High Speed Punching Rack Shelf Frame Metal Roll Forming Machine with 18 Stations - RH-RM-3200

High Speed Punching Rack Shelf Frame Metal Roll Forming Machine with 18 Stations For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale High Speed Punching Rack Shelf Frame Metal Roll Forming Machine with 18 Stations, Made in China, High Quality Products!, China cheap prodocuts, china suppliers Supplier, Manufacturer.

High Speed Punching Rack Shelf Frame Metal Roll Forming Machine with 18 Stations

?

?

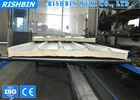

Structure of rack shelf frame roll forming machine

?

- - - -

Product Name | Main composition? |

Rack Shelf Frame Roll Forming Machine | Servo feeding system |

3 tons manually decoiler |

High speed punching machine |

Forming roller |

Chain driven transmission |

Main frame (including guiding platform) |

Hydraulic system |

Cutting device |

Electric controlling system? |

Stacker |

- - - -

?

?

Main data of rack shelf frame roll forming machine

?

- - - -

Name | Item | Description |

Rack Shelf Frame Machine | Number of stations | 18 stations |

Forming speed | 10-15m/min |

Shaft material | Using high-quality steel 45 quenched and tempered after finishing treatment |

Power of hydraulic station | 5.5kw |

Roller material | High quality 45 Forged chrome-plated hardware |

Power of main motor | 11.0kw |

Shaft diameter | 80mm |

Hydraulic station pressure | 10~12 Mpa |

Cutter material | Cr12 quenched |

Weight of high speed punching machine | 80 tons |

Electronic controlling system | Full-frequency PLC controlling system, error of cutting length ≤ 2mm |

- - - -

?

?

Main character?of rack shelf frame roll forming machine

?

1. Simple structure,good appearance since the whole machine is used profiled steel structure and wholly manufacturing after welding, in order to make it running stable and reliable.

2. Completely automatic cutting, accurate length and position, trim cutting for rear of profile sheets, no deformation.

3. Easy installation, good performance for manufacturing in factory.

4. Low noise, high efficiency.

?

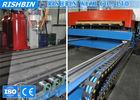

Working ?process

?

Coil loading → servo feed-in (sheet metal is put by guiding platform) → straightening→ high speed holes punching → forming → hydraulic cutting → stacker

?

Production line sketch

?

?

Warranty

?

The whole equipment including all the components will be guaranteed within one year except improper use.

?

?

Company introduction

?

Rishbin?was founded in 1999. With more than ten years& acute; development, now it becomes a leading professional supplier in the field of?roll forming machinery?industry, and exports its quality production?

line to the markets all over the world.

?

We?are?one?of?the?leading?suppliers?and?manufacturer?in?china?and?have?been?supplying?and?making?roll?forming?equipment?for?the?metal?building?construction?industry?for?a?long?time.

?

?

Contact us

?

For more information, please feel free to contact with us.

?

Skype: sarahrishbin

Mobile: +86-18118899986

E-mail: sarahrishbin@gmail.com

?

?

RISHBIN WUXI CO., LTD

Address: No. 10, Changjiang Rd, Wuxi, Jiangsu, China, 214000

Tel: 86-510-85853379

Welcome to Rishbin, an innovative supplier in roll forming machinery markets.

Rishbin was founded in 1999. With more than ten years' development, now it becomes a leading professional supplier in the field of roll forming machinery industry, and exports its quality production line to the markets all over the world.

Find below what we are working as and what we are able to provide:

1) Supplier (manufacturer and exporter): The most thing we take pride in is, with many years鈥?experience in exporting to overseas markets, Rishbin has built a very good business relationship and wide connections with hundreds of quality manufacturers in China, which has covered many kinds of roll forming machinery. In 2005, Rishbin built its own manufacturing plant in Wuxi, Jiangsu Province, which improves its function as not only a trading house but also a professional manufacturer.