Fire Resistant Two Layer PU Sandwich Panel Production Line with Fly Saw Cutting - RH-PU-125

Fire Resistant Two Layer PU Sandwich Panel Production Line with Fly Saw Cutting For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Fire Resistant Two Layer PU Sandwich Panel Production Line with Fly Saw Cutting, Made in China, High Quality Products!, China cheap prodocuts, china suppliers Supplier, Manufacturer.

?

Fire Resistant Two Layer PU Sandwich Panel Production Line with Fly Saw Cutting?

?

?

Composition?of Two Layer?PU sandwich panel production line

?

1.?Decoiler???

2.?Upper?and?lower?forming?machine??

3.?Pre-heating?table???

4.?Reaction?injection?machine?

5.Side?chemical?sealing?installation???

6.?Double-belt?laminator?

7.?Hot-air?circulator???

8.?Non?–stop?cutter?

9.?Run?out?table

?

?

Specifications of?Two Layer?PU sandwich panel production line

?

- - - -

Coil?Material? | Thickness | 0.3mm-0.8mm?????????????????????????????????? |

Coil?width | Depend?on?customer’s?requires |

Yield?Strength | 250-550Mpa |

Material | Color?steel,?galvanized?steel????????????????????? |

Decoiler?/?Uncoiler | Coil?Width???????????????????????????????? | Max.?1250mm |

I.D | 510mm-610mm |

O.D | Max.?1300mm |

Capability | Max.?8Tons |

Decoiler?type | Manual?/?Hydraulic/Automatic |

Feeding?&?guiding | Pinch?feeding | 2?Rollers? |

guiding | 2?Rollers? |

Cutting?device | Cutting?motion | Cutting?adopts?tracking?cutting |

and?saw?(or?fly?saw)?of?the?cutting?machine?can ?move?transversely?1500mm,?Cutting?machine? moves?longitudinally?and?transversely?along? the?slide?way |

Cutting?machine?adopts?one-side?blade?band? saw?manner,cutting?and?revolving?after?cutting.? The?cutting?saw?can?revolve,?so?cutting?in?two ?directions?is?realizable |

Cutting?Tolerance | +/-1.5mm(per?3m) |

PU?sandwich?panel? | thickness | 25-100mm |

Standard?Sandwich?Panel?Size | max1100mm?x?4000mm(Width?x?Length) |

Linear?Speed?of?production | 2-5?m/min |

Reciprocating?times?of? injection?head?per?minute | <60 |

Control?system | Production?type:?totally?continuous?production? with?PLC?controlling |

Roll?Forming?Machine | Forming?Stations | ABOUT?18-24steps |

Roller?material?? | 45#?steel,?heat?treatment?????????? |

Diameter?of?shaft | 75mm |

Shaft?material | High?grade?45#?steel |

Drive?type | By?chains |

Main?power | 7.5kw |

Electrical?control | Operation?type | Touch?screen?&?Button |

Runout?Table | Function | To?support?the?finished?panels |

- - - -

?

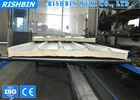

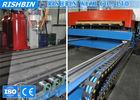

Reference picture

?

?

Applications:

?

These?sandwich?panels?are?mostly?used?for?industrial?purpose,?these?are?very?light?weight?but?can?bear?

very?heavy?load.?It?also?reduces?the?heat?inside?the?building.?

?

With?a?wide?range?of?different?colors,?available?in?cut-to-length?supply?and?ready-to-install,?

this?modern?building?product?takes?a?good?share?in?a?highly?economic,?weather-independent?and?fast,?

modular?building?process.

Beside?the?extremely?high?thermal-insulation?values?of?the?polyurethane-core,the?panels?create?

a?high?overall?stiffness?with?their?& quot;composite& quot;?function?and?therefore?support?very?good?statically?values.

?

?

Advantages?

?????Light?weight:?10~?14?kg/m2and?hence?reduced?steel?frameworks?and?system?can?become?economical.

?????Good?thermal?insulation,?with?average?coefficient?of?thermal?conductivity?is?0.018?~?0.020?W/mk.

?????Available?in?customized?length.?And?in?wide?range?of?colors.

?????Cold?and?heat?resistance:?Perfect?temperature?resistance?deformation?from?-110o?C?to?120o?C.

?????Great?energy?saver?and?hence?indispensable?in?air-conditioned,?cooled?and?heated?buildings.?

?????Virtually?zero?maintenance?throughout?life.

?????Installation?is?convenient?and?Flexible;?not?requiring?large- ? ? ? scale?lifting???devices,?and?thus?lowering?building?costs.?

?????High?intensity?and?large?rigidity?ensures?suitability?for?weight-bearing?structures?and?for?supporting?and?protective?structures.?

?????Non-water?absorbent.?

?????Environmentally?friendly.?And?bring?down?life?cycle?cost?for?any?built?environment.

?

?

Contact us

?

For more information, please contact us freely.

?

Skype: sarahrishbin

Mobile: +86-18118899986

E-mail: sarahrishbin@gmail.com

RISHBIN WUXI CO., LTD

Address: No. 10, Changjiang Rd, Wuxi, Jiangsu, China, 214000

Tel: 86-510-85853379

Welcome to Rishbin, an innovative supplier in roll forming machinery markets.

Rishbin was founded in 1999. With more than ten years' development, now it becomes a leading professional supplier in the field of roll forming machinery industry, and exports its quality production line to the markets all over the world.

Find below what we are working as and what we are able to provide:

1) Supplier (manufacturer and exporter): The most thing we take pride in is, with many years鈥?experience in exporting to overseas markets, Rishbin has built a very good business relationship and wide connections with hundreds of quality manufacturers in China, which has covered many kinds of roll forming machinery. In 2005, Rishbin built its own manufacturing plant in Wuxi, Jiangsu Province, which improves its function as not only a trading house but also a professional manufacturer.