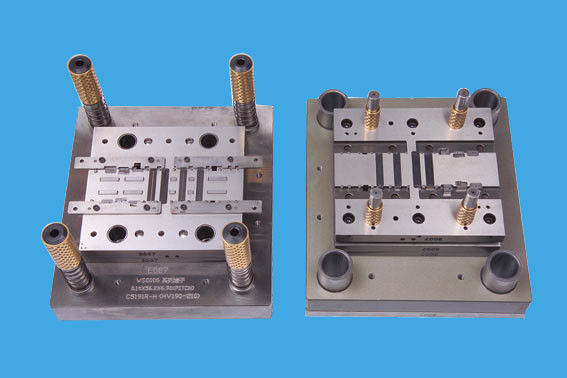

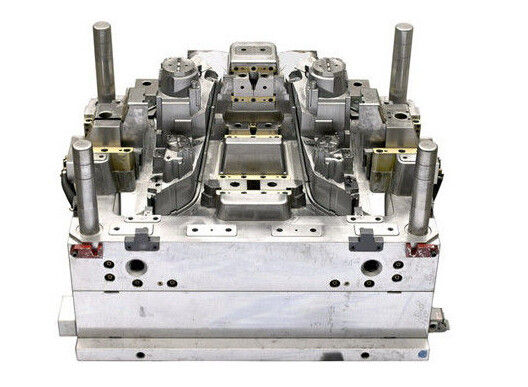

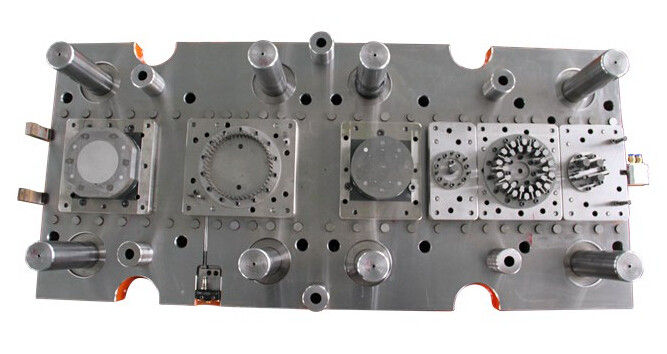

Flat Blanking Auto Spare Part Metal Stamping Molds , Progressive Stamping Die - AIA-1

Flat Blanking Auto Spare Part Metal Stamping Molds , Progressive Stamping Die For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Flat Blanking Auto Spare Part Metal Stamping Molds , Progressive Stamping Die, Made in China, High Quality Products!, China cheap prodocuts, china suppliers Supplier, Manufacturer.

Flat Blanking Auto Spare Part Metal Stamping Molds , Progressive Stamping Die

?

Product Description:

?

Mould details:?

1. Design 3D drawing for customers& acute; confirmation according to their 2D drawning or sample when placing to order.?

2. Mould Matieral: Different grade: P20, S136, 2316, H13, etc.?

3. Surface treatment: ?mirror polish, polish, texture

4. Independent temperature control & heating system Which boasts an even heating temperature and keeps product with reliable and stable quality.?

5. Mould life: ?more than 1 million shots

All inserts can be interchangable.?

6. Product matieral: ABS, PC, PE, PMMA, POM, PP, PBT, PSU, PVC, PA6, PA66+GF,ect

7. Quick deliver time: 25-60 days

?

- - - -

Item | Description |

Core steel | MovCr12, P20, H13, 718, 2738, NAk80, S136, SKd61 .etc |

Mould base | LKM, HASCO? , DME. ect |

Mould cavity | Single/Multi |

Runner | Cold /Hot |

Mould design | 2D/3D design |

Design software | CAD/CAM/PRO/E,SOLIDWORKS.UG |

Mould proceesing | CNC wire cutting/ EDM/Sparking/Planer/Grinder machine etc. |

Injection gate | Sprue gate/pinpoint gate/Edge gate/Disk gate/Ring gate/Submarine gate. etc |

Raw plastic material | ABS,PC/ABS,PA,PPS,POM,PBT,PC.etc |

Mould life | Around 100,0000?shots |

Mould cavity processing | Grossy polising/Texture/Plating/Coating/Semi gross surface.etc |

Ejection system | Pin Eject/ Plate eject /Air eject .etc |

Injection Cycle time | 2-5 shots per minute |

Payment item | 50% of Deposit by T/T , the balance 50% paid by T/T against the Moulded samples comfirmed |

Delivery time | 30 - 60 days |

Special requirement | Depend on the customers |

- - - -

?

?

Competitive Advantage:

Why choose JTH?

?

a,?All of our products would be produced by strict control in every machining process.

b, We can offer you very low price and best after-sales service in order to promote our big and long cooperation.

c, We can offer you the one-stop solution from 3D design to product forming and we also provide the mould components during the mould lifetime.

d, We have always carried out the human-based management, so everyone would be always responsible to their own work.

e, We have owned experienced engineer in the mould department and mold injection department and then we can provide not only mould but also products.

f, Our principle is customer is the God, Be committed to the continuous improvement of our product quality, to meet customer need as much as possible.

if you think we can cooperate, pls send us your 3D drawing or weight&size details, we will reply you immediately. We are sure can be efficient supplier for your business partner in the future. Thanks.

?Welcome your inquiry and cooperation. We are ready to offer our excellent service for you

Jintaihua Precision Molds Co.,Ld

Address: China guangdong shenzhen baoan district, Shenzhen, Guangdong, China, 518000

Tel: 86-135-90287963

Shenzhen Jin Taihua metal products co., LTD. Was established in June 2000, is located in baoan shajing xinqiao furong industrial zone, convenient transportation and superior geographical environment, is a professional engaged in precision metal mold design and production, metal stamping products, accessories, all kinds of oven door buckle, locks and chassis cabinets manufacturing, precision machinery parts processing, non-standard equipment design and manufacture of professional manufacturers. Now has complete production with the CNC computer gongs, computer lathe, automatic lathe, CNC milling machine, surface grinding machine, shearing machine, bending machine, line cutting machine, 16 t - 100 t punching machines and other processing equipment more than 80, the company factory building area of more than 1800 square meters, more than 100 employees, including research and development and technical personnel for 3 people, quality management personnel 8 people, production and technical personnel account for five people. Insist on development, innovation, quality, service, good faith for the company development.