Coal Grinding Mill Classifier Operation Pulveriser Maintenance Typers Design - No.1-1

Coal Grinding Mill Classifier Operation Pulveriser Maintenance Typers Design For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Coal Grinding Mill Classifier Operation Pulveriser Maintenance Typers Design, Made in China, High Quality Products!, China Coal Grinding Mill Classifier Operation Pulveriser Maintenance Typers Design,Wood Coal Mill Grinder, Supplier, Manufacturer.

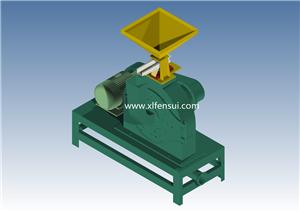

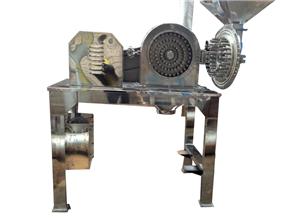

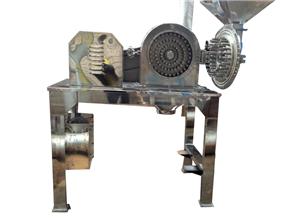

coal grinding mill classifier operation pulveriser maintenance typers designProduct DescriptionThe intracavity of block is cylindrical; it was separated into two parts by a annular plate. The latter half is inlet chamber. The first half is separated to grinding chamber and classify chamber. The grinding chamber is composed of grinding disk and liner,Website:http://www.chinapulveriser.com, to pounding material to powder. The classify chamber is composed of classify impeller, to separate powder to & quot;reach the mark& quot; and not reach the mark. Discharging pipe will aspirate the & quot;reach the mark& quot; powder. & quot;Not reach the mark& quot; powder will go back to grinding chamber through shunting ring to continue to grinding until it is & quot;reach the mark& quot;.Product AdvantageThe machine has simple structure, convenient operation, combustion rate is high, the consumption of less amount of coal, after crushing, coal particle size is fine and uniform, full combustion and consumption amount of coal compared with coal to reduce 30% - 80%, and reduce air pollution, is conducive to environmental protection, and reduce the labor intensity.Working PrincipleCoal grinding machine driving device is composed of a main drive and slow driving device, the normal operation of the main drive for mill, slow drive is mainly used for mill maintenance inspection. Drive slow control mill to rated speed of 1 / 125 of slow rotation. Downtime, not will wear in coal powder emptying, slow drive can drive containing steel cylinder is rotating slowly to prevent deformation of the hot forming and cylinder. Separator through the separator took over and returned to the coal pipe and screw conveyer body is connectedTechnical ParameterModelCapacityPressureVolumnFineness(mm)SpeedPowerkg/hrMM(m3/H)KWWMJ-15020015014000.0526004KWWMJ-20025015015000.0524007.5KWWMJ-25030015017000.05220011KWWMJ-30035015018000.05220011KWWMJ-50060015020000.05240015KWWMJ-60070015025000.05240018.5KWWMJ-1000100015030000.05240022KWApplicationseparator comprises

Get QuoteShengzhou Xinle Pulverizing Equipments Co, Ltd

Address: 38# Luozhong Road, Shanhu District, Shengzhou City, Shaoxing City, Zhejiang Province, China, Shaoxing, Zhejiang, China, 312400

Tel: 86-575-83136228

Established in 1998,Website:http://www.chinapulveriser.com, Shengzhou Xinle Pulverizing Equipments Co., Ltd (Xinle Company) is a manufacture of pulveriser, mill and grinder. Which are widely used in food & spice, chemical, medicine, rubber and plastic, graphite and etc. Especially our machine is quite suitable in sugar, garlic, onion, chili, ginger, LDPE, HDPE, PVC, tire rubber, etc. We start to export our machine since 2007. We have customers in India, Pakistan, Greece, UK, Syria, Spain, Vietnam, Bangladesh, Ghana, Ecuador, etc. More than 58% customers will reorder after they use our pulveriser. More than 30 workers with advanced equipments warmly welcome to visit our company!

http://www.chinapulveriser.com