Filter Disc - FD01

Filter Disc For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Filter Disc, Made in China, High Quality Products!, China Filter disc, extruder screen Supplier, Manufacturer.

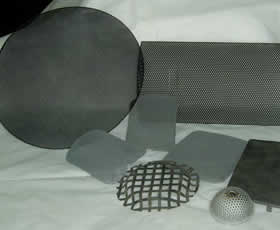

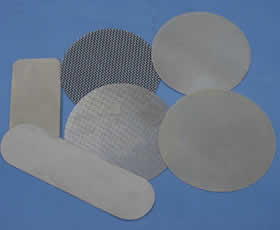

Filter discs can be made of woven wire mesh, sintered fiber web or sintered wire cloth sheets while woven wire mesh filter discs are the most popular one.

Filter discs made of woven wire mesh are available in a wide range of materials, sizes, shapes, micron retentions and configurations.

Materials: Stainless steel, carbon steel, brass, etc.

Shapes: Circles, kidney, and rectangular.

Filtration Rating: 12 to 1,000 microns.

Layers: Single layer or spot welded Multi-layer screen discs.

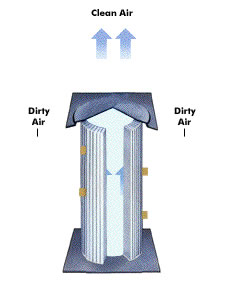

The Disc Filters belong to the side feed group and have been around for many years. They are generally used in heavy duty applications such as the dewatering of iron ore taconite, hematite, coal, aluminum hydrate, copper concentrate, pyrite flotation concentrates and other beneficiation processes. The high time for Disc Filters was in the 60& acute;s when the metallurgical industries were booming and filters with 300 m2 and larger were manufactured.

The filter consists of several discs, up to 15 in the larger machines, each made up from sectors which are clamped together to form the disc. The sectors are ribbed towards the neck and designed for a high capacity drainage rate. One of the main features is that the required floor space taken up by disc filters is minimal and the cost per m2 of filtration area is the lowest when compared to other vacuum filters.

Anping Wingle Filter Element Factory

Address: 78 Jianan street, Anping, Hebei, China., Anping, Hebei, China, 053600

Tel: +86-318-38642227

Wingle manufactures the following types of filter elements:

Hydraulic, designed to equip pressurized filters, filter drain and other hydraulic systems.

Oil intended for lubricating systems, filters, complete machines and mechanisms in various industries.

Fuel intended for the complete fuel filters vehicle engines.

Aircraft designed for air filter assembly vehicle engines and compressors.

Filter elements are manufactured with a nominal fineness of filtration:

- Paper - 05,10,25 and 40 microns

- Net - 40, 80.120 and 160 microns

Filter elements provide the highest degree of filtration efficiency for industrial, mobile, and process applications. Our filter elements are composed of micro-glass media, the most recent innovation in high performance filtration technology. Micro-glass media is inert, inorganic, and far exceeds any paper or cellulose filter element performance. Water or chemicals, which cause softening, swelling, and degradation in conventional cellulose or pleated paper filters, do not affect micro-glass media.

The advantages of making filter element:

Filter elements and filters manufactured have a high technical specification through a number of structural and technological features, chief among them the use of modern materials quality, reliability and stability of the design process.

The use of modern filter materials:

Effective is the one filter element, which not only removes dirt but keeps them securely for the duration of the service. Depending on the material of the filter elements are divided into two main groups: surface and volume. use of filter material has been a very stable structure. Enhanced binding of the fibers provides a stable bond between the fibers and increases the strength of the material under the influence of load versus load fluctuations of pressure and flow rate, temperature and aging. With this filter elements maintain its high performance during its entire life.