CNC Milling Machine Parts / Aluminium Turned Auto Parts , Ran Out 0.005mm - CAAP

CNC Milling Machine Parts / Aluminium Turned Auto Parts , Ran Out 0.005mm For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale CNC Milling Machine Parts / Aluminium Turned Auto Parts , Ran Out 0.005mm, Made in China, High Quality Products!, China cheap prodocuts, china suppliers Supplier, Manufacturer.

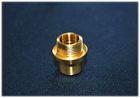

High Precision CNC Turning and Milling Aluminium Turned Auto Parts, Ran-out 0.005mm

?

?

Specifications:

?

- - - -

Technical Parameter for High Precision CNC Turning and Milling Aluminium Turned Auto Parts, Ran-out 0.005mm | Diameter | 5~500mm |

Tolerances | +/- 0.005mm |

Material use | Aluminium 6061 |

Processing | CNC Milling, CNC Turning |

Run-out | 0.005mm |

Flatness | 0.005mm |

Perpendicular | 0.005mm |

Cylindricity | 0.005mm |

Type Of Service: | ? | OEM or ODM |

- - - -

?

Description:

Hantech Precision-- Your Reliable Precision Parts Supplier

* Manufacturing and servicing of CNC machining parts, customize or tailor made machining parts, Precision CNC machining service and die casting parts.?

* To provide a Total Solution services for our customers, starting from product design, material sourcing to finished products.

?

- - - -

Product Application | # small parts as follow: # connector, # spindle, # shafts, # stainless steel fittings,? # wheel studs, # cell phone, # medical devices, # optical equipments, # automobile, # optical communication, # lighting industry , # office equipment, etc |

Industry Involved | # # Aerospace industry, # Automation, # marine industry, # military industry, # medical equipment, # electronic equipment, # telecommunication, # optical communication and etc. |

- - - -

?

Why choose HanTech Precision?

1. Strict Quality Control

* Ttrained ourselves and capable to provide high quality and tight tolerance precision machining parts service for worldwide customers.

* Our commitment to deliver problem-free products and on time delivery.

?

2. Effective and Efficient Project Management

*? A good management concept, including effective of scheduling of the workflow, good communication internally and also with customer and good control of the manufacturing process.

* Asigned an experienced project engineers to the customer from initial to end until mass production.

* For each of the projects,? review the entirely project starting from design stage and come out with the detailed DFM(design For Manufacturing) plan.

*? also estimate the? progress schedule.

* Adopt thw transparency of project management and fast response to our customer.

?

Customer Service:

* based on effectiveness of two-way communication and a quality service to our customer.

* Value our customer feedback which we believe customers have valuable opinion to share with us.

* Ensure ourself that we are accessible to them before, during and after project is completed.

* Stress on our internally communication.

From prototype, design, assembly, as well as information sharing with customer, we are providing a total solution for our customer.

?

?

?

Service

* Provide one-stop precision machining service ?to our customers.

* Our parts are mostly used in the field like automotive, automation system, special purpose machinery, medical equipment,electronic ?equipment,fluid control,lighting industry, optical industry,model manufacturing,etc.

* wide range of machining service using advanced equipments and latest technology including:

CNC Milling Service

CNC Turning Service

CNC Milling and Turning Multiple

Mechanical Parts Design

Precision Grinding

Auto-Lathing Turning

Die Casting

?

- - - -

Process | Axis | Capability |

# CNC Milling # CNC Milling # CNC milling-turning # Custom Machining | # 3 axis to 4 axis machine | # Accuracy of holes : 0.005mm, # Accuracy of dimension :0.005mm, # Accuracy of center distance: 0.01mm |

- - - -

?

The material we mostly machining:

Metal:Stainless Steel,Aluminium,Brass,Bronze,Copper,Steel,etc.

Plastic:POM,ABS,PTFE,PC,PP,Nylon,Teflon.PVC,Acrylic,Acetal,etc.

?

The surface treatment we can do:

Anodizing

Heat treatment

Chemical conversion coating

Plating(Zinc,Nickel,Gold,Silver,Chrome,Oxidize,etc)

?

- - - -

Competitive Advantage | Total Solution Provider | ? Our Winning strategy: ? |

# Top Quality # Competitive Price # On Time Delivery # Excellence Customer Service | # Service Provide starting from material sourcing, product design and finished products shipment, inclusive supply chain management (ODM/OEM). | # Providing value-added engineering service. # Assisting you from material choosing, structure testing, process, up to finished goods arrangement. # One-stop custom machining services. |

- - - -

?

?

HanTech Precision Electronics Co., Ltd.

Address: N0:2, Yangxian Road, Suzhou Industry Park, Suzhou, Jiangsu, China, 215000

Tel: 86-512-80983758

Background

HanTech鈥檚 group is professional in CNC Precision Machining Parts. We are ISO9001 certified and also rewarded as Strategic Partner for Military Product from our customer. In order to enhance ourselves better, we are practicing ISO/TS16949 Automobile Standard in our operation, targeted to be certified by Q4 this year.

We are providing a Total Solution for Precision and Die-casting process for Automobile (Auto) / Automation, Telecommunication, Optical Communication, Aerospace, Medical, Electronic and Military industry.

HanTech鈥檚 professionals are all well trained, and prepared to work with customer for new product development, improvement and mass production. Due to our outstanding performance including in technology, price competitiveness, quality, and customer service in SuZhou City, JiangSu Province of China. As the result, we are proud to become the partners for those well-known companies in China, as well as the world famous automobile companies.