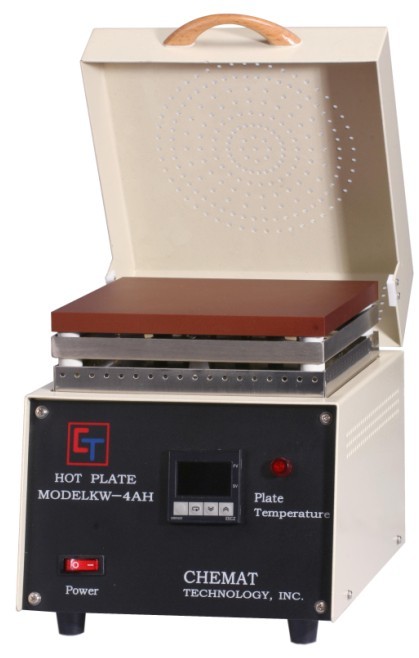

Hot plate for thermally curing the thin film - KW-4AH

Hot plate for thermally curing the thin film For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Hot plate for thermally curing the thin film, Made in China, High Quality Products!, China spin coater, dip coater Supplier, Manufacturer.

CHEMAT TECHNOLOGY, INC. Has designed and manufactured a compact and easy-to-use hotplate, Model KW-4AH, for baking and curing thin films and coatings. Its rugged, portable design, and temperature uniformity make it a versatile tool for research facilities. In conjunction with KW-4A spin coater, KW-4AH hotplate can be used to fabricate metal oxide thin films, polymer coatings and metal organic thin films.

Operation: Manual Load

Process Control: Program (For details see OMRAN operation manual)

Temperature fluctuation: ≤ ?1癈

Temperature uniformity: ≤ ?3%

Temperature Range:

?0癈 - 350癈 (KW-4AH-350)

?0癈 - 600癈 (KW-4AH-600)

Substrate Size:

?.5 inch X 7.5 inch(KW-4AH-350)

?.8 inch X 5.8 inch(KW-4AH-600)

Inert gas purge (KW-4AH-600 only)

Shanghai Chemat Advanced Ceramics Technology Co., Ltd

Address: 1355 Chengbei Road, Jiading, Jiading, Shanghai, China,

Tel: 0086-21-59167109

Founded in 1990, Chemat Technology Inc. has established itself as a world leader in the development of advanced materials via sol-gel technologies. Headquartered in Northridge, California, in the San Fernando Valley area of Los Angeles, Chemat moved in 1999 to a 34,100-foot office/industrial building. Its R&D labs are fully equipped with state-of-the-art analytical and processing equipment. Chemat owns facilities for chemical precursor synthesis, design and manufacturing of equipment, and advanced materials processing and characterization. Chemat has worldwide R&D operations.

Chemat抯 R&D Division has successfully completed over one hundred Research & Development contracts for government agencies and industry clients. It抯 mission is to provide the best solution based on the most advanced technologies with the sol-gel technology as the core to the targeted industry. Chemat staff includes professionals with Ph.D.'s and Masters degrees in Chemistry, Materials Science & Engineering, and Chemical Engineering.

Offered through its Scientific Division (www.chematscientific.com), Chemat has served R&D operations in institutions and industries for nearly two decades by supplying specialty chemical precursors and equipment. A complete line of chemical precursors for sol-gel processing is available, in research quantity and in bulk. These precursors include: metal alkoxides, metal dialkylamides, metal b-dikelonates, metal carboxylates, organosilanes, colloidal solutions, and nanosize powders. Chemat also offers specialty sol-gel processing equipment which is professionally designed and manufactured with stringent quality control. In addition, Chemat manufactures customized processing equipment, including customized spin coaters and dip coaters, fabricated to the specific needs of customers.