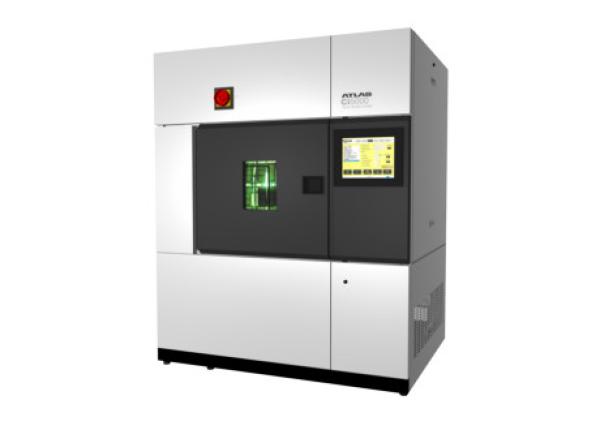

Dynamic Seam Fatigue Tester

The sewn seam dynamic fatigue testing machine is designed to evaluate the fatigue resistance of seam on the material which is applied on the surface of automotive seat. The surface material of car seat (leather, synthetic leather, fabric, etc.) is often stitched together. The stitching strength of the material seam and the fatigue strength of the seam can directly affect the service life of the seat. The strength and life of the joint of the test material can effectively predict the life of the seat and provide the direction of improving the service life.

The Seam Fatigue Tester is a two station bench top machine, used for evaluating fabric or leather seating materials resistance to tearing or needle hole elongation of a sewn seam. Each station includes a pair of suitable clamps for attaching the test sample. A height gage is used to set the sample clamp separation distance of the 140mm for each station.One or two stations can be tested at a time.