Cold Bend Forming Machine - No.1-1

Cold Bend Forming Machine For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Cold Bend Forming Machine, Made in China, High Quality Products!, China Cold Bend Forming Machine,Purlin Roll Forming Machines, Supplier, Manufacturer.

The profile drawing for Cold Bend Forming Machine?The thickness of Material: 1.5-3.0mm? ? ?Working flow:?Uncoiler--Feeding--Leveling--hydraulic punching--Hydraulic cutting--Roll forming--Output table??Character of main structure?for Cold Bend Forming Machine

? ?a) The structure?of the Cold Bend Forming Machine?is simple and the appearance of the Cold Bend Forming Machine is beautiful because we adopt the shape-steel structure and most of the connecter is screw which make the machine flexible and stronger.

? ?b) All the components of Cold Bend Forming Machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.

? ?c) We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming.

? ?d) Cold Bend Forming Machine is very easy to install the equipment and suitable for producing in the factory.

? ?e) Low noise with high efficiency ? ?f) The width of the profile can be automatic adjusted and the last 10 roller stations can be overturned ?to make C&Z purlin?Main Specification?of the Cold Bend Forming Machine ? ?A. 5T manual decoiler

? ?1) Capacity: 5ton

? ?2)Loading width: MAX 500mm

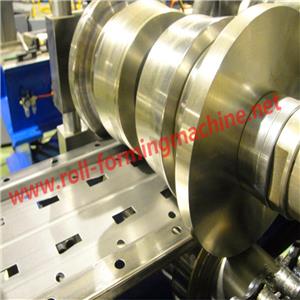

? ?3)Valid expanding range for coil inner diameter: 480-520mm ? ?B. Main roll forming system

? ?1)Main motor power: 15kw

? ?2)Feeding and leveling power: 4KW

? ?3) Hydraulic power:5.5KW

? ?4)Hydraulic pressure: 20Mpa

? ?5)Punching: Hydraulic pre-punching before forming,Website:http://www.roll-formingmachine.net,

? ?6)Punching mould:Cr12mov

? ?7)Cutting: Hydraulic pre-cutting before forming, Auto cutting when reach the set length.

? ?8)Cutting blade: Cr12mov

? ?9)Cutting tolerance: +/- 1.5mm

? ?10)Drive: Chain

? ?11)Roller material: Gcr15 steel and quench treatment hardness 58-62, chrome coated 0.05mm

? ?12)Leveling rollers: 7rollers(three upper and four lower)

? ?13)Roll station: 16groups

? ?14)Raw material: 1.5-3.0mm,pre-galvanized strip steel

JIANGYIN DINGBO TECHNOLOGY CO., LTD

Address: Xingyuan Rd. Beiguo, Gushan Town, Jiangyin City, JiangSu Province, China, Jiangyin, JiangSu, China, 214414

Tel: 86-510-86952128

JIANGYIN DING BO TECHNOLOGY CO.,LTD is聽a manufacturer specialized in customizing聽all kinds of roll forming machines. With our advanced techniques and experienced staff,Website:http://www.roll-formingmachine.net, we can produce simple profiles as well as complex components with precision tolerances. Most of our main production staff have more than聽10 years of experience,聽which聽ensure good machine quality聽and high values for our customers.

Advantages of聽Our聽Roll Forming聽Machine:

Roll formed parts can have a variety of shapes, angles and curves. Many materials are suitable for our custom roll forming machines,such as produce color steel roof sheets, C/U/Z/M/T/L steel purlins, metal floor deck, cable tray, fire damper, rack pillars ect . We design products that best meet specific needs.

If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to聽build successful business relationships with new clients around the world in the near future.

Company Advantages:

1. Fast Delivery Time聽(25-40 days only)

2. Competitive Price聽(95% suppliers were defeated)

3.聽Good machine Quality聽( Panasonic, Siemens product equipped with our machines)

4. 24h* 7 After-sales聽Service聽(Support Email, Skype, Whatsapp, video meeting ect.)

http://www.roll-formingmachine.net