Galvanized layer ringlock scaffolding roll forming machine - cnzt-002

Galvanized layer ringlock scaffolding roll forming machine For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Galvanized layer ringlock scaffolding roll forming machine, Made in China, High Quality Products!, China Galvanized Layer Ringlock Scaffolding Machine, Roll Forming Machine Supplier, Manufacturer.

Galvanized layer ringlock scaffolding roll forming machine

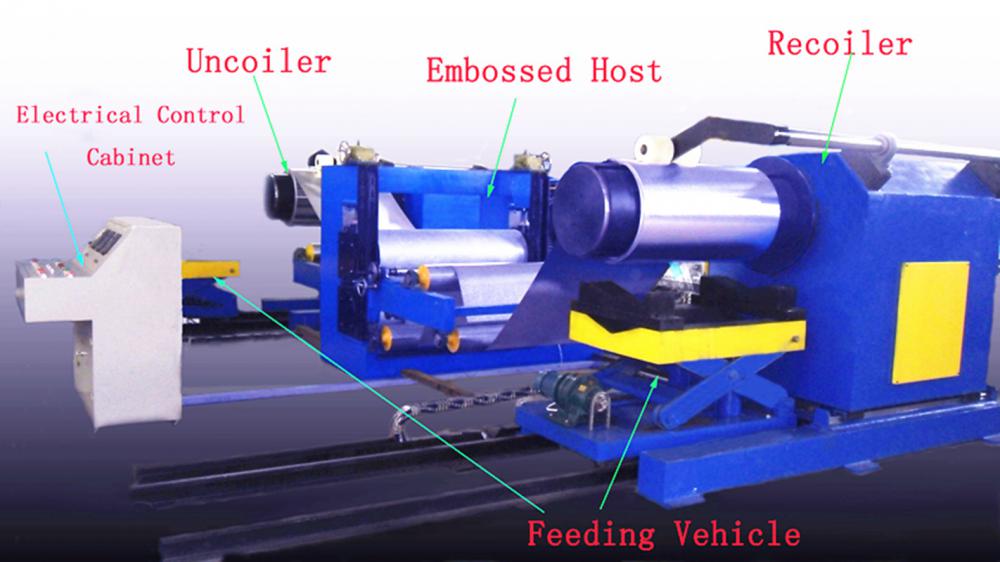

Galvanized layer ringlock scaffolding roll forming machine consists of automatic decoiler, the guide and leveling, continuous punching device, forming part, length cutting portion, receiving station, electrical control cabinets and other components.

Advantage of our Galvanized layer ringlock scaffolding roll forming machine:

1. Rollforming Mills For Scaffolding Springboards is controlled by PLC control system ,during normal work,it will more security.

2. The basic of Scaffolding Board Making Machine is middle plate,it will be welded and tempering to avoid the distortion.

3.The frame of machine is iron structure,it will tempering.After this process, it will more strong and long life.

4.Transmission structure for the gear box. Each rack has a gear box molding can ensure that equipment over time, high-intensity running, and long service life.

Basic information of Galvanized layer ringlock scaffolding roll forming machine:

1,Working speed :2-8 m/min

2,Material thickness :1.0-1.2mm

3,Control system:PLC

4,Decoiler :5T

5,Punching :one set

6,Main roll forming rollers:16row rollers

7,Roll material:GCR15 Steel after quenching process HRC58-62℃,he chrome plating surface treatment

8,Material of the shaft and the shaft diameter:45# steel processing, shaft diameter is 70mm

9,Main machine power :18.5kw

10,Hydraulic station power:5.5kw

11,Hydraulic pressure:24Mpa

12,Scissors punching material:Cr12Mov,Quenching HRC 58-62℃

13,Length tolerance:3m±1.0mm

14,Voltage :380V, 50HZ,3 phrase

15,driving mode :chain driving mode

16,Machine size :16.5*2.2*1.6m

17,Delivery date :30 working days

Accessories:

1.Easy damaged parts: conk 2 pcs, fuse-link 4 pcs

2. Rubber mat 1 pcs; 3.Bolt spanner 1 pcs

19,Payment terms: Payment: 30% T/T in advance and balance 70% after, Inspection confirmation before shipment.

Delivery: within 45 working days after receipt of deposit

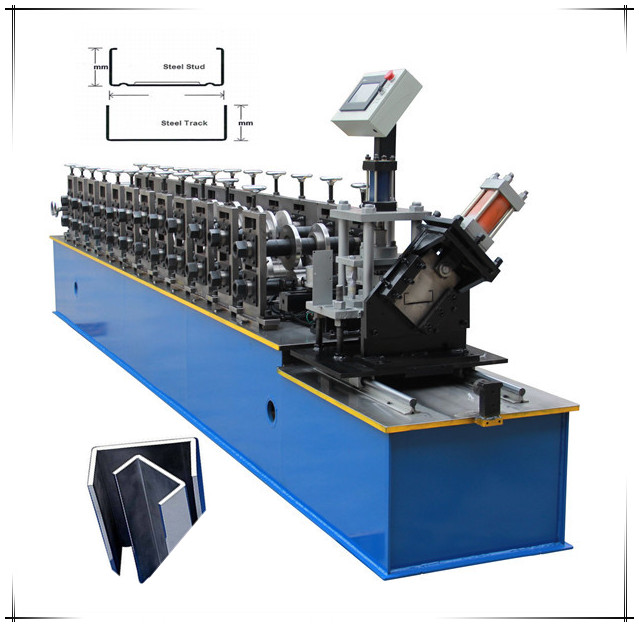

Detail introduction of each part: A profile drawing as reference:

Feeding and punching:

Roll forming for Rollforming Mills For Scaffolding Springboards:

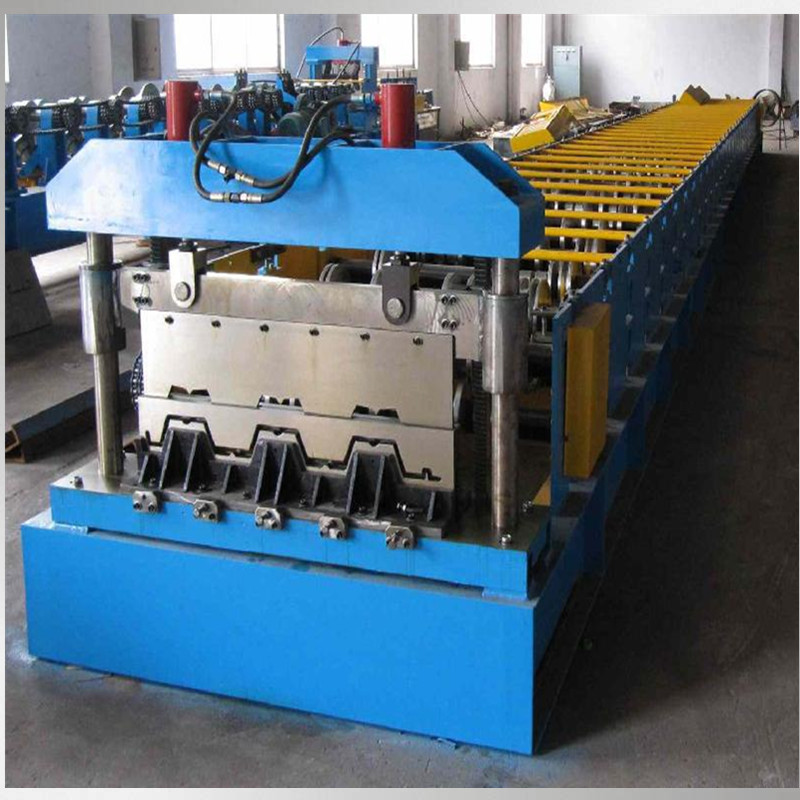

Cutting part:

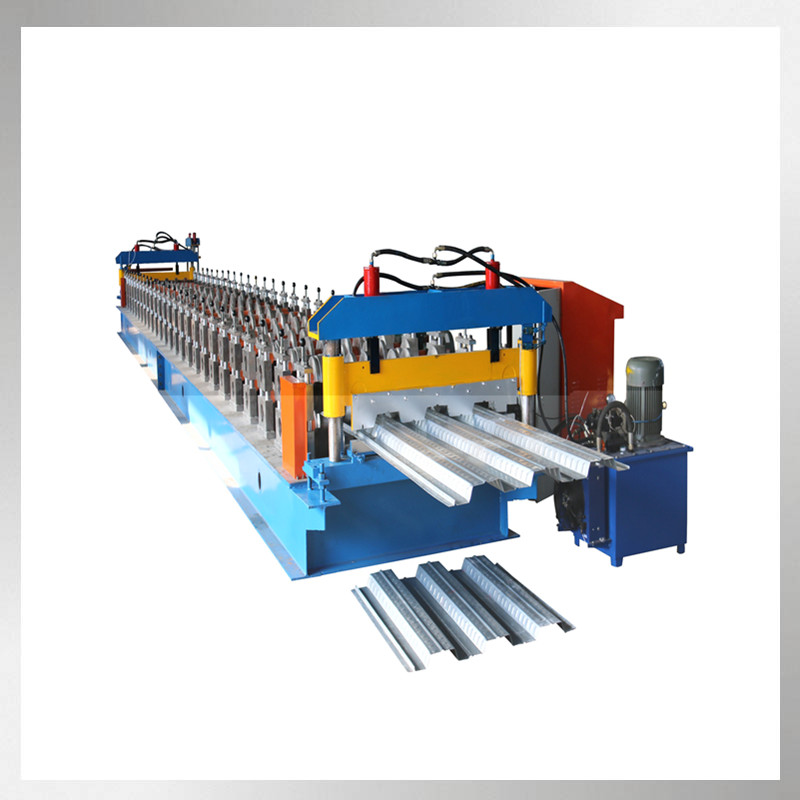

The final product of Scaffolding Springboards for you reference:

Cangzhou Zhongtuo cold bending forming equipment manufacturing co., LTD

Address: Room 807, Building 6, Taida International,Yunhe district, Cangzhou City, Hebei province, China , Cangzhou, Hebei, China,

Tel: 0086-317-2191158

Cangzhou Zhongtuo cold bending forming equipment manufacturing co., LTD from 1996. We are specialized in manufacturing color steel forming machine,light keel machine,C&Z purlin machine,Glazed tile forming machine,welded tube mill, stone coated roof production line,steel structural floor panel roll forming machine and so on. We also have the derivatives and raw material. We real provide you one station, non-stop service,Now,our machine have been exported to 30 countries,such as Canada,South Korea,Russia,Holland,Sri Lanka,Malaysia,India,Brazil,etc.Our company insists on the service aim: Quality First,Credit First. We believe that we can make the future cooperation and achieve win-win.

http://www.rollsformingmachines.com

http://www.rollsformingmachines.com