GT- series drum screen for gravel grading - GTS

GT- series drum screen for gravel grading For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale GT- series drum screen for gravel grading, Made in China, High Quality Products!, China drum screen, GT- series drum screen Supplier, Manufacturer.

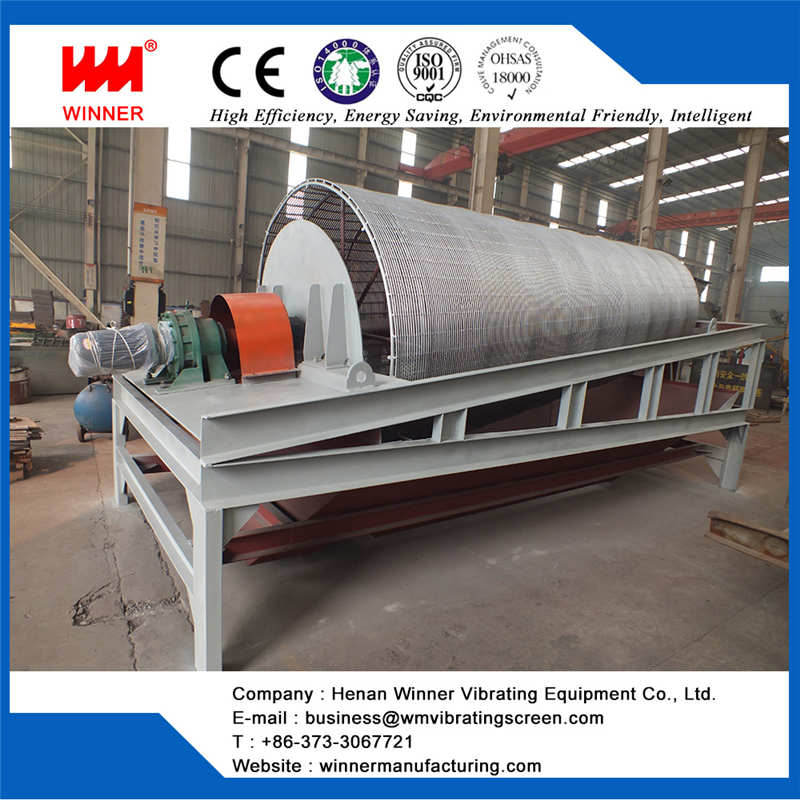

GT- series drum screen for gravel grading

Product overview of GT- series drum screen for gravel grading:

GT- series drum screen for gravel grading is a kind of machines for the power plant, coking plant, building materials, metallurgy, chemical, mining and other industries and developed a special screening equipment, which overcomes the circular vibrating screen and linear sieve in the screening than the wet material clogging problem, improve the screening system yield and reliability, by the majority of users praise.

The drum screen is made up of five parts: a hexagonal roller, a machine frame, a hopper, a speed reducer and an electric motor. Broken stone into the drum, by the centrifugal force of the drum rotation and the role of the jig screening materials. One by one through various mesh sieve sieve out. Different specifications of the stone out of the screen after the funnel into the belt conveyor to the finished material. On the one hand with the rotation of the rollers is screened by the centrifugal force of the drum rotation and the role of the jig screening materials. A large particle size of the stone along the slope of the drum forward flow through the sieve of different mesh is gradually screened. The small stone to sieve out into the funnel, and then by artificial shipped or their sent to the finished pile.

Working principle of GT- series drum screen for gravel grading:

GT- series drum screen for gravel grading is mainly composed of motor, reducer, roller device, frame, sealing cover, inlet and outlet. The roller device is installed on the machine frame. The motor is connected with the roller device through a coupling through a speed reducer, and the driving roller device rotates around the axis.

Henan Winner Vibrating Equipment Co., Ltd.

Address: Hongtai road, Xinxiang, State, China, 453700

Tel: 3733067721

Winner Vibrating Equipment Co.,Ltd, focuses on researching and designing of high efficiency, energy saving, environmental friendly vibration equipments from 1954.Now we have 60 years professional experience in the production of vibration equipment, including research and development, design,manufacture, sales and installation of the equipment for screening and sorting.

Our continuous development motivation is "To be the first-class screening expert in the world, to return our world green".

Winner Vibrating Equipment Co.,Ltd, ranks the top three in the domestic screening industry, and is a national high-tech enterprise. It has won the well-known trademark in the screening technology industry in China.

Henan Winner Vibrating Equipment Co.,Ltd covers an area of 110,000 square meters, well-equipped with advanced equipments.Our factory mainly has about 432 sets production equipments, including arc welding robot, spectrum analyzer, CNC plasma cutting machine, wear testing machine, hydraulic lifting platform, explosion-proof electric control box and so on.

The main products of Winner are complete sets of equipment for green steel, clean coal technology, clean power generation, food and medicine, fine chemical industry, disposal of the construction waste and living garbage, sewage sludge treatment, solid waste recycling.

Its R & D team has more than 100 people, focusing on high efficiency, energy saving, environmental protection products research and development and design. The new products are high efficiency and energy saving. The company also according to the different direction of R & D, has set up the engineering equipment research and development center in Beijing, the solid waste utilization research center in Shanghai, the garbage disposal equipment research and development center in Zhengzhou, the light matter sorting and domestic waste disposal research and development center in Xinxiang. Winner can ensure the customization and flexible manufacturing.