Circle Downpipe Roll Forming Machine - 13136

Circle Downpipe Roll Forming Machine For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Circle Downpipe Roll Forming Machine, Made in China, High Quality Products!, China circle downpipe, cold roll forming machine Supplier, Manufacturer.

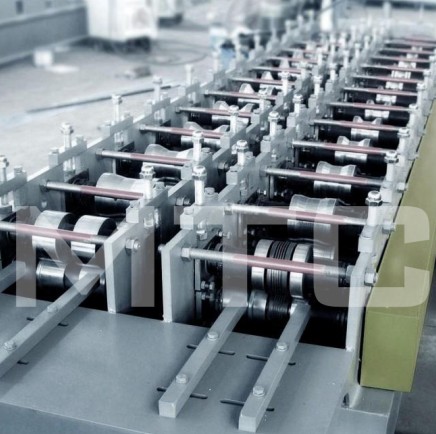

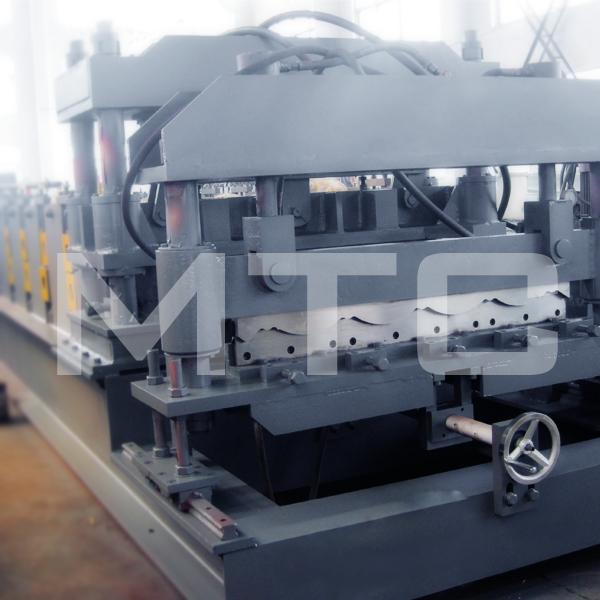

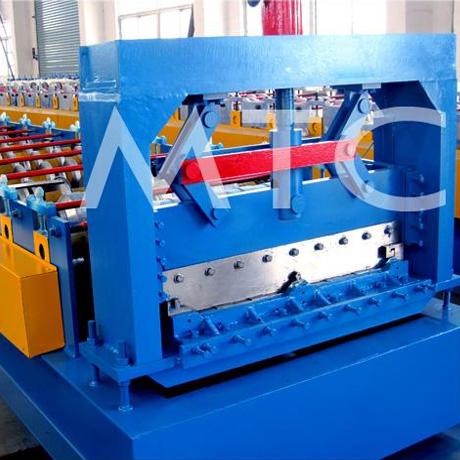

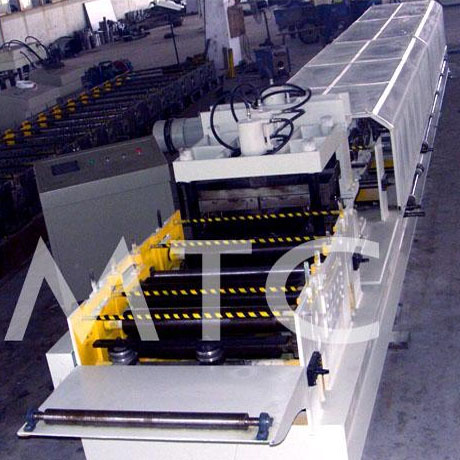

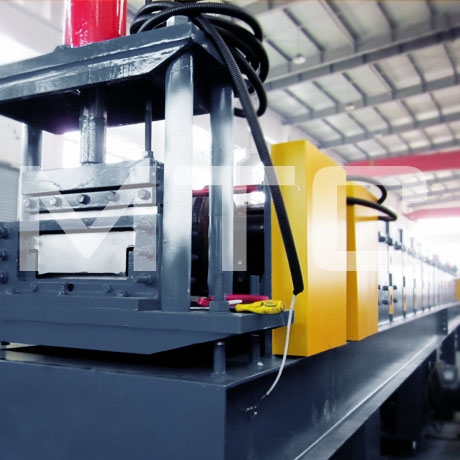

Our downpipe roll forming machine,or rainwater pipe roll forming machine base is whole welding treatment from H-beam steel, and with the frame on the both sides of the downpipe roll forming machine,or rainwater pipe roll forming machine is also welded on the machine base and we can get ride of welding stress by shaking.The whole downpipe roll forming machine,or rainwater pipe roll forming machine is single station with chain transmission, so the machine will work safely and stably with small internal friction.

Product features

Brief Introduction of Circle Downpipe Roll Forming Machine,Rainwater Pipe Roll Forming Machine:

Raw Material that our downpipe roll forming machine handles:

Material Thickness: 0.45-0.6mm

Decoiler for the round downpipe roll forming machine:

Decoiler Type: Manual Decoiler

Weight Capacity: 3 Ton

Main motor power: 7.5Kw

Number of roll stand: About 26 stands

Forming speed: 6-12m/min

Voltage: 380 V, 3 Phase 50Hz

Dimension of machine: About 12000mm*1100mm*1200mm

Machine wight: about 12 Ton

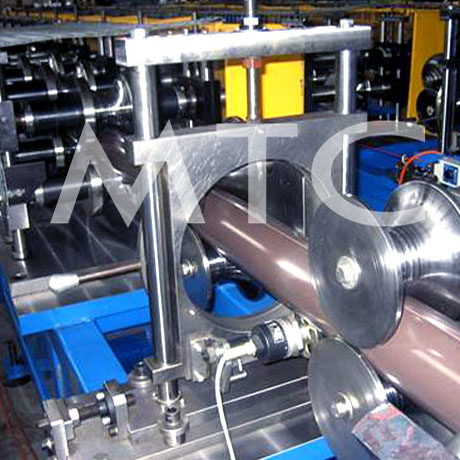

Material of Axis: High grade 45# steel

Diameter of Axis: φ75mm;

Material of Roller: High grade 45#, polished and coated with 0.05mm chrome Surface.

Type of forming machine: chain-gear transmission

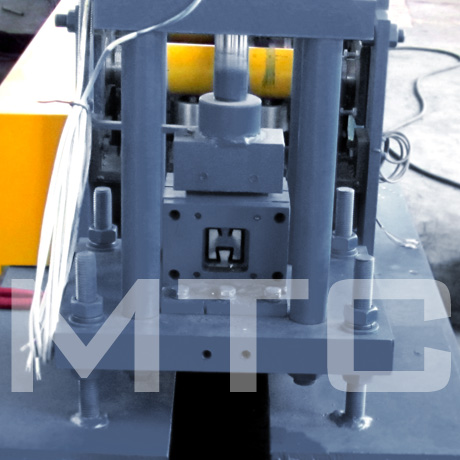

Cutting Device for the circle downpipe roll forming machine or rainwater pipe roll forming machine:

Cutting Type: Flying Saw Cutting

Motor power: 5.5KW

Electrical Control system of the circular downpipe roll forming machine:

Adopts PLC control technology, frequency adjust speed technology, realize the automatic production.

Operation type: Touching screen + Button

Using encoder to calculate the number and measuring the length

Electrical Control: PLC Frequency Control System with touch screen

PLC Brand: MITSUBISH or PANASONIC Brand

Size of PLC Control Board: 700mm(L)x1000mm(H)x300mm(W)

Website:www.mtc-china.com

Tel:86-21-67228332

Fax:86-21-67228302

Shanghai MTC Industrial Co.,ltd

Address: XingTa Industry Park,Jinshan District, Shanghai of China. , Fengjing , Shanghai, China, 201501

Tel: 0086-21-67228332

About Our Company:

MTC (Maxon Technology Corp.) is specialized in designing and manufacturing various cold roll forming machines and insulated sandwich panel production lines in China. With the development of the new age,MTC now presents the most advanced and innovative technology in its main products,such as roll forming machines, insulated sandwich panel production lines,slitting and cut-to-length machine lines,hydraulic decoilers,and some auxiliary machines etc.

About Our Service:

WE HAVE CE CERTIFICATE FOR OUR MACHINES AND PROVIDE 2 YEARS OR 5800 WORKING HOURS WARRANTY FOR OUR EQUIPMENT SINCE DELIVERY. In case of any damages or defects caused by the quality of our production technology,we will take in charge of any breakdowns within the warranty and we will provide duly service for maintenance in the whole life circles of the machines. Technicians will be sent to make installation and to train your craftsmen how to operate the machine until they can operate the machine proficiently.

About Our Culture:

Business Mission: Make True Change.

True change will be made, not only said, to enable our partners have a better experience with us.

Business Principles: Quality First, Service Next, and Money Last.

Only quality and service were greatly satisfied, would partners be pleased to buy one more time.

Business Values: Coordination,Circumspection and Innovation.

There is no "I" in MAXON, only coordinated with each other, and being circumspect, our team could innovate satisfactory products for our partners.