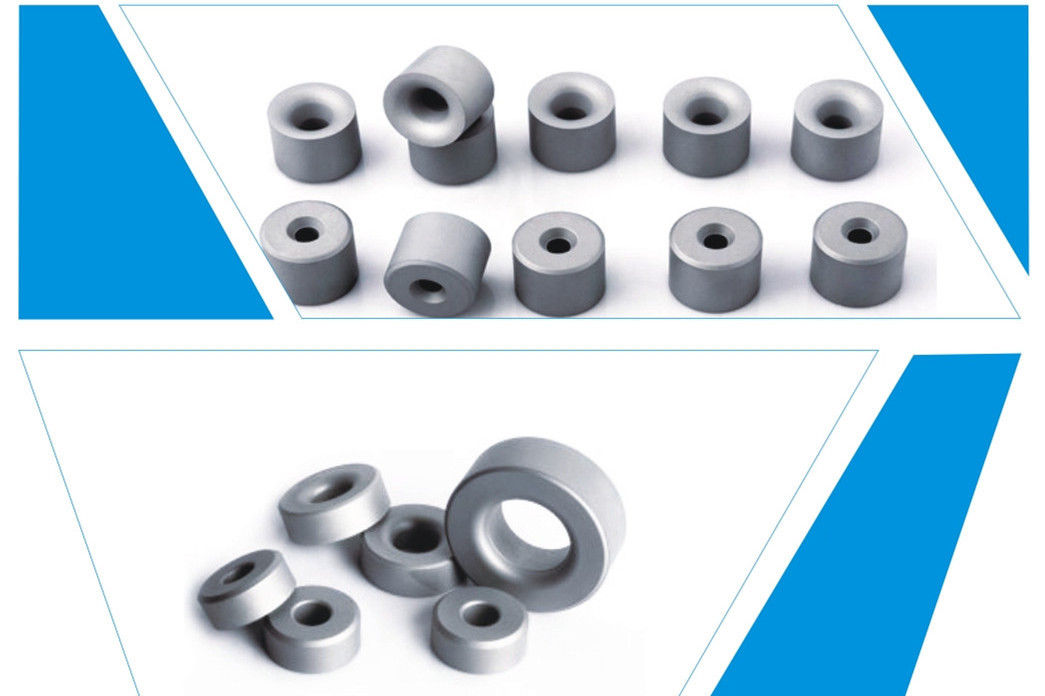

2. Cemented?carbide?pellets?are?widely?used?in?cold?heading?dies?and?punching?dies?

?? for?manufacturing?nuts,?bolts?and?many?other?products.

3. Except?for?the?standard?sizes,?nonstandard?sizes?of?carbide?pellets?

?? can?also?be?produced?according?to?customer& acute;s?requirements.?

4. All?carbide?pellets?inspected?strictly?with?ultrasonic?flaw?detector?

?? to?avoid?ones?with?blowholes?or?cracks?leaving?the?factory.

?

Applications:

?

Cemented?carbide?pellets?are?widely?used?in?cold?heading?dies?and?punching?dies?

for?maufacturing?nuts,?screw?caps,?bolts,?cans?and?many?other?products.

?

Grade:

- - - -

Grade | Density

g/cm3 | T.R.S

MPα | Hardness

HRA | Properties & Applications | Approx Grades in China |

A | 13.5 | 3000 | 83.5 | Good wear resistance and? bending strength. It is often preferrd by? nut forming dies and high impact-resistant dies. | — |

YM11 | 14.4 | 2420 | 88.5 | Forming or stamping dies for metal powders and nonmetal powders. | YG11 |

YM15 | 14.0 | 2500 | 87.5 | It is suitable for drawing steel tubes and rods under high compression ratio, manufactuing upsetting, punching and forging tools under large stress. | YG15 |

YM20 | 13.5 | 2800 | 85.5 | It is suitable for manufacturing punching dies for watch parts, leaf spring of musical instruments, battery jars, small sized steel balls, screws, screw caps, etc. | YG20 |

ML32 | 13.9 | 2750 | 85.5 | It is suitable for impact-resistant forging dies. | YG16C |

ML36 | 13.7 | 2800 | 84.5 | It is suitable for impact-resistant forging dies, hot-forging dies and finishing rollers. | YG18C |

ML40 | 13.5 | 2850 | 83.5 | It is suitable for wear resistant or impact resistant dies. | YG20C ZL40.2 |

ML50 | 13.3 | 2900 | 83.0 | It is suitable for nut forming dies and high impact-resistant dies. | YG22C ZL40.5 |

ML60 | 13.1 | 2950 | 82.5 | It is suitable for stainless screw dies and semifinishing rollers. | YG25C ZL40B |

ML80 | 13.1 | 3050 | 83.4 | It is suitable for screw cap forming dies with high strength ( highest impact-resistant forging dies). | YG25C GT55 |

Other grades of cemented carbide blanks for cold-forging dies may be offered by customers& acute; requirements |

- - - -

?

Specifications:

Including?but?not?limited?to?the?following?types.

- - - -

Type | ?

?Dinension |

Appllcable | ? |

? |

d | D | L?

Range?of?L | ? |

BDP00710- | 0.7 | 10 | 12.0-20.0 | M1 | ? |

BDP01010- | 1.0 | 10 | 12.0-20.0 | M1.5-M2 | ? |

BDP01013- | 1.0 | 13 | 15.0-40.0 | M1.5-M2 | ? |

BDP01213- | 1.2 | 13 | 15.0-40.0 | M1.5-M2 | ? |

BDP01510- | 1.5 | 10 | 12.0-25.0 | M2 | ? |

BDP01516- | 1.5 | 16 | 15.0-45.0 | M2 | ? |

BDP01813- | 1.8 | 13 | 12.0-45.0 | M2.5 | ? |

BDP01816- | 1.8 | 16 | 20.0-45.0 | M2.5 | ? |

BDP02113- | 2.1 | 13 | 15.0-30.0 | M3 | ? |

BDP02116- | 2.1 | 16 | 25.0-45.0 | M3 | ? |

BDP02316- | 2.3 | 16 | 15.0-45.0 | M3 | ? |

BDP02522- | 2.5 | 22 | 20.0-60.0 | M3 | ? |

BDP02813- | 2.8 | 13 | 15.0-30.0 | M4 | ? |

BDP02816- | 2.8 | 16 | 25.0-40.0 | M4 | ? |

BDP02818- | 2.8 | 18 | 20.0-50.0 | M4 | ? |

BDP02820- | 2.8 | 20 | 20.0-50.0 | M4 | ? |

BDP02822- | 2.8 | 22 | 20.0-60.0 | M4 | ? |

BDP02825- | 2.8 | 25 | 20.0-60.0 | M4 | ? |

BDP03216- | 3.2 | 16 | 15.0-45.0 | M4 | ? |

BDP03218- | 3.2 | 18 | 15.0-50.0 | M4 | ? |

BDP03616- | 3.6 | 16 | 20.0-50.0 | M5 | ? |

BDP03618- | 3.6 | 18 | 20.0-60.0 | M5 | ? |

BDP03822- | 3.8 | 22 | 20.0-40.0 | M5 | ? |

BDP03830- | 3.8 | 30 | 50.0-60.0 | M5 | ? |

- - - -

?

Package

?

Zhuzhou Mingri Cemented Carbide Co., Ltd.

Address: Add: No. 88, Mingri Road, Liyu Industrial Area, Zhuzhou, Hunan, China, 412000

Tel: 86-731-22778506

Company Profile

Zhuzhou Mingri Cemented Carbide Co., Ltd.

Located in Liyu Industrisl Area, Zhuzhou City, Tianyuan District, Hunan Province, Zhuzhou Mingri Cemented Carbide Co., Ltd was established in May of 2001 with the investment of RMB 40 million. We own up-to-date production line, advanced equipment, lots of technicians. We have passed ISO 9001:2008,ISO 9001:14001. And we have been always trying our best to provide our customers with high quality , best price and satisfactory services.

Zhuzhou Mingri Cemented Carbide Co., Ltd.

We specialize in series of tungsten carbide products, such ascold forging die cores, brazed tips, disc cutters, plates and boards, saw tips, round rods, rock drilling bits and buttons, milling tools, geological exploration drill tools and so on. Our production are exported to UK, European, Japan, Taiwan and South-east Asia etc.

You` re welcome to have a visit to our factory!