Customised Cr-Mo Alloy Steel Liners Wear Resistant Casting For France Alstom - DF089

Customised Cr-Mo Alloy Steel Liners Wear Resistant Casting For France Alstom For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Customised Cr-Mo Alloy Steel Liners Wear Resistant Casting For France Alstom, Made in China, High Quality Products!, China cheap prodocuts, china suppliers Supplier, Manufacturer.

?

Customised Cr-Mo Alloy Steel Liners Wear Resistant Casting For France Alstom?

?

Quick Details

Materials: Double-Media Quenching Chromium-Molybdenum Alloy Steel Series.

?

Cr-Mo Alloy Steel Liners?Description:

A. They are series of wear material which we design specially for ball mill liners in coal-fired power plants, mines and cement plants.

B. With our special double-media quenching process, the material can not only achieve ideal hardness (HRC48~55) but also ideal toughness value (AK30~100J).

C. It can completely meet the requirement of liners of large and middle-size ball mills at home and abroad. The match of Middle Chrome Liners and High Chrome Cast Balls has been the typical model in coal mills and cement mills.

D. Meanwhile, the material is applicable to the teeth plates, armored plates and hammers of crushers and excavator bucket teeth.

China wear resistant casting supplier provides stainless steel casting services to worldwide steel casting customer. Hope you find our castings steel process and wear resistant castings product description helpful.

?

In the recent 20 years, our liners have been widely used in large, medium and small ball mills in Chinese power generation, mining, cement, Chemical engineering and metallurgical industries and super fine pulverizing equipments. It is the only recommended liner product in the latest standard of the electric-power industry in China.

?

Technical Parameters

Wuxi Orient Anti-wear Engineering Co., Ltd.

Chemical Composition & Mechanical Property of Wear-resistant Castings

- - - -

Item | Cr-Mo Alloy Steel I | Cr-Mo Alloy Steel II | Cr-Mo Alloy Steel III | High Cr white iron | High Cr Alloy Steel | High Manganese Steel | Ni-Hard cast iron |

C | 0.30~0.50 | 0.65~0.90 | 0.40~0.90 | 2.40~3.20 | 1.1~2.2 | 0.90~1.30 | 2.40~3.60 |

Si | 0.50~1.20 | ≤0.75 | 0.70~1.20 | 0.60~1.20 | 0.60~1.20 | ≤0.08 | ≤0.80 |

Mn | 0.40~1.20 | 0.50~1.20 | 0.60~1.00 | 0.50~1.00 | 0.50~1.00 | 11.00~18.00 | ≤2.0 |

Cr | 1.70~2.50 | 1.50~2.50 | 4.00~7.00 | 12.00~30.00 | 11.00~30.00 | 1.50~2.50 | 1.5~10 |

S | ≤0.04 | ≤0.06 | ≤0.04 | ≤0.04 | ≤0.04 | ≤0.04 | ≤0.15 |

P | ≤0.04 | ≤0.06 | ≤0.06 | ≤0.06 | ≤0.06 | ≤0.06 | ≤0.15 |

Mo | ≤0.5 | ≤0.5 | ≤0.5 | 0.10~3.0 | 0.10~3.0 | ≤1.0 | ≤0.10 |

Cu | 0.10~0.60 | ≤0.25 | 0.20~0.40 | 0.10~1.00 | 0.10~1.00 | - | - |

Ni | ≤0.50 | ≤0.30 | 0~0.30 | 0~0.30 | 0~0.30 | - | 3.3~10 |

Re | ≤0.02 | ≤0.02 | ≤0.02 | - | - | - | - |

Equivalent Specifications | DL/T 681-1999 ? GB/T26651-2011 | AS 2074 L2B Mod | DL/T 681-1999 | GB/T 8263-1999 AS 2027 Cr27 AS 2027 CrMo 15/3 AS 2027 CrMo 20/2/1 ASTM A532 Class III type A 25% Cr ASTM A532Class II type B 15% Cr-Mo BS 4844 3E DIN1695 NFA32401. | GB/T 5680-1998 DL/T 681-1999 JIS G 5153-1999 ASTM A 128 DIN GX120Mn12 AFNOR:Z120Mn12 | GB/T 8263-1999 AS 2027/Ni-Cr1-550 AS 2027/Ni-Cr2-500 AS 2027/Ni-Cr4-500 AS 2027/Ni-Cr4-600 AS 2027/Ni-Cr4-630 ASTM A 532 1-A,B,C,D ASTM A 532 2-A,B,C,D,E ASTM A 532 3-A |

Material Type | Martensite Steel | Martensite or Pearlitic Cr Mo Steel | Martensite Steel | Martensite matrix | Austenitic Mn Steel | - |

Hardness | HRc≥48 | HB470 & HB 321~370 | HRc≥50 | HRc≥56 | HB≤300 | HRc≥56 |

Impact Value | Ak≥40J | - | Ak≥10J | Ak≥4J | Ak≥80J | - |

- - - -

?

Our foundry has complete melting, heat treatment and test equipments, such as mid-frequency induction electrical furnaces, quenching and tempering furnaces, blast shot, spectrometer, Rockwell and Brinell Hardness tester, impactor, UT tester and metallographic microscope. We achieved the certificate of quality management system ISO 9001:2008. We have been exporting castings to oversea markets, such as Brazil, Australia and South Africa.

?

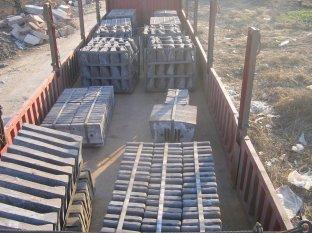

Foundry Photo

?

Wuxi Orient Anti-wear Engineering Co.,Ltd

Address: Zhongyao,Xishan District, Wuxi, 214000, Jiangsu, China, Wuxi, Jiangsu, China, 214000

Tel: 86-510-88791954

High Chrome white iron we can produce include 15Cr, 18Cr, 20Cr and 26Cr. Under same working condition, the wearperformance of High Chrome mill liners is four times of that of high manganese steel liners and twice of that of low Chrome alloy steel liners.