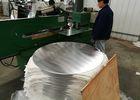

Hot Rolled Pure Strong Aluminium Discs Circles Alloy 1050 / 1070 For Cookware - Hot Rolled Pure

Hot Rolled Pure Strong Aluminium Discs Circles Alloy 1050 / 1070 For Cookware For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Hot Rolled Pure Strong Aluminium Discs Circles Alloy 1050 / 1070 For Cookware, Made in China, High Quality Products!, China cheap prodocuts, china suppliers Supplier, Manufacturer.

? Hot Rolled Pure Strong Aluminium Discs Circles Alloy 1050 / 1070 For Cookware ?

Quick Detal:

?

Aluminium Circle:

Alloy: 1*** 3*** 5*** 6*** 8***

Temper: O-H112,T etc.

Thickness: 0.5-4.0mm

Diameter: 200-800mm

Surface: Mill Finish

Technology:Hot Rolled & Cold drawn(cast)

Capacity:1500 tons per month

Payment: T/T or L/C at sight

Certificate: SGS/ISO/ROSH/FORM E etc.

Delivery Time :20-35 days after receipt of deposit

?

Description:

?

Cold Rolling/ Hot Rolling Aluminum Circles are widely used in furnitures like tables. But most aluminum circles clients requested are Deep Drawing Quality Aluminum Circle. These aluminum circle are widely

used in kitchenware, cookware, reflector-light etc.

Aluminum Circle Features:

1. Wide range of selection on circles& acute; size including customized shape and size;

2. Excellent deep drawing and spinning quality;

3. RoHS and REACH compliance.

?

The properties of aluminum circle for pots, cookware, non-stick aluminium circle (or shaped blanks) make

them ideal for use in a number of markets including the cookware, automotive and lighting industries etc

?

Key Features

1. Low anisotropy, which facilitates deep drawing

2. Strong mechanical properties

3. High and homogeneous heat diffusion

4. Ability to be enameled, covered by PTFE (or others), anodized

5. Good reflectivity

6. High strength-to-weight ratio

7. Durability and resistance to corrosion

?

- - - -

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Al |

1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | --- | --- | 0.05 | 0.03 | 99.6 |

1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | --- | --- | 0.05 | 0.03 | 99.5 |

1100 | 0.95 | 0.05-0.2 | 0.05 | --- | --- | --- | 0.1 | --- | 99.0 |

1200 | 1.0 | 0.05 | 0.05 | --- | --- | --- | 0.1 | 0.05 | 99.0 |

3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | --- | --- | --- | 0.1 | --- | remainder |

- - - -

?

Aluminum Sheet Processing:

Ingot/Master Alloys--->Melting Furnace--->Holding Furnace--->D.C.Caster--->Slab--->Homogenizing--->Hot Rolling Mill--->Cold Rolling Mill--->Punching--->Annealing Furnace--->Finish Inspection--->Packing--->Delivery

Mechanical Properties

TEMPER ? THICKNESS(mm) ?TENSILE STRENGTH ? ?ELONGATION% ? ? Standard

HO ? ? ? ? ? ? 0.35-10 ? ? ? ? ? ? ? ? ? ? ?60-100 ? ? ? ? ? ? ? ? ? ? ?≥ 20 ? ? ? ? ? ? ? ? ? ?GB/T91-2002

H12 ? ? ? ? ? ?0.5-10 ? ? ? ? ? ? ? ? ? ? ? ?70-120 ? ? ? ? ? ? ? ? ? ? ?≥ 4 ? ? ? ? ? ? ? ? ? ? ?GB/T91-2002

H14 ? ? ? ? ? ?0.5-10 ? ? ? ? ? ? ? ? ? ? ? ?85-120 ? ? ? ? ? ? ? ? ? ? ?≥ 2 ? ? ? ? ? ? ? ? ? ? ?GB/T91-2002

?

Aluminum circle Surface Quality

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Discoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use.

Aluminum circle Mechanical Property:

Chemical Composite and Mechanical Property could meet the requirements of GB/T, ASTM, ENAW, and JIS Standard

Aluminum circle Packing:

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

?

Producing Procedure from Aluminum Ingot to Aluminum Circles:

Aluminum Ingot/Master Alloys --- Aluminum Melting Furnace - --- Aluminum Slab --- Hot Rolling (Direct Cast) Or Cold Rolling (Cold Cast) – Punching – Annealing Furnace -- Final Inspection

?

Specifications:

?

- - - -

Product | Aluminum Circle |

Alloy | 1050 1060 1100 1200 3003 |

Temper | O, H12, H14, H18 and H24... |

Thickness | 0.3mm-6.0mm |

Diameter | 50mm-1600mm, Commonly 200mm to 700mm |

Lead Time | Within 30-45 days after receiving deposit |

Packing | Standard Exporting wooden pallets or based on customer requirement |

Material | Using high-tech machinery utilizing premium grade Aluminum Coil. |

Surface: | Bright & smooth surface, free from defects like white rust, oil patch, edge damage. |

- - - -

?

Applications:

?

Deep drawing cookware,

spinning cookware,

road sign,

Building Material,

Insulation,

and so on.

?

Competitive Advantage:

?

Though smelting, casting, hot-rolling, cold-rolling, heat-treatment, finishing and other technology,the heavy melting aluminum and an appropriate quality of alloying elements is processed to light nonferrous metal material which has the characters of fine luster, good looking, light weight, poison less and selflessness, and it also has good properties of transmitting electric current and heat, processing and corrosion-resisting applicability.

?

?

HENAN HOBE METAL MATERIALS CO.,LTD.

Address: No. 521-15, 5th Floor, Shili Building, Hongzhuan Road, Zhengzhou, Henan, China, 450000

Tel: 86-130-07527876

Hobe Aluminium is professional in manufacturing Aluminium Circle. Mainly producing Pure Aluminum Circle, like Alloy 1050, 1060, 1070, 1100 and Alloy Aluminium Circle, like Alloy 3003.

We are located in famous aluminium capital of Zhengzhou City, Henan Province. By using such kind of regional comparative advantage, we orient to provide the customers with high quality and substantial products at lowcost. Our Aluminium Circle is widely used in cookware, kitchenware, utensils, pot, kettle, non-stick pan, basin, bucket, frypan, tray, pressure cooker, traffic signs, furniture, lighting, lampshade, etc.

We would like to highlight our Aluminium Circle, with good physical performance, flat surface and smooth edge, Suitable for both deep drawing and Spinning.

We enjoy a good reputation among our customers for our aluminum circle with high quality and competitive price; win high appreciation from our clients with the excellent workman-ship and professional ability. The quality matches with ISO 9001 quality management system. We have 3 aluminium circles production line, and the annealing equipment.