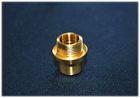

Complexity Customize CNC Milling Parts for Automation Industry Tolerances +/- 0.005mm - CMAP

Complexity Customize CNC Milling Parts for Automation Industry Tolerances +/- 0.005mm For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Complexity Customize CNC Milling Parts for Automation Industry Tolerances +/- 0.005mm, Made in China, High Quality Products!, China cheap prodocuts, china suppliers Supplier, Manufacturer.

Complexity Customize High Precision CNC Milling Parts Of Aluminium Automation Industrial

?

?

Specifications:

- - - -

Technical Parameter for Complexity Customize High Precision CNC Milling Parts Of Aluminium Automation Industrial | Length x Width x High | 5X5 X5 mm ~ 500X500X500mm |

Tolerances | +/- 0.005mm |

Material use | Aluminium, Copper, Brass, Stainless Steel |

Processing | CNC Machining Center |

Surface Treatment | Galvanized, electro-plating, conversion coating,Zinc plating, or chrome plating available |

Surface Roughness | Ra0.4a |

Run-out | 0.005mm |

Flatness | 0.005mm |

Perpendicular | 0.005mm |

Cylindricity | 0.005mm |

- - - -

?

Description:

Hantech Precision-- Your Reliable Precision Parts Supplier

HanTech Precision group has been established since 2007, we are a professional providing customize and high precision machining parts.

With years experience in the manufacturing and servicing of CNC machining parts, customize or tailor made machining parts, Precision CNC machining service and die casting parts. We have been establishing a high reputation for our high quality as well as our service. We are able to provide a Total Solution services for our customers, starting from product design, material sourcing to finished products. HanTech Precision will work hand in hand with our customer who continuous looking for costs reduction and also fulfill their tight lead time. Our fundamental purpose is to ensure our customer satisfaction by providing first-class project management control and problem-free products.

?

- - - -

Our Winning strategy | # Providing value-added engineering service.# Assisting you from material choosing, structure testing, process, up to finished goods arrangement.# One-stop custom machining services. |

Total Solution Provider | # Service provide started from material sourcing, product design and finished products shipment, inclusive supply chain management (ODM/OEM). |

Competitive Advantage | # Top Quality# Competitive Price# On Time Delivery# Excellence Customer Service |

- - - -

?

Why choose HanTech Precision?

1. Strict Quality Control

HanTech Precision has been in CNC machining operation business for almost 10 years, We have trained ourselves and capable to provide high quality and tight tolerance precision machining parts service for worldwide customers. It is our commitment to deliver problem-free products and on time delivery. We understand the requirement for quality and accuracy in everyone project and parts. HanTech Precision will treat seriously for our customer& acute;s drawings and adheres to the industry standards strictly in our precision machining.

2. Effective and Efficient Project Management

A successful project will depend on a good management concept. All this includes effective of scheduling of the workflow, good communication internally and also with customer and good control of the manufacturing process.

We will assigned an experienced project engineers to the customer from initial to end until mass production. For each of the projects, we will review the entirely project starting from design stage and come out with the detailed DFM(design For Manufacturing) plan and also estimate the? progress schedule. During the manufacturing, our project engineer will follow up personally to ensure the project carried out smoothly and you can able to get the detailed information about the progress of each of the parts. This is the key point that we are adopt, transparency of project management and fast response to our customer. We will provide the report which is the detail information concerning the progress of the project from time to time or on the request of customer.

?

- - - -

Description | Types |

Material | # Brass Copper# Aluminium# Stainless Steel# Titanium# Carbon Steel# Plastic# Nyalon |

Surface Treatment | # Anodizing# Heat treatment# Chemical conversion coating# Plating(Zinc, Nickel, Gold, Silver, Chrome, Oxidize, etc) |

Process | # CNC Turning# CNC Milling# CNC Milling & Turning# Customize CNC Machining |

Application Industry | # Automotive# Automation# Instrument Industry# Telecommunication# Optical Communication# Aerospace# Machinery Equipment# Robotics |

- - - -

?

Customer Service:

At HanTech Precision, we are committed to meet all the requirements from our customer. Our customer service is based on effectiveness of two-way communication and a quality service to our customer is also the company wide goal. We value our customer feedback which we believe customers have valuable opinion to share with us.

In order to have an effective partnership with our customers, we ensure ourself that we are accessible to them before, during and after project is completed. We promise a close working relationship with our customer so that our customers can easily share with us of any concerns or queries they have. On top of this, we also stress on our internally communication, which is equally importance to our customer and this is also set as one of our service goals. An effective communication between the personnel involved in a project and our customer is crucial and also is our challenge to meet the project ahead and anticipating any problem that can be occurred and solve it! From prototype, design, assembly, as well as information sharing with customer, we are providing a total solution for our customer.

?

Service

HanTech Precision can provide one-stop precision machining service ?to our customers. Our precision machined parts are mostly used in the field like automotive, automation system, special purpose machinery, medical equipment,electronic ?equipment,fluid control,lighting industry, optical industry,model manufacturing,etc.

HanTech Precision provide a wide range of machining service using advanced equipments and latest technology including:

CNC Milling Service

CNC Turning Service

CNC Milling and Turning Multiple

Mechanical Parts Design

Precision Grinding

Auto-Lathing Turning

Die Casting

?

- - - -

Process | Axis | Capability |

# CNC Milling# CNC Milling# CNC milling-turning# Custom Machining | ?3 axis to 4 axis machine | ?Accuracy of holes : 0.005mm,

?Accuracy of dimension :0.005mm,

?Accuracy of center distance: 0.01mm |

- - - -

?

Quality

HanTech Precision always treat quality is the most important for manufacturing. To ensure high quality of our machined parts, we have detailed quality control system and equipped with most of the measuring equipments.

From incoming of raw material to finished products shipment, we will ensure every step is meeting to the customer& acute;s requirements. All the products will go through the below 4 steps to complete the whole manufacturing process:

Raw material inspection -> In processing inspection -> Final inspection -> Outgoing inspection

?

We are practice ISO9001:2008 and TS16949 in-house quality control system and these measuring equipments are to ensure problem-free products.

?

HanTech Precision Electronics Co., Ltd.

Address: N0:2, Yangxian Road, Suzhou Industry Park, Suzhou, Jiangsu, China, 215000

Tel: 86-512-80983758

Background

HanTech鈥檚 group is professional in CNC Precision Machining Parts. We are ISO9001 certified and also rewarded as Strategic Partner for Military Product from our customer. In order to enhance ourselves better, we are practicing ISO/TS16949 Automobile Standard in our operation, targeted to be certified by Q4 this year.

We are providing a Total Solution for Precision and Die-casting process for Automobile (Auto) / Automation, Telecommunication, Optical Communication, Aerospace, Medical, Electronic and Military industry.

HanTech鈥檚 professionals are all well trained, and prepared to work with customer for new product development, improvement and mass production. Due to our outstanding performance including in technology, price competitiveness, quality, and customer service in SuZhou City, JiangSu Province of China. As the result, we are proud to become the partners for those well-known companies in China, as well as the world famous automobile companies.