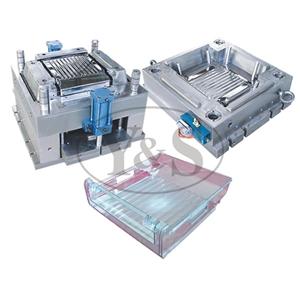

Cutlery Mould - No.1-1

Cutlery Mould For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Cutlery Mould, Made in China, High Quality Products!, China Cutlery Mould,Thin Wall Mould, Supplier, Manufacturer.

Mould name:cutlery mould?Shaping Mode:Injection MouldDisposable cutlery mold, Packaged cutlery mould, Packaged cutlery mold, Disposable cutlery mould, cutlery moldThin wall mold because of its thin wall, light products, high yield, short turnaround time reasons, so the mold production requires a very high clamping structure to be reasonable, the concentricity of the product is higher, not eccentric is not misplaced, waterway design should be reasonable, so as to reduce the molding cycle can yield up to 5 seconds per mold, a mold cavity 4, draft angle to be reasonable, to prevent deformation and die sticking out the top.step1, the sealing surface of the design with zero zero.2, the cartridge body and lid mating surfaces of the air gap 0.15-0.2mm3, the edge of the lid and box body fit at design time and space around 0.8-1mm, specifically to see the product size. 4. The rib design is generally thinner than the products that thin products mostly transparent material, thick tendons prone to bubbles4, the shape of the product is simple, there is no upside down and touch the perforation, similar cups, 3 degrees above the surface of the product can be designed into a gas side, oblique gas, valve, etc.5, the stripper plate rib height 1mm or less, in order to process this rib-bit, the stripper plate can insert up. 3. The multi-cavity mold design methods: (1) Independent Self-locking: multi-cavity independent self-locking fit all shapes thin wall mold design, each independent chamber, the core bottom clamping surface species into the core complex boards. (2) the overall clamping: wall thickness greater than 0.8mm, the machine is relatively small, difficult place to go, with the overall structure, but must explain in advance6, cavity, core design: (1), the complex cavity plate generally use S136 steel. (2), the bottom of the barrel type structure single-chamber cavity is empty, press board must ensure that there is 45mm more than the height of the steel material. Prevent caviti

Get QuoteTAIZHOU HUANGYAN YUESEN PLASTIC MOULD CO,LTD

Address: No 32 KongXin Avenue, XinQian development zone, Huangyan district, Taizhou City, taizhou, zhejiang, China, 318020

Tel: 86-576-84217252

Taizhou Huangyan Yuesen Mould CO., LTD. has strict quality control system and high efficiency work team. We specialize in manufacturing plastic injection mould which covers a great range,Website:http://yuesenmold.com/, including autoparts, commodity, household appliances, vehicle, baby products, garden products & customized parts.

The Plant is well equipped with the latest machines and can cater to all kinds of requirements of the injection plastic moulds. We set up perfect CAD/CAM/CAE system and we also believe in learning at a day to day basis and upgrade our facilities to be able to provide a better future for our customers.

We own a whole set of advanced mould processing system, sophisticated equipment and professional workers who have high efficiency service consciousness. We wish to provide the best service at all times at minimum cost which is the guiding Motto of the company.

Be confident with our quality, service and price, we keep long term business relation with our clients from USA, Argentina, Dubai, Spain, Syria, Italy, Korea, Brazil, Slovakia and Turkey.

We received a high evaluation and recognition of our customers.We are warmly and sincerely looking forward to your visit and cooperation.

http://yuesenmold.com/