IG Glass, IGU, Insulating Glass Units, Insulating Glass Machine

Insulating glass (IG) commonly consists of two (sometimes more) panes of glass separated by a spacer material and sealed together at the edge. The insulating airspace is filled with air or a noble gas, such as argon or krypton inside. Using argon or krypton in the air space between the two panes of glass provides further insulation, as these gases are denser than air and less likely to let heat conduct through the IGU. Combined with a low-e glass coating, these gases work to improve the window’s overall u-value, which is a measure of the heat transmission through a building part (such as a wall or window). The lower the u-value, the better the insulating glass unit. When 90% argon gas fill is used in a low-e IGU instead of air, the window’s u-value can be improved by up to 16%. Similarly, krypton improves the u-value in a low-e IGU by up to 27%. However, using a noble gas instead of air in an IGU can add both time and cost to the window’s construction.

What is an IG Insulated Glass?

Insulating glass (IG) commonly consists of two (sometimes more) panes of glass separated by a spacer material and sealed together at the edge. The insulating airspace is filled with air or a noble gas, such as argon or krypton inside. Using argon or krypton in the air space between the two panes of glass provides further insulation, as these gases are denser than air and less likely to let heat conduct through the IGU. Combined with a low-e glass coating, these gases work to improve the window’s overall u-value, which is a measure of the heat transmission through a building part (such as a wall or window). The lower the u-value, the better the insulating glass unit. When 90% argon gas fill is used in a low-e IGU instead of air, the window’s u-value can be improved by up to 16%. Similarly, krypton improves the u-value in a low-e IGU by up to 27%. However, using a noble gas instead of air in an IGU can add both time and cost to the window’s construction.

What is an Insulated Glass Unit (IGU)?

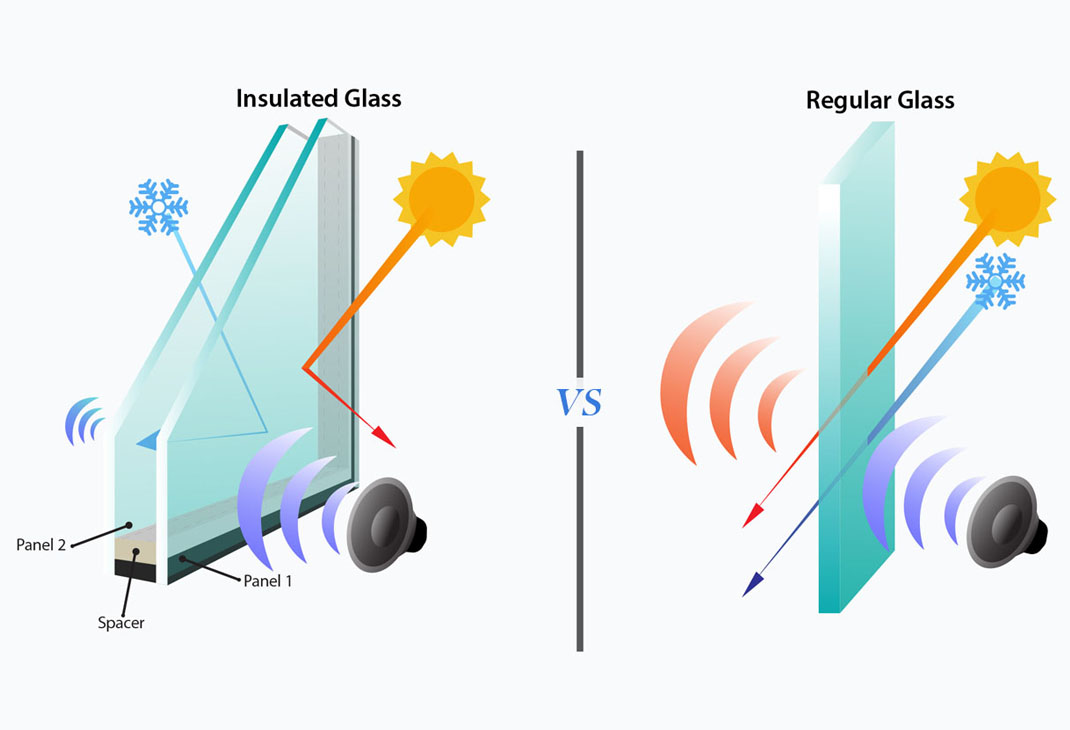

Insulated glass is often referred to as a unit: IGU-Insulating Glass Units, since most of the parts are dependent on another for proper performance. The IGU will keep the heat in during the cold weather and will retain the heat out during the hot weather. Coatings are applied on the interior of IGUs to reflect UV light back into homes to retain warmth, or on the outside to keep sunlight from heating up a home. The IGU can give a greater value when conjunction with Low-E and reflective coated glass. Low-E glass should always be insulated with the coating to the inside (surface #2). Unlike single-pane glass, IGU glass panes are part of a sealed system that can’t be replaced individually. Insulated glass units go by different names, including: “double glazing” or “double-pane glass windows.” IGU improve thermal performance, significantly reducing heating and air conditioning costs. IG units or “double-pane” glass are usually used in residential, commercial and industrial constructions. These types of IG Units are required by building codes in many areas as mandatory energy conservation measure.

How to Make Insulated Glass?

Insulating glass production process needs to go through multiple process steps, including glass cutting, glass cleaning, glass inspection, glass coating, insulating glass assembly, vacuum adsorption, gas injection filling and sealant curing. Every process step is very critical. Only when each step is handled well can high-quality insulating glass products be produced.

1. In the process of glass cleaning, it is necessary to use professional cleaning equipment and cleaning agents to ensure that the glass surface is clean and smooth, and to avoid defects or affect its performance in the subsequent process. Some large insulating glass production lines will also be equipped with automatic cleaning equipment, which can improve production efficiency and cleaning quality. At the same time, it is also necessary to pay attention to safety issues during the cleaning process to prevent workers from being injured.

2. In the glass inspection process, optical equipment is usually used to inspect the glass surface. These devices can detect various defects on the glass surface, such as cracks, blemishes, bubbles, etc. The defective glass plates will be rejected to ensure the reliable quality of the produced insulating glass products. At the same time, these optical devices can also detect whether the size and shape of the glass plate meet the requirements, so as to ensure the assembly accuracy of the insulating glass.

3. In the fourth process of the insulating glass production line, glass coating is a very important step. Through coating treatment, the heat insulation and sound insulation performance of insulating glass can be effectively increased, and its use effect can be improved. The main technologies used in glass coating are hot-dip method, spraying method and ion plating method. Among them, the ion plating method is a relatively advanced technology, which has the advantages of uniform coating and high precision of thickness control. In addition, the material of the coating is also very important. Common coating materials include zinc oxide, fluorocarbon, etc.

4. During the assembly process of insulating glass, two or more glass plates need to be assembled together according to a certain distance, and sealant strips are installed at both ends to form a closed hollow structure. When assembling, it is necessary to pay attention to the distance between the glass plates should meet the design requirements, otherwise it will affect the performance of the insulating glass. At the same time, when installing the sealing strip, it is necessary to ensure the quality and bonding effect of the sealing strip to ensure the airtight performance of the insulating glass.

5. In the process of making insulating glass, vacuum adsorption is a very critical step. By extracting the gas in the hollow part, the heat conduction can be reduced and the heat insulation performance of the insulating glass can be improved. Usually, the time of vacuum adsorption needs to be determined according to the size and thickness of the insulating glass, so as to ensure that the pressure of the hollow part reaches a predetermined value.

6. After vacuum adsorption, gas injection filling is required immediately, and the desired gas is poured into the hollow part. In this way, gas leakage can be avoided, and at the same time, it can ensure that the insulating glass has good heat insulation and sound insulation performance. In the gas injection filling process, the desired gas (such as argon, air, etc.) needs to be injected into the insulating glass. When injecting gas, it is necessary to ensure the accuracy and uniformity of the amount of gas injected to avoid bending or breaking the glass plate due to uneven gas pressure inside the insulating glass. At the same time, the insulating glass needs to be pre-vacuumized before gas injection to ensure that there are no bubbles and impurities inside the glass. After the gas injection is completed, the insulating glass needs to be cured with sealant to ensure its airtight performance.

7. Sealant curing: Carry out sealant curing treatment on insulating glass to ensure its airtight performance.

8. Insulating glass inspection: conduct a comprehensive inspection of the manufactured insulating glass to ensure that its sealing performance, heat insulation performance and other indicators meet the requirements.

9. Finished product packaging: Pack the insulating glass that has passed the test according to certain specifications, and carry out quality identification and transportation identification.

10. Product storage: Put the packaged insulating glass into the warehouse for storage, and pay attention to moisture-proof, sun-proof, shock-proof and other measures to ensure that its quality will not be affected.

Insulating Glass Machine, Insulated Glass Production Line

Insulated glass production line is a kind of glass deep processing equipment, which is mainly used to process and make insulating glass unit. After cutting the original glass, it enters the insulating glass production line. It mainly goes through cleaning, drying, making spacer frames, filling desiccant, and the first seal (coated with butyl rubber)., inspection, frame placement, sheet pressing, second sealing (polysulfide glue or silicone glue), and next sheet. The insulating glass deep-processing products produced by the process are of high quality and fast processing speed.

The Insulating glass production line mainly has four sections: feeding section, washing and drying section, inspection section, and combining section. The four sections are placed vertically at the same inclination angle, with a compact structure, economical and practical, high efficiency, and convenient maintenance. The washing shell is made of stainless steel, and the conveying roller is an acid and alkali-resistant rubber roller; through the plexiglass window, the glass cleaning situation can be observed conveniently at any time; The speed runs smoothly. The drying section adopts a large wind-force inclined air knife to dry the glass surface. The inspection section is equipped with a light tube, which can check the washing quality of the glass; the combined section has glass positioning and aluminum frame positioning devices, which can complete the functions of glass positioning and aluminum frame positioning. The glass is supported and conveyed by the conveying rubber roller. The conveying roller is driven by the motor (roller pressing section motor) through the frequency conversion speed regulator through the sprocket. The glass enters this section at a low speed from the washing and drying section and accelerates to the next work after passing the inspection. section to improve work efficiency; the frequency converter controls the running speed of the speed-regulating motor in this section, and the photoelectric switch controls the glass to enter the next working section.