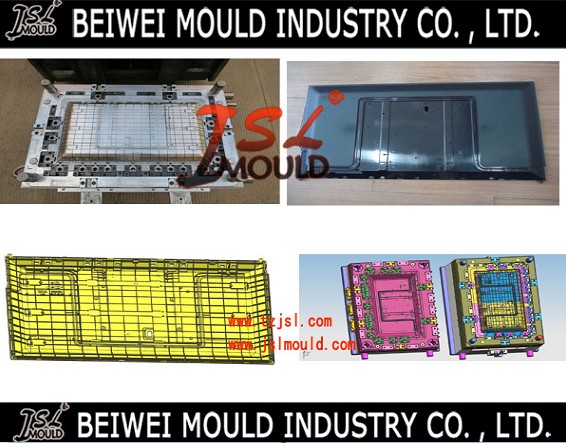

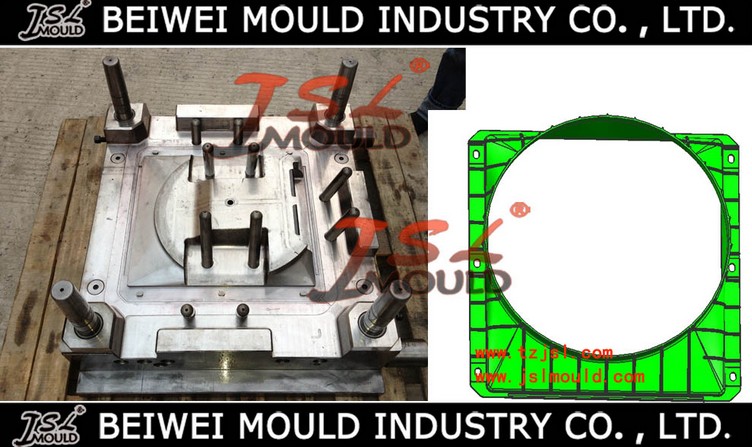

China rice cooker mould manufacturer - jsl-t18

China rice cooker mould manufacturer For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale China rice cooker mould manufacturer, Made in China, High Quality Products!, China rice cooker mould , rice cooker mold Supplier, Manufacturer.

Product Name China rice cooker mould manufacturer

Product material PP

Core&Cavity Steel 2738

Steel hardness HRC35-38

Mould Standard DME

Cavity Number Single or Mutil

Injection System side gate/point gate/direct gate

Ejector System ejector pin/ejector plate/ejector block

Cycle Time 20-40s

Tooling lead time 60 days

Mould life more than 500,000shots

Quality assurance ISO9001

Our Advantage 1.High quality

2.Reasonable price

3.On time delivery

4.Good After-sale service

5.Strict quality control

6.All the mould are automotic.

Offer you In-time response on letters, telephone calls or fax

In-time supply the quotation and mould designs

In-time communication on the technical points

In-time sending pictures for the mould machining progress and mould finishing schedule

In-time mould test and sample delivery

In-time mould delivery.

For more information please contact us.

Taizhou City Huangyan Beiwei Mould Industry Co., Ltd.

Address: No.20, JinChuan Road,Industrial and Developed Area, Taizhou, Zhejiang, China, 318020

Tel: +8618367693499

BeiWei Mould Industry Co.,ltd is the leading plastic moulds manufacturer in China, Based on the precision tooling, high technology and top mentality mould design. Jsl Industry has established the main market in Spain,Brazil, Sweden,Australia,Ireland,U.S.A and etc.

Our products covers Plastic injection molding,Plastic blow molding,BMC/SMC/DMC/GMT glass fiber mold,Plastic injection molded products and Metallic punch products.

We use Pro-E, Solidworks, U.G., and Auto-CAD for moulds and products design, with very strong mould design and drawing reading ability. This ensures the good technical communications with clients, which can avoid any mistake occur.

We have utilized modern equipment such as CNC machining center, EDM machine and EDM wire cutting machine. Modern CAD/CAM/CAE systems, such as those using UG, ProE, Solidworks and Cimatron, are also in place to assure the quality of our molds and molded products.

Our mission is to provide our customers high quality products and services. We aim to exceed our customers鈥?expectations in terms of pricing, quality and on-time delivery.